Nozzle cooling vacuum gas quenching furnace capable of convection heating

A technology of convection heating and vacuum air, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of uneven furnace temperature and large heat loss of fixed return air outlet, improve heating speed and uniformity, and excellent cooling performance , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

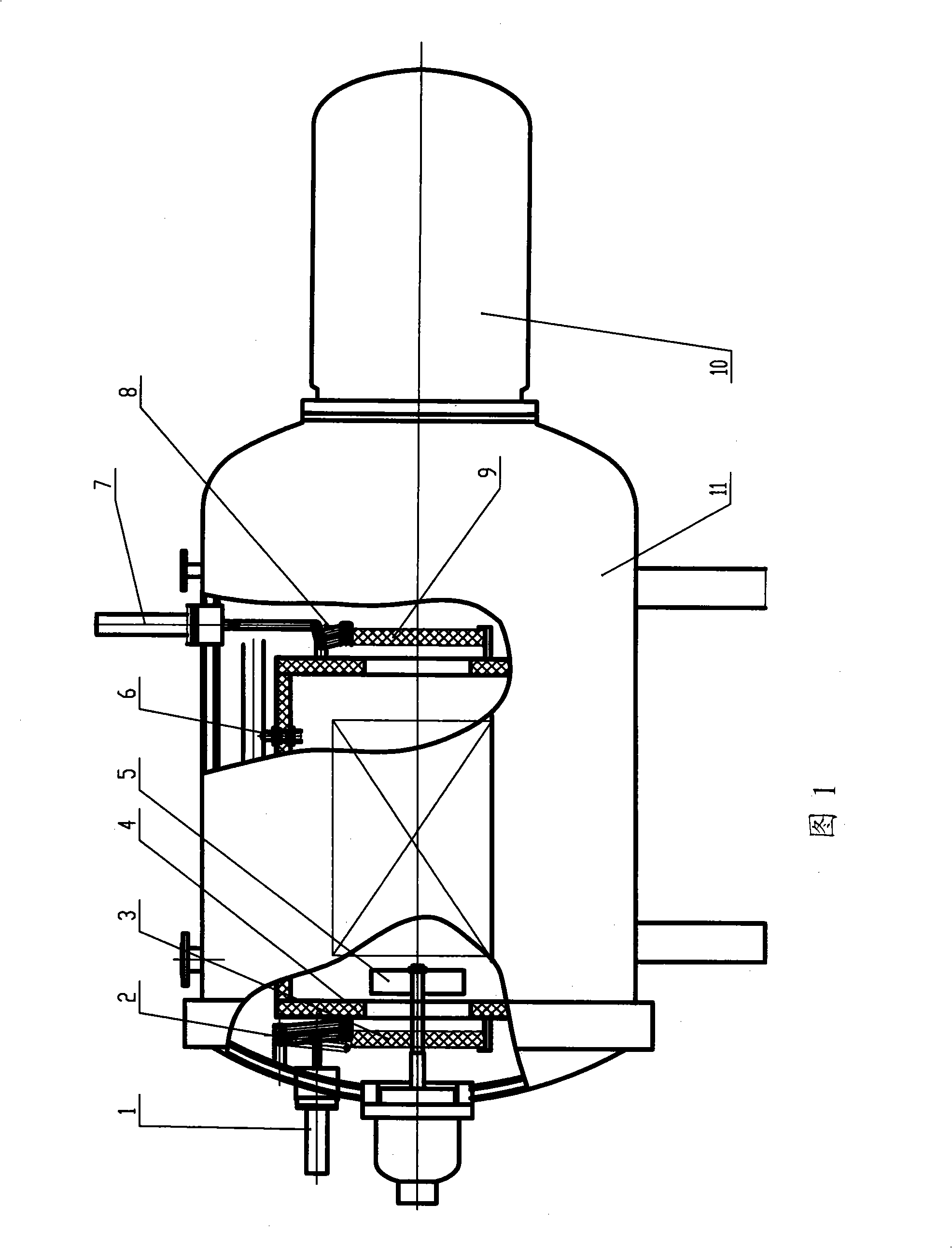

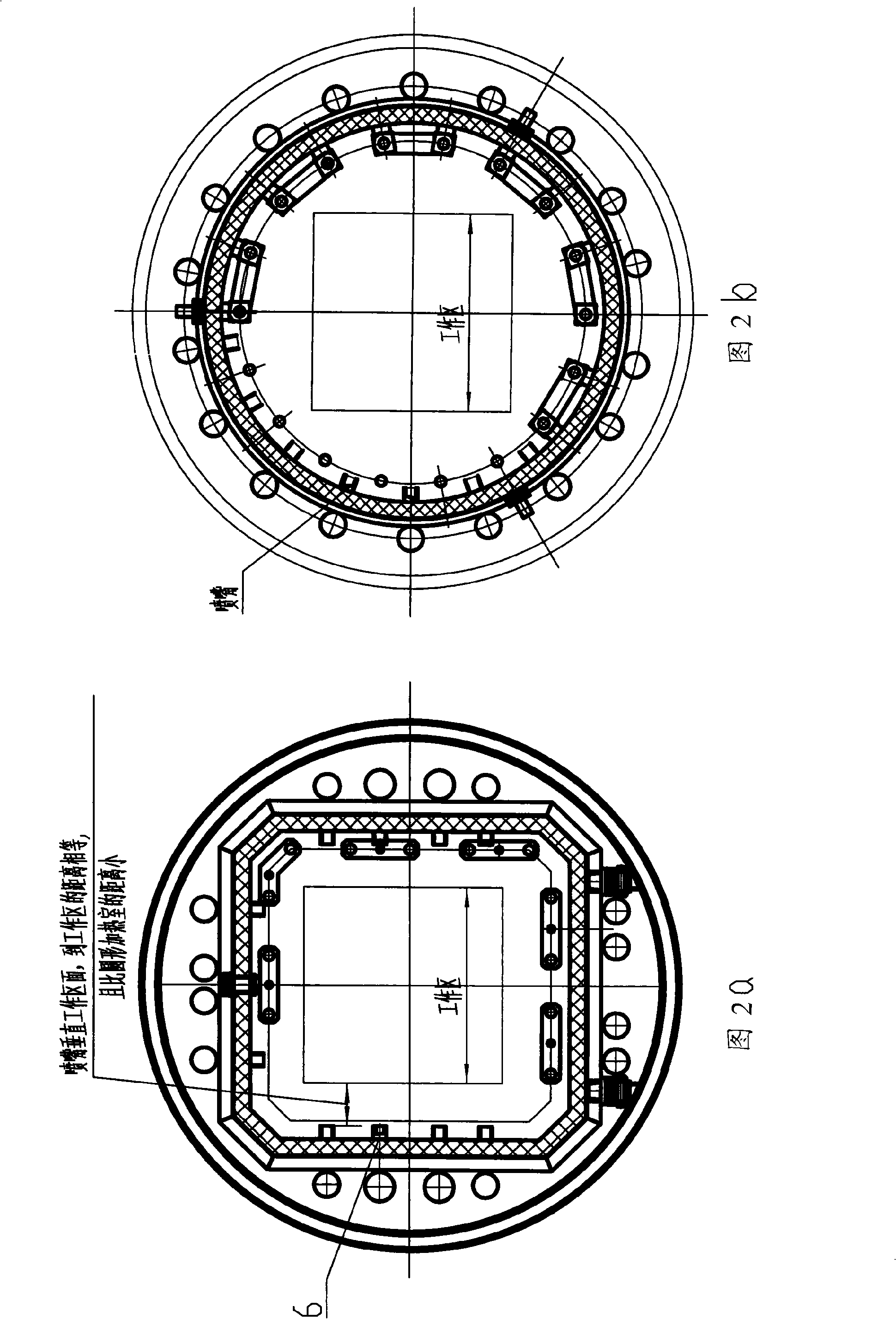

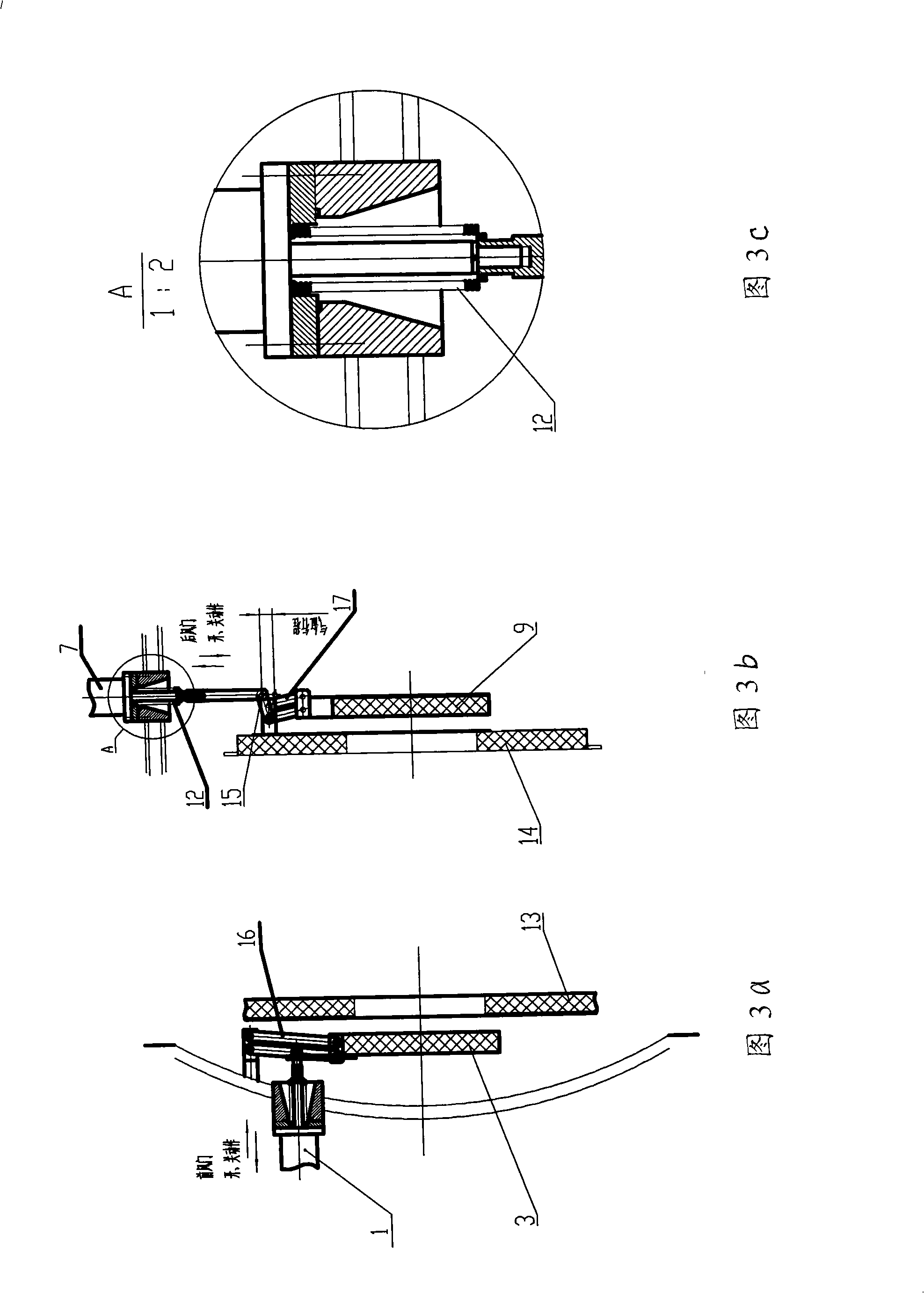

[0013] The convective heating nozzle cooling vacuum air quenching furnace of the present invention is shown in Figure 1. The furnace shell 11 is a cylinder, and a cooling fan 10 is arranged at one end. The axial direction of the furnace body is parallel to the ground, and an automatic control system is adopted. The heating chamber 4 inside the shell is a square structure, as shown in Fig. 2a. The cooling air ducts and nozzles 6 are arranged around the square heating chamber, and the nozzles 6 are perpendicular to the surface of the central square working area. The front and rear ends of the heating chamber 4 axially have return air outlets, and the air return openings have openable and closable dampers 3,9. Fan motor etc. are all contained in the furnace shell 11, no longer need sealing. Can open and close damper 3,9 all adopt the opening and closing damper structure of parallelogram, and establish respective door-opening cylinder 1,7, the seal that cylinder introduces furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com