Multicomponent compounds infrared crystal growth apparatus

A crystal growth and compound technology, applied in crystal growth, single crystal growth, post-processing devices, etc., can solve the problems of solid-liquid interface drift, small temperature gradient, large difference in melting point, etc., to achieve complete appearance, good crystallization performance, The effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

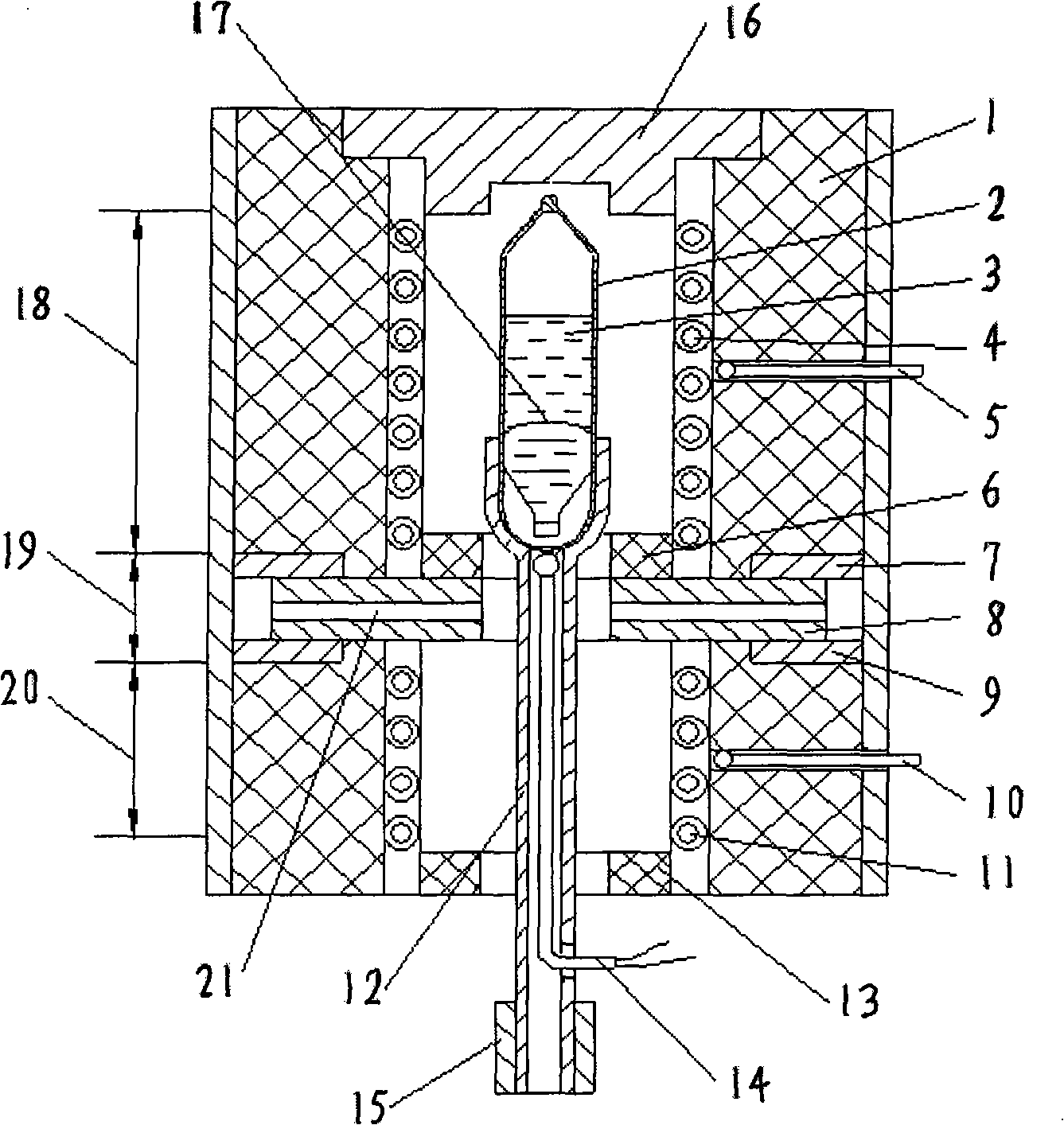

[0017] The multi-component infrared crystal growth device of the present invention is as figure 1 As shown, the furnace body 1 is included, and the insulation material is filled between the shell of the furnace body 1 and the furnace. The furnace in the furnace body includes three parts from top to bottom: the upper high temperature zone 18 , the middle gradient zone 19 and the lower low temperature zone 20 . The top of the furnace is provided with an insulating cap 16 made of high-alumina refractory bricks for closing the furnace, which can effectively prevent the "chimney effect" and ensure a constant temperature in a large range of high-temperature areas, which is conducive to the melting and melting of polycrystalline raw materials. Uniformity. A heat insulating ring 13 is added at the bottom of the furnace to prevent heat loss caused by heat transfer to the atmosphere, maintain the stability of the temperature field in the low temperature zone, and ensure constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com