Hot pipe deposited horizontally

A technology of horizontal placement and heat pipes, applied in the field of heat pipes, can solve problems such as the decrease of the working efficiency of the heat pipes and the reduction of the effective heat exchange area of the heat pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

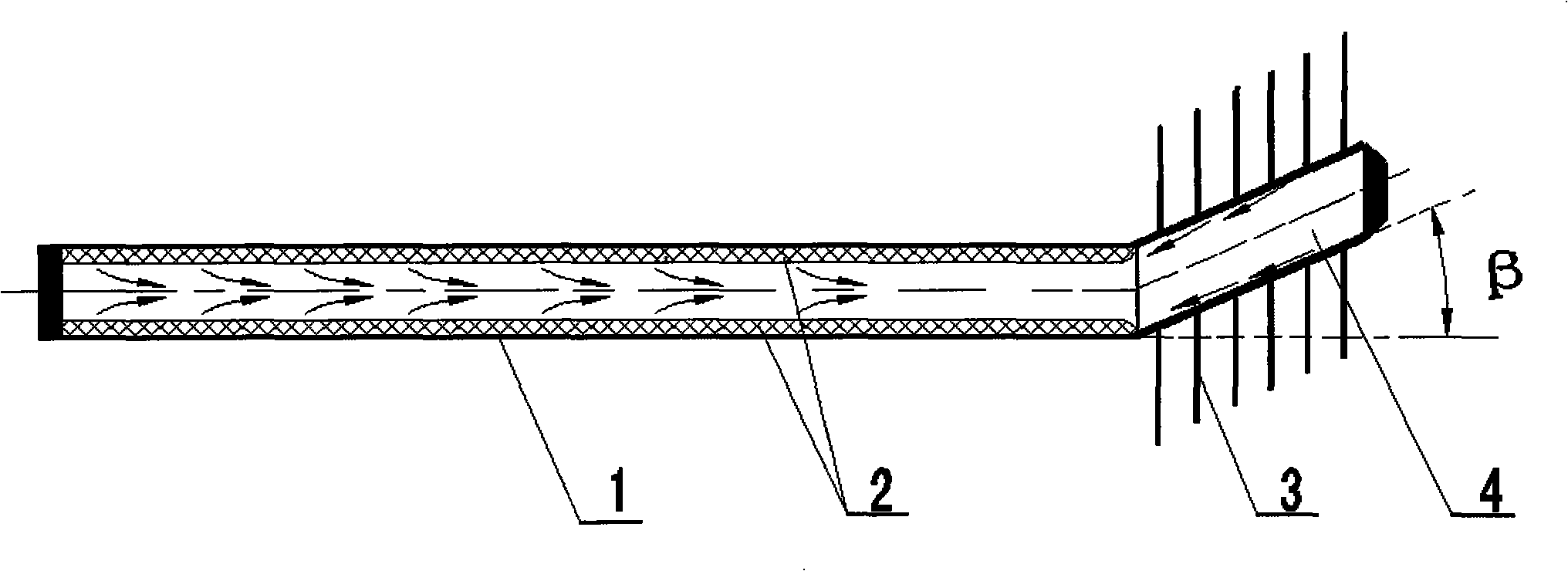

[0012] Embodiment 1: The heat pipe for horizontal placement includes a hollow pipe body with both ends closed and a working medium fluid 2 contained in the pipe body. In this embodiment, the material of the working medium is methanol. In addition, it can also be According to the use requirements of the heat pipe, materials such as ethanol, ethane, nitrogen or ammonia and other working fluid materials with phase change properties are used. The pipe body includes an evaporating section, an adiabatic section and a condensing section that communicate with each other. The adiabatic section is located between the evaporating section and the condensing section. The condensing section 4 forms an upward inclination angle β with respect to the evaporating and adiabatic section 1 . The outer circumference of the condensation section 4 is also provided with 1 to 20 annular cooling fins 3. The material of the cooling fins 3 is a metal sheet with good thermal conductivity. In this embodiment...

Embodiment 2

[0014] Embodiment 2: The upward inclination angle β of the condensation section is 5°-90°, which can be: 6°, 7°, 8°, 9°, 91°, 92°, 93°, 94° and other inclination angles. The mesh specification of the liquid-absorbing net is 100-145 mesh, which can be: 104 mesh, 144 mesh, etc. The wall thickness of the liquid-absorbing net is 0.10-0.45mm. Can be: 0.11mm, 0.12mm, 0.13mm, 0.14mm, 0.36mm, 0.37mm, 0.38mm, 0.39mm, etc. Among them, the angle of the inclination β, the mesh size of the liquid-absorbing net and the wall thickness of the liquid-absorbing net can all be matched with each other to form different combinations. Other structures of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0015] Embodiment 3: The upward inclination angle β of the condensation section is 10° to 45°, which can be: 11°, 12°, 13°, 14°, 31°, 32°, 33°, 34°, 35°, 36°, 37°, 38°, 39°, 40°, 41°, 42°, 43°, 44° and other inclination angles. The mesh size of the liquid-absorbing net is 105-140 mesh, which can be: 108 mesh, 136 mesh, etc. The wall thickness of the liquid-absorbing net is 0.15-0.40mm. Can be: 0.16mm, 0.77mm, 0.18mm, 0.19mm, 0.36mm, 0.37mm, 0.38mm, 0.39mm, etc. Among them, the angle of the inclination β, the mesh size of the liquid-absorbing net and the wall thickness of the liquid-absorbing net can all be matched with each other to form different combinations. Other structures of embodiment 3 are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com