Magnetorheological finishing device for high-steepness optical part

A technology of magnetorheological polishing and optical parts, applied in the field of magnetorheological polishing, can solve the difficult problem that cannot be solved in the processing of high-steep optical parts, the curvature radius of high-steep parts changes drastically, and is not suitable for the processing of high-steep optical parts and other problems, to achieve the effect of wide application, simple and compact structure, and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

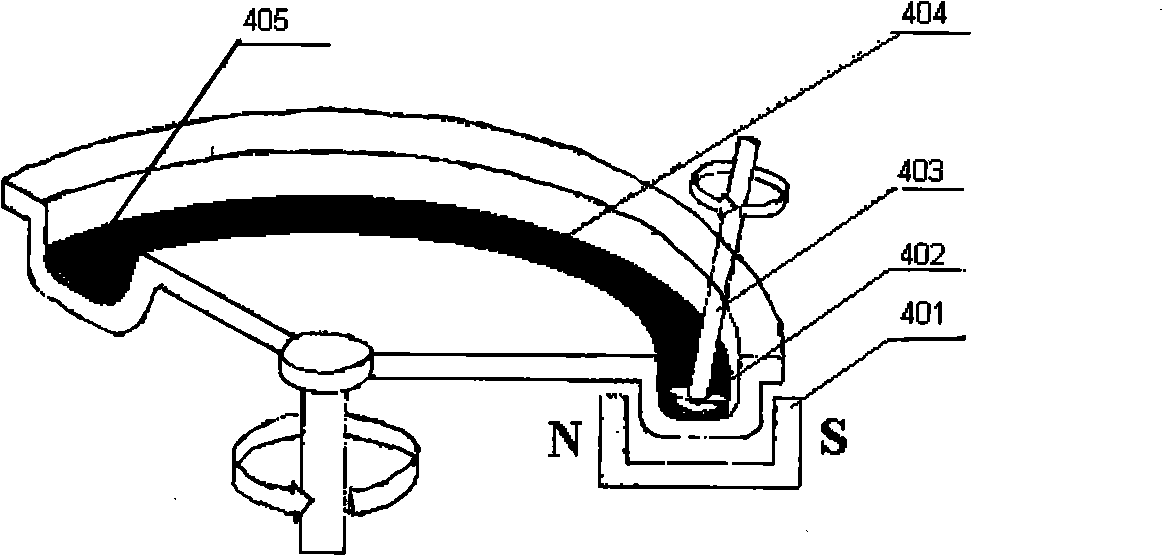

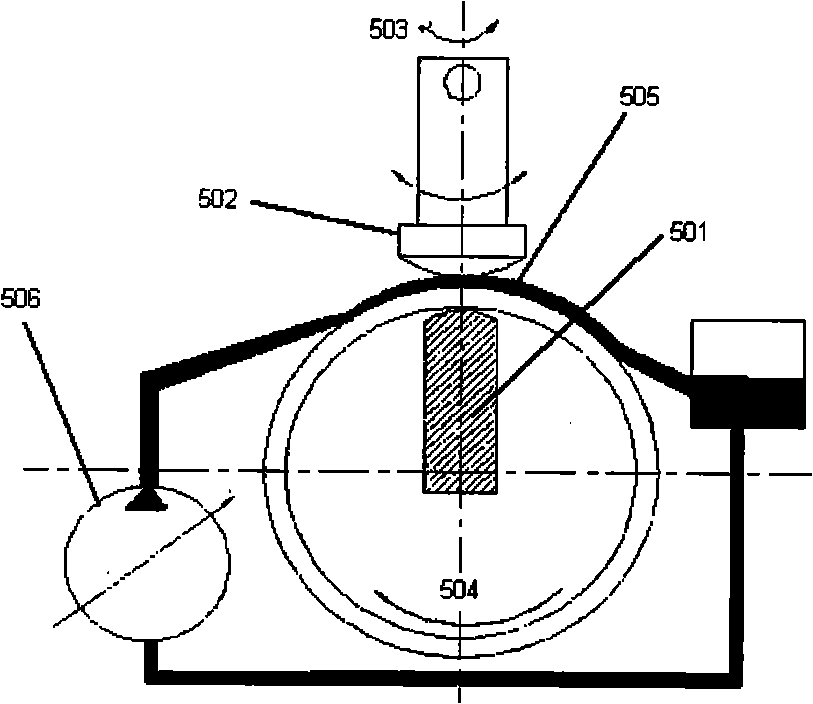

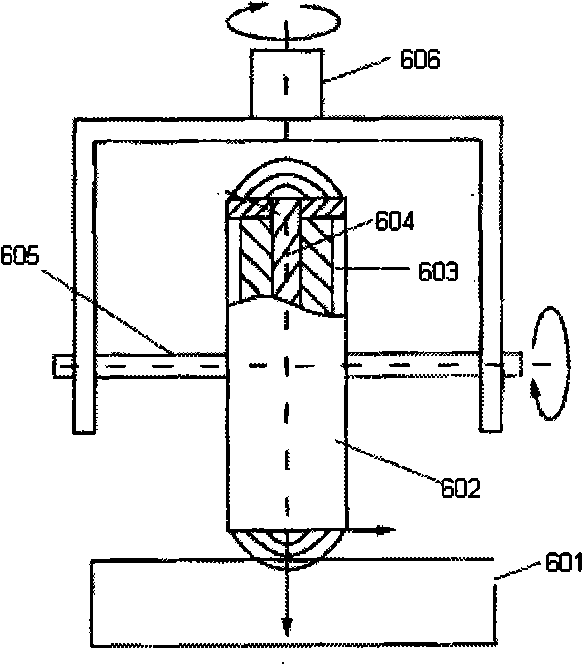

[0064] see Figure 4 As shown, the present invention is used for the magneto-rheological polishing device of high-steep optical parts, which includes a machine tool 1, a magneto-rheological polishing device 2 and a control system connected to each of the above components respectively. The bed 101 of the machine tool 1 is in the shape of "L" ” shape, which includes a horizontal base and a vertical base. The X-axis linear motion mechanism 102 and the Y-axis linear motion mechanism 103 are arranged on the horizontal base in a “cross” shape, and the X-axis linear motion mechanism 102 is fixed on the Y axis. On the slider of the Z-axis linear motion mechanism 103, the Z-axis linear motion mechanism 104 is arranged on a vertical base. On the block, the B-axis rotary table 106 used to install the workpiece fixture 109 is fixed on the slider...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com