New method of biologically synthesizing (R)-3-hydroxylglutarate monoester

A technology for hydroxyglutaric acid monoester and hydroxybutyric acid monoester, which is applied in the fields of biocatalysis to prepare pharmaceutical intermediates and green chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

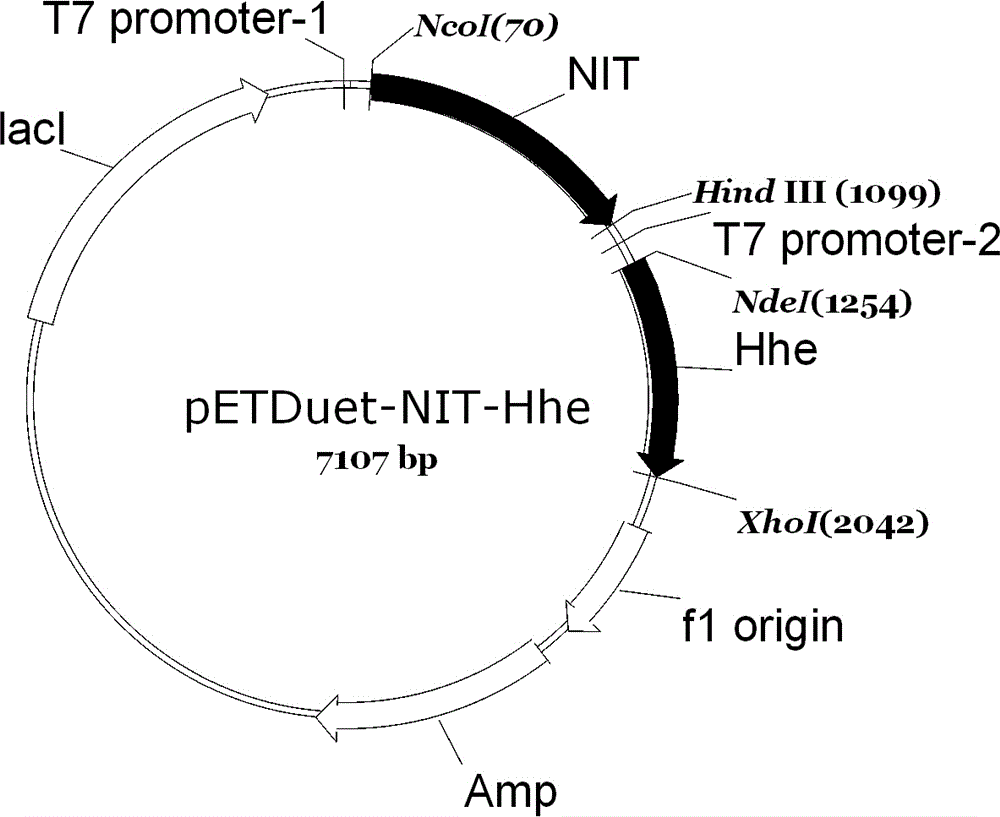

[0050] Example 2 Acquisition of genetically engineered bacteria that co-express halohydrin dehalogenase and nitrilase

[0051] According to standard methods, the above-mentioned halohydrin dehalogenase and nitrilase were constructed into the same pETDuet-1 vector. The structure of the double-enzyme co-expression plasmid for halohydrin dehalogenase and nitrilase is shown in Fig. figure 1 shown. The obtained co-expression vector is transferred into Escherichia coli BL21, Rosetta or Origami by conventional methods to construct co-expression genetically engineered bacteria, and screened out genetically engineered bacteria that have been established successfully. Preferably, the co-expressed genetically engineered bacteria are stored in the form of glycerol bacteria or milk freeze-dried bacteria.

Embodiment

[0052] Example 3 Cultivation of genetically engineered bacteria and preparation of resting cells

[0053] Pick a single colony on the plate and inoculate it into 5 ml of fermentation medium containing the corresponding antibiotics, cultivate it for about 15 hours as a seed solution, and inoculate it into 600 ml of fermentation medium according to the inoculum of 1%, at 37 ° C, 200 rpm on a shaker to OD 600 =0.6-0.8, add IPTG with a final concentration of 0.1 mM for induction at 25°C for more than 10 h, and centrifuge the culture medium at 8000 rpm to collect the bacteria.

