Low-voltage high power multi-branch three phase asynchronous motor

A three-phase asynchronous, high-power technology, applied to the shape/style/structure of the winding conductor, can solve the problems of low voltage, low representativeness, high power, etc., achieve reliable working performance, avoid instability, prolong The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

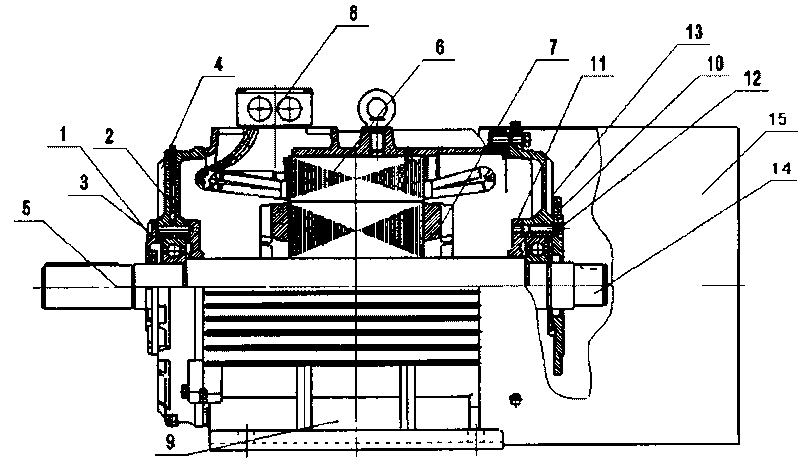

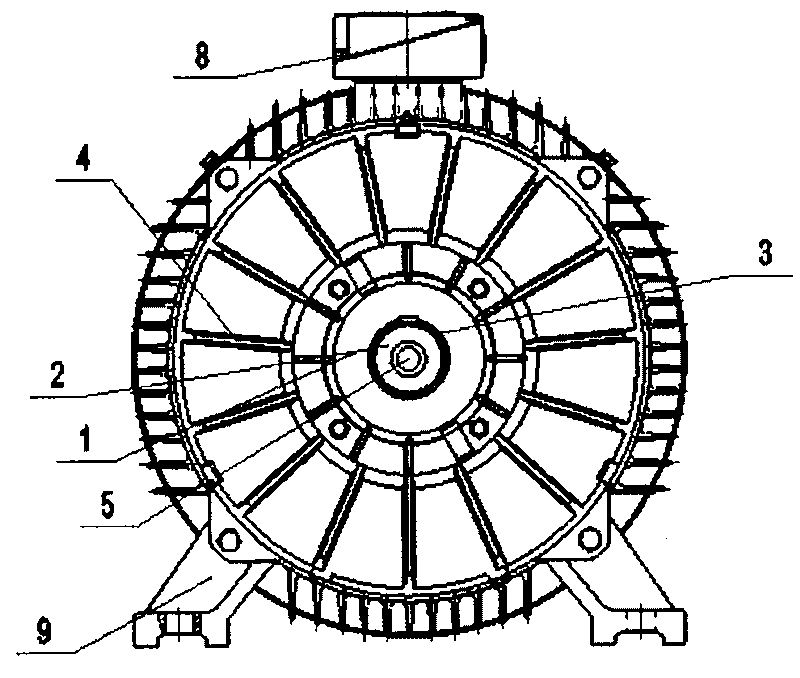

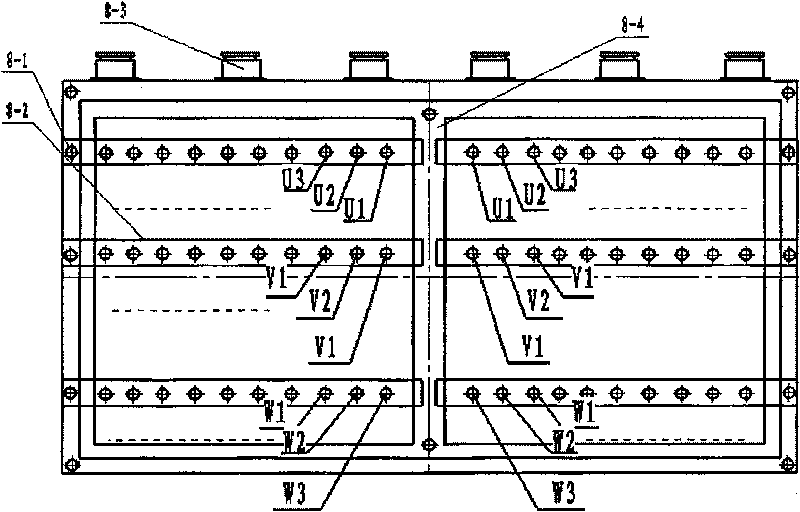

[0019] The low-voltage high-power multi-branch three-phase asynchronous motor consists of a machine base 9, a left bearing outer cover 1, a left bearing inner cover 2, a left bearing sleeve 3, a left end cover 4, a left bearing 5, a stator 6, a rotor 7, a junction box 8, Right bearing outer cover 10, right bearing inner cover 11, right bearing sleeve 12, right end cover 13, right bearing 14, fan cover 15, left bearing outer cover 1 and left bearing inner cover 2 are installed on the left bearing sleeve 3 by bolts, The left bearing sleeve 4 is installed on the left end cover 4 with bolts, the left end cover 4 and the junction box 8 are respectively installed on the machine base 9 through bolts, the left bearing 5 is installed on the rotor 7, the stator 6 is directly installed on the machine base 9, and the rotor 7 Through left bearing outer cover 1, left bearing inner cover 2, left bearing sleeve 3, left end cover 4, left bearing 5, right bearing outer cover 10, right bearing in...

example 2

[0022] The electromechanical structure is the same as Example 1, in which the star-shaped three-phase sub-winding is equal to the number of poles of the motor.

example 3

[0024] The electromechanical structure is the same as Example 1, in which the star-shaped three-phase sub-winding has three times the number of poles of the motor.

[0025] The present invention is powered by a power frequency power supply, such as Figure 4As shown, the low-voltage high-power asynchronous motor is mainly controlled by the contactor KM to control the power on and off of the three-phase winding 1-8, so that the working three-phase winding and the motor load can achieve the best match, and the reduced motor current protects the drive system. The role of the contactor, the contactor KM can also be controlled by CPU technology such as PLC (or single-chip microcomputer).

[0026] In the frequency conversion speed regulation system of the present invention, Figure 5 Reasonably configure general-purpose low-voltage frequency converter VVVF according to requirements, and the quantity and type of general-purpose low-voltage frequency converters should be reasonably s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com