Magnetic force driver

A transmission and magnetic technology, applied in the direction of electromechanical transmission, electric components, electrical components, etc., can solve the problems of inaccurate center sealing, vibration, etc., and achieve the effect of small volume, small motion inertia, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

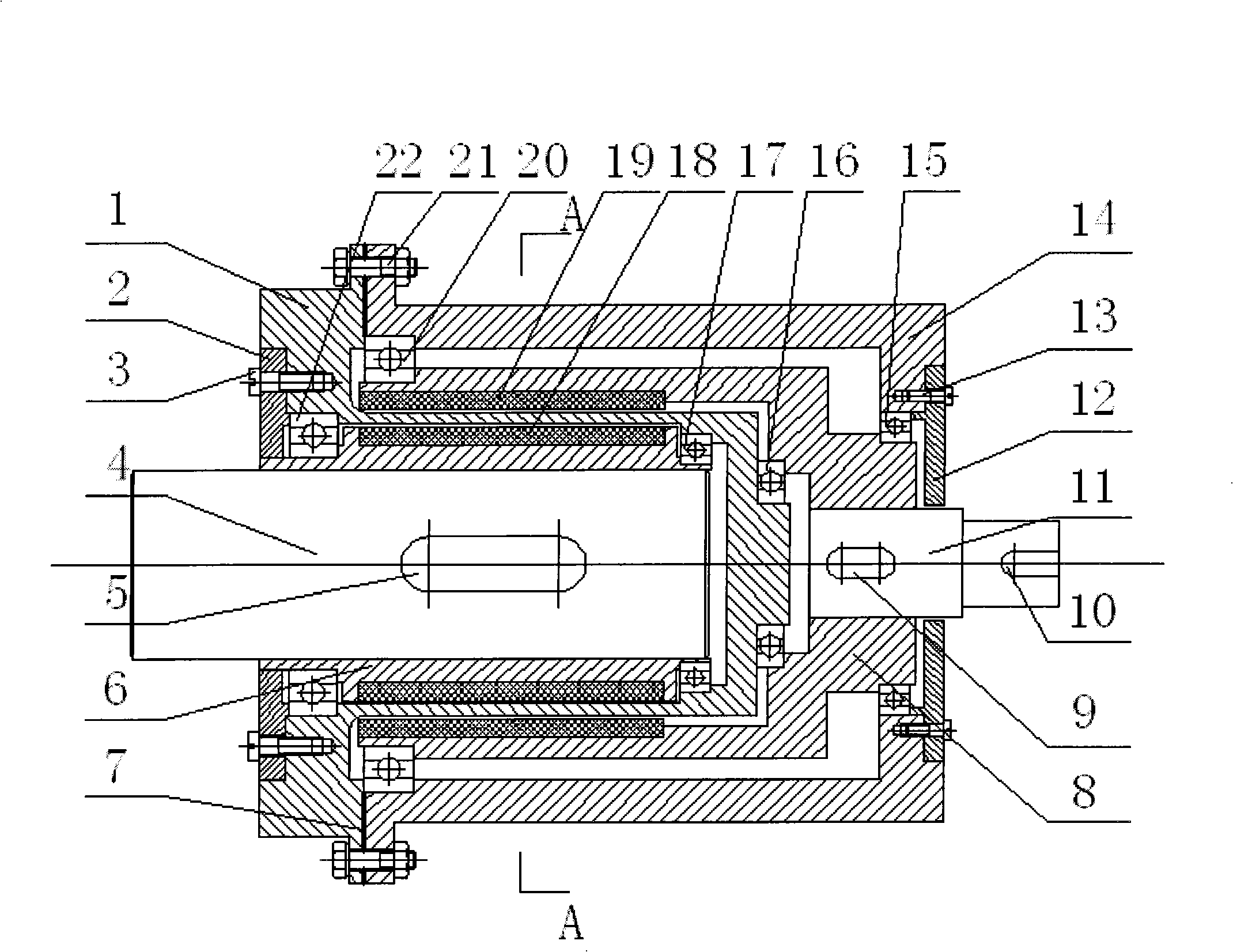