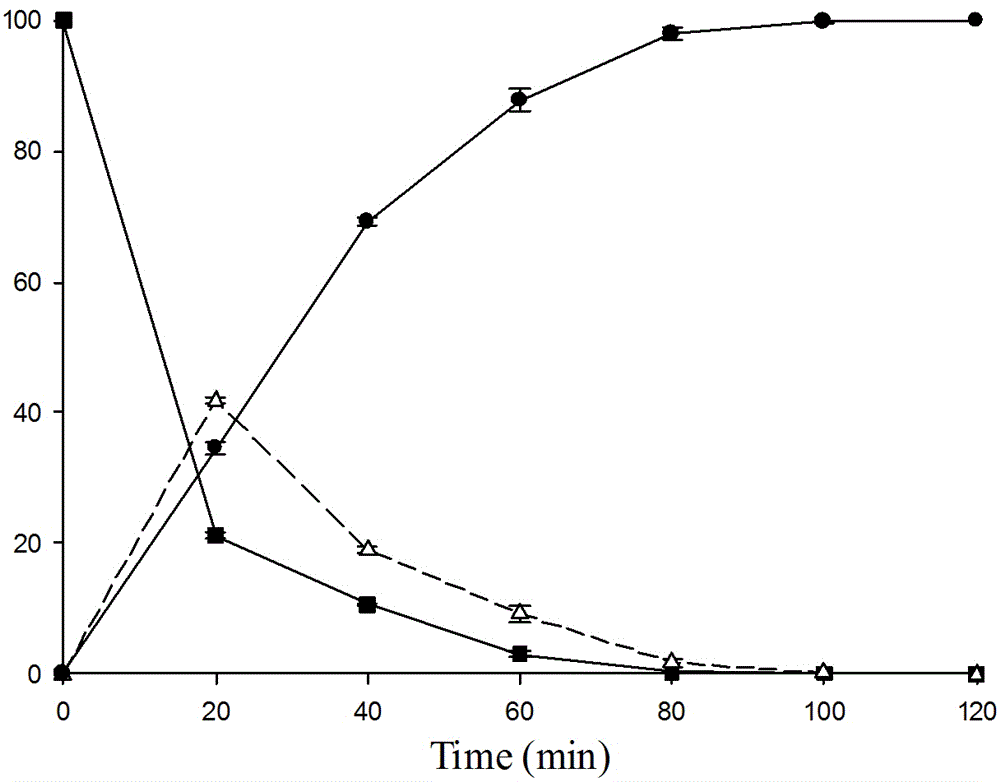

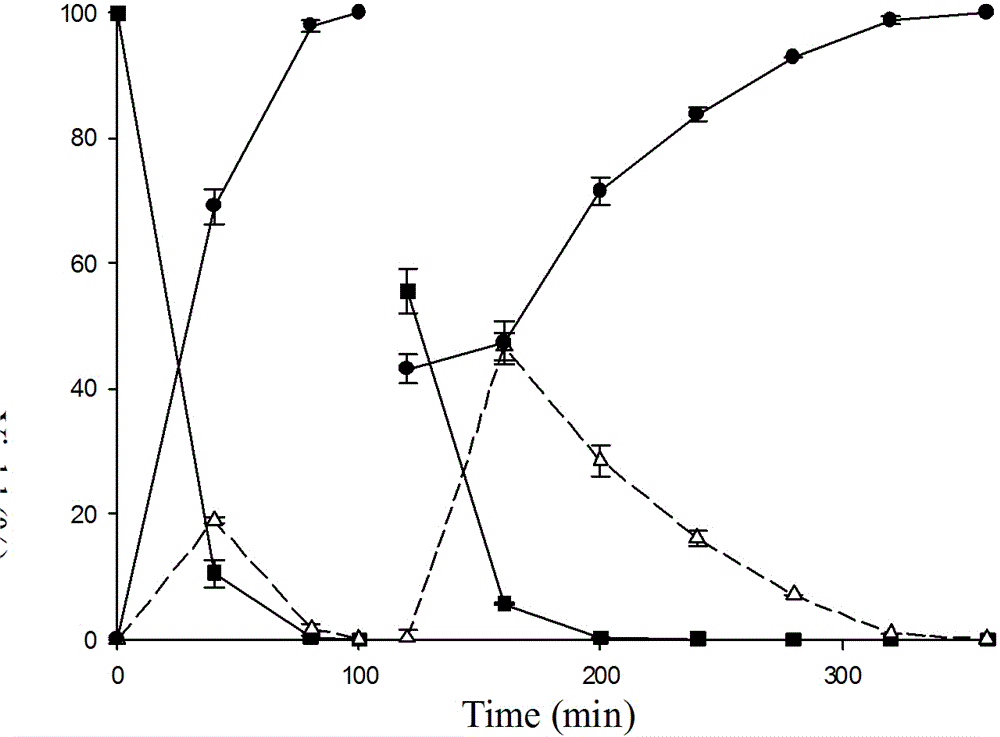

[0054] Example 4 Co-expression recombinant bacteria resting cell synthesis ( R )-3-hydroxyglutaric acid monoester - a single input substrate

[0055] Take 3.0 g of resting cells (wet weight) of co-expressing genetically engineered bacteria and resuspend in 50 ml sodium phosphate buffer (50 mM, pH 8.0), add ( S )-4-chloro-3-hydroxybutyrate (2.5 g, 15 mmol), then utilize the pH on-line control system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com