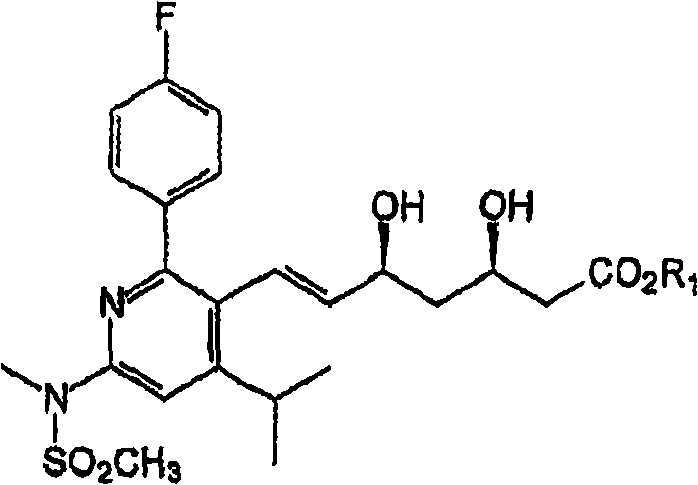

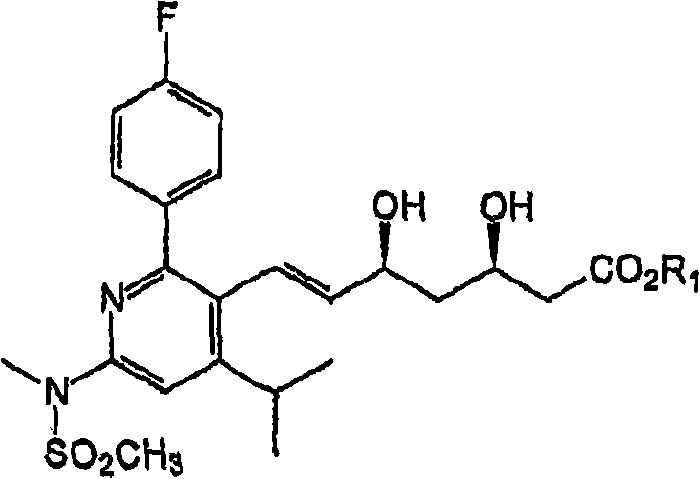

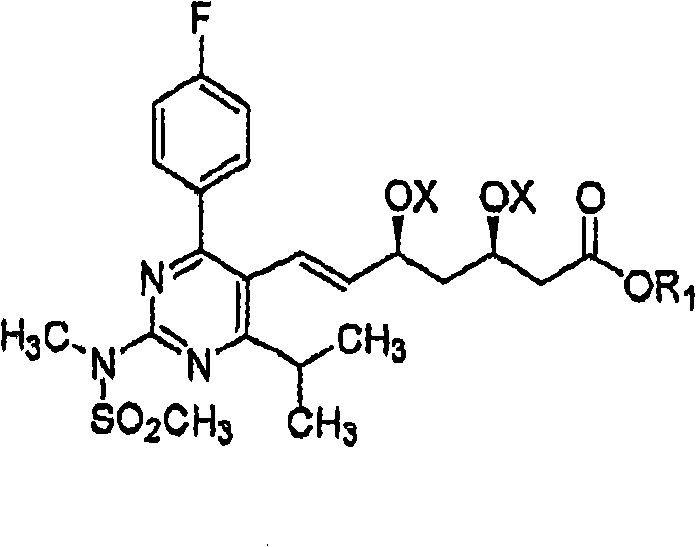

Diastereomeric purification of rosuvastatin

A kind of rosuvastatin, diastereomer technology, applied in the field of rosuvastatin intermediate and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0096] Example 6 illustrates the use of ammonium chloride during the work-up of the reaction. The use of ammonium chloride helps in the use of H 2 o 2 Dissolution of the salt formed after quenching the reaction. The use of ammonium chloride partially dissolves the salt in the aqueous layer. The remaining salt can then be removed by filtration. Washing with a mixture of water and brine removes the H 2 o 2 The impurity octanediol formed after the reaction is quenched (decomplexation of OMe-9-BBN). H relative to TB21 or other esters 2 The O / NaCl ratio is preferably about 10 / 10 by volume. A second wash is preferably performed where H is preferred relative to TB21 or other esters 2 The O / NaCl ratio is about 10 / 2 by volume.

[0097] Preferably, the water-immiscible solvent is selected from C 4 -C 7 Esters and C 6 -C 10Aromatics. Preferably, the solvent is selected from ethyl acetate, toluene, methyl ethyl ketone and mixtures thereof. More preferably, the solvent is et...

Embodiment 1

[0169] Example 1: DEMB reverse addition, according to US 5,189,164

[0170] A 25 ml flask equipped with a nitrogen bubbler and a magnetic stirrer was charged with TB21 (1.0 g), tetrahydrofuran (0.35 ml) and methanol (0.1 ml) to form a suspension. The suspension was stirred at room temperature to obtain a clear solution.

[0171] A 50ml 3-necked flask equipped with a mechanical stirrer and a nitrogen bubbler was charged with tetrahydrofuran (4.4ml) and methanol (1.2ml) and cooled to -78°C. Add NaBH 4 (0.192g), then diethylmethoxyborane (2.05ml, 1M solution in THF) was added, and the resulting mixture was stirred at -78°C for 10 minutes.

[0172] Add the solution of TB-21 to the NaBH via syringe over a period of about 1.5 hours 4 and diethylmethoxyborane to form a reaction mixture. The reaction mixture was stirred at -78°C for 30 minutes. Join H 2 o 2 (0.8ml, 30%), the reaction mixture was allowed to reach room temperature and then evaporated to dryness to obtain a resi...

Embodiment 2

[0174] Example 2: Reverse addition of a solution of DEMB in 60 volumes of solvent

[0175] A 50 ml flask equipped with a nitrogen bubbler and a magnetic stirrer was charged with TB-21 (1.0 g), tetrahydrofuran (3.5 ml) and methanol (1.0 ml). The resulting suspension was stirred at room temperature to obtain a clear solution.

[0176] Into a 50 ml 3-necked flask equipped with a mechanical stirrer and a nitrogen bubbler, tetrahydrofuran (44.0 ml) and methanol (12.0 ml) were charged to obtain a mixture. The mixture was cooled to -78 °C, NaBH was added 4 (0.192g) followed by the addition of diethylmethoxyborane (2.05ml, 1M in THF). The resulting mixture was stirred at -78°C for 10 minutes.

[0177] The TB-21 solution was added to this mixture via syringe over a period of 1.5 hours to form a reaction mixture, which was then stirred at -78°C for 30 minutes. Join H 2 o 2 (0.8ml, 30%) and the reaction mixture was allowed to reach room temperature. The reaction mixture was evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com