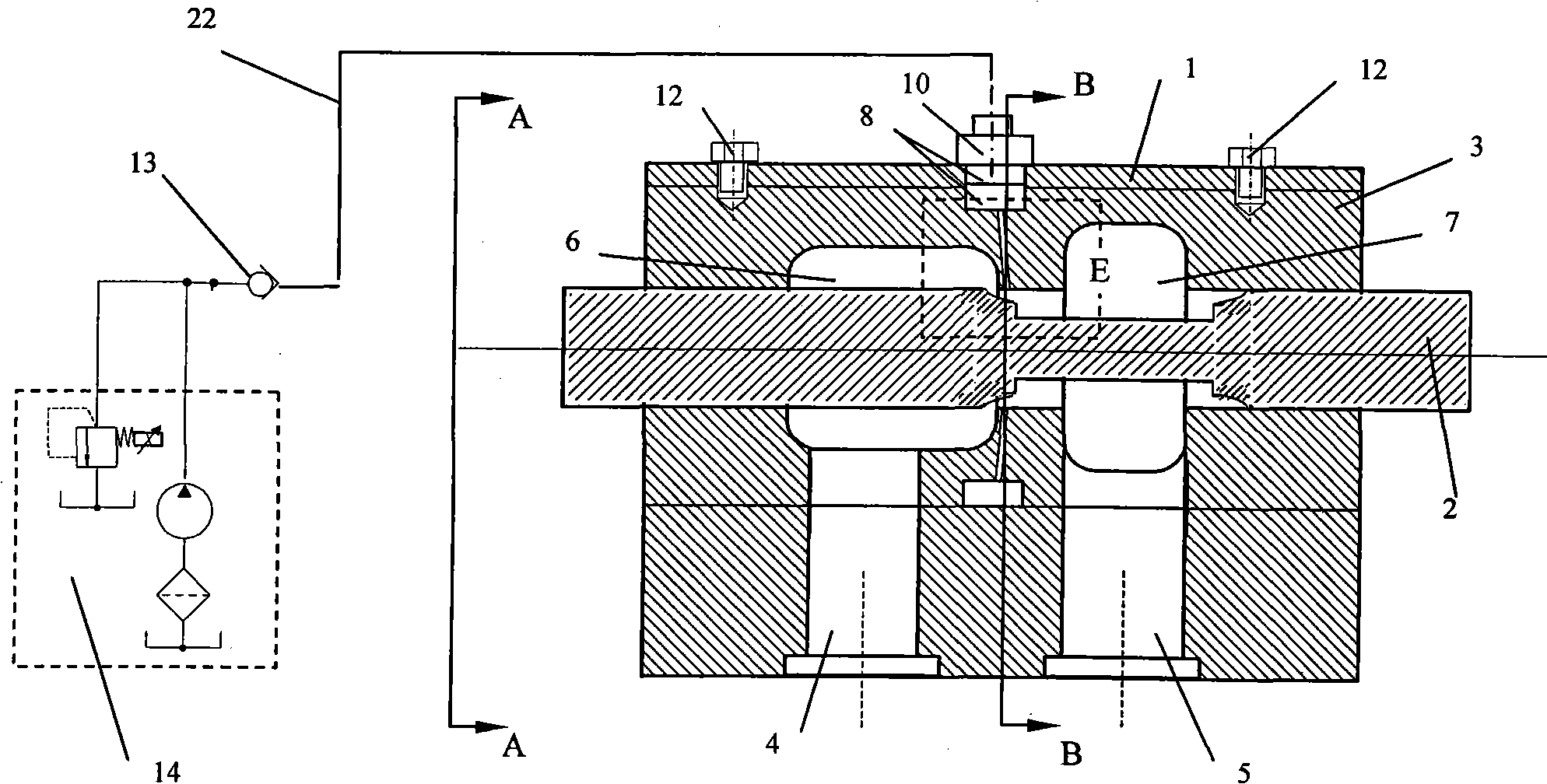

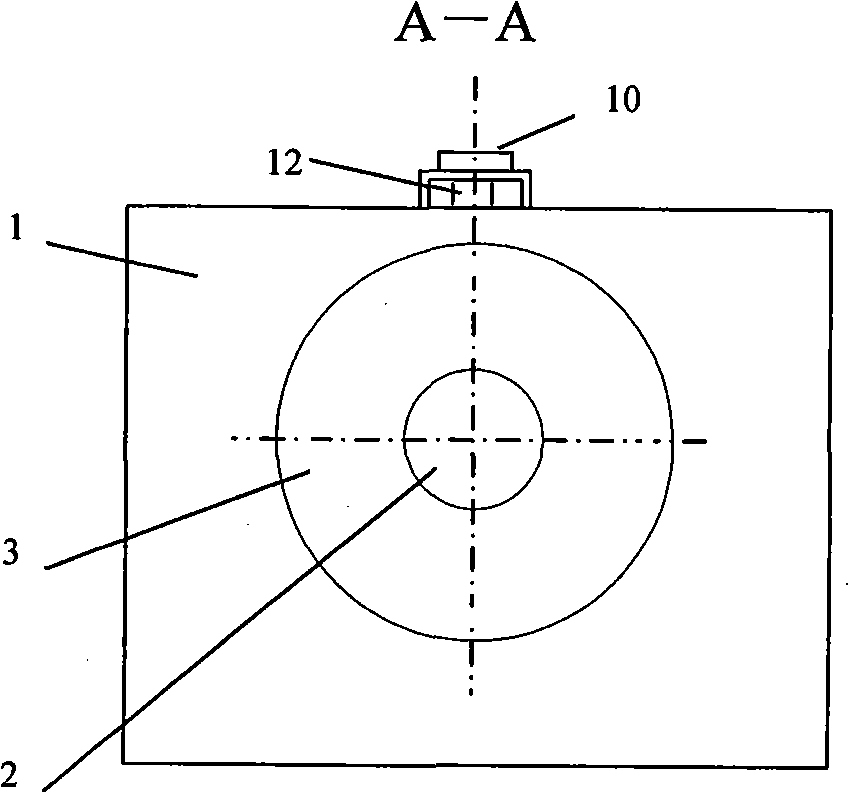

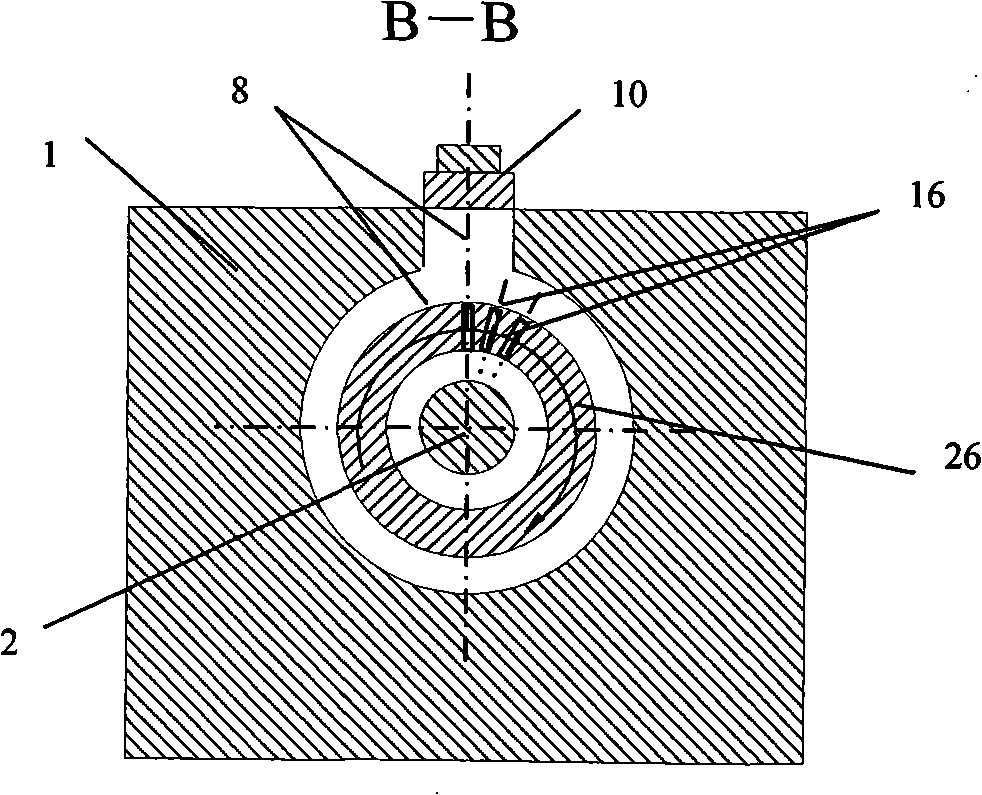

Pressure automatic filling type low noise throttling valve

A technology of automatic filling and throttling valve, applied in the direction of fluid pressure actuation device, lift valve, valve details, etc., can solve the problems of destroying flow and control characteristics, local pressure rise, poor suppression effect, etc., to improve noise Vibration and flow control characteristics, the effect of a single flow direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Noise and vibration are common phenomena in hydraulic systems, which have great harm to the stability and reliability of the system and the life of components. The high-frequency noise generated by cavitation is a major environmental pollution. It is difficult to completely eliminate the problems caused by cavitation with respect to the current throttle valve structure. On the basis of ensuring the operating characteristics of the hydraulic system, it is an urgent problem to suppress the generation of cavitation as much as possible. According to the known principles of cavitation inception and cavitation sound, when the partial pressure of the liquid is lower than the air separation pressure or saturated vapor pressure, the gas will be separated from the liquid to form bubbles or bubble flow, that is, cavitation. The cavitation develops and coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axis angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com