Underwater hydraulic reversing valve

A hydraulic reversing valve and hydraulic technology, which is applied in the field of hydraulic control valves and valves for deepwater drilling well control devices, can solve the problems of equipment not being able to meet offshore development, equipment dependence on imports, and slow development, so as to facilitate product serialization and structure Compact, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

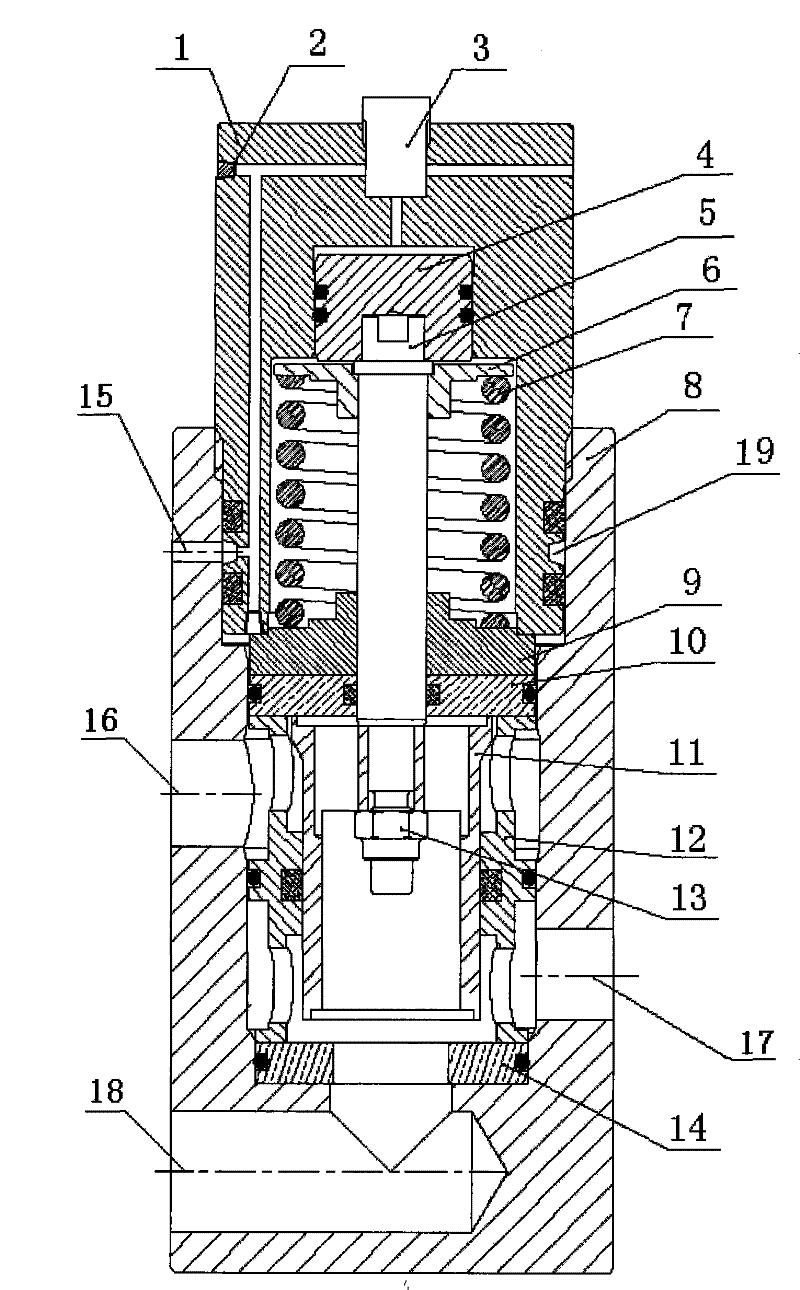

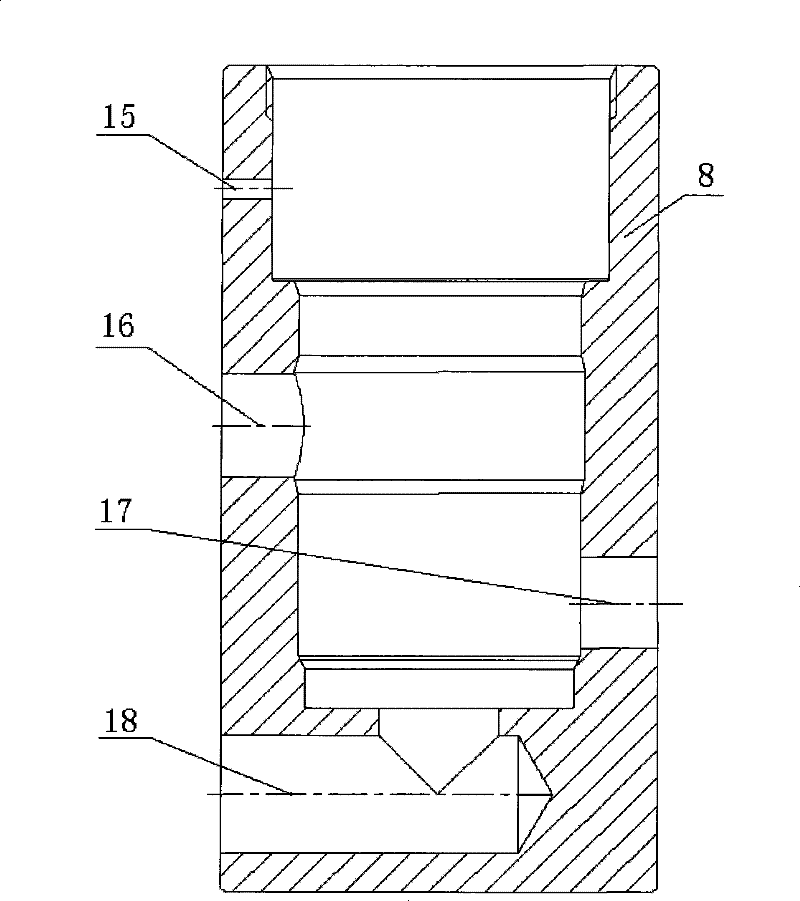

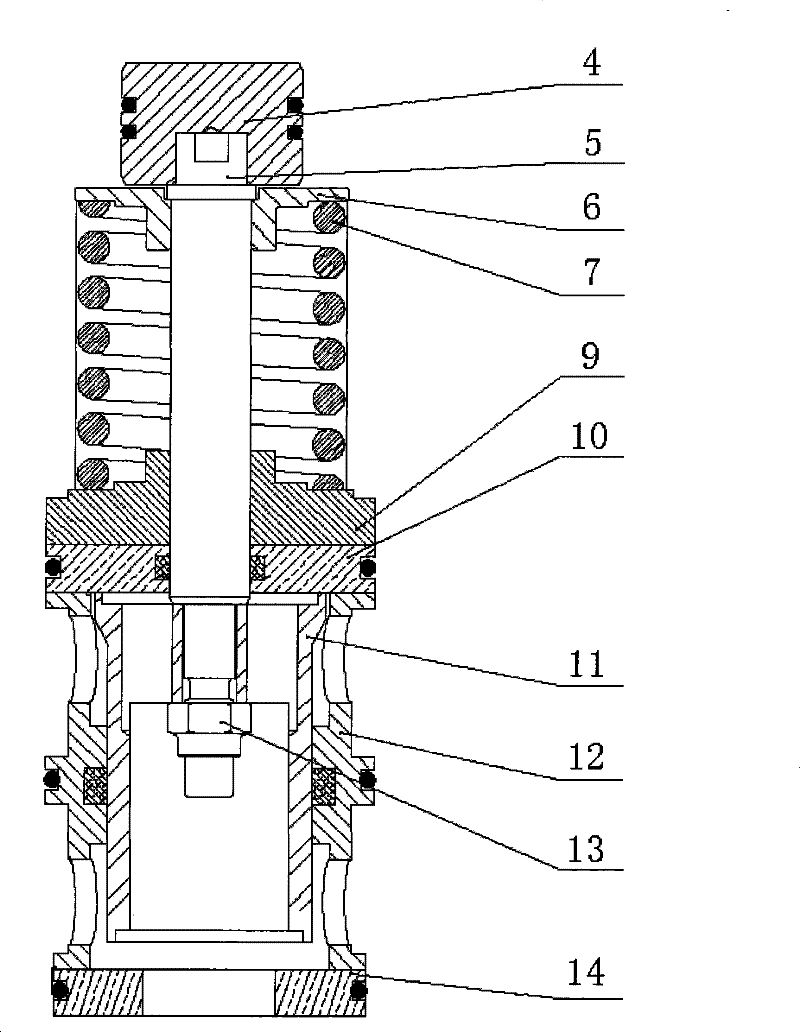

[0021] Embodiment 1: see figure 1 . The underwater hydraulic reversing valve is divided into two parts, namely the hydraulic pilot valve and the hydraulic control main valve. Pilot valve body 1 is made of high-strength seawater-resistant stainless steel. The hydraulic pilot valve is a two-position three-way valve; the hydraulic control main valve is a seat valve. The hydraulic control valve consists of pilot valve body 1, plug 2, electromagnetic control module 3, piston 4, piston rod 5, spring support plate 6, compression spring 7, main valve seat 8, pressure plate 9, upper sealing plate 10, valve The core 11, the valve cover 12, the fixing nut 13 and the lower sealing plate 14 are composed.

[0022] There are three chambers on the pilot valve body 1, which are the electromagnetic control module installation chamber, the piston chamber and the spring chamber in turn. The three cavities are coaxial and located on the center line of the pilot valve body 1. The electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com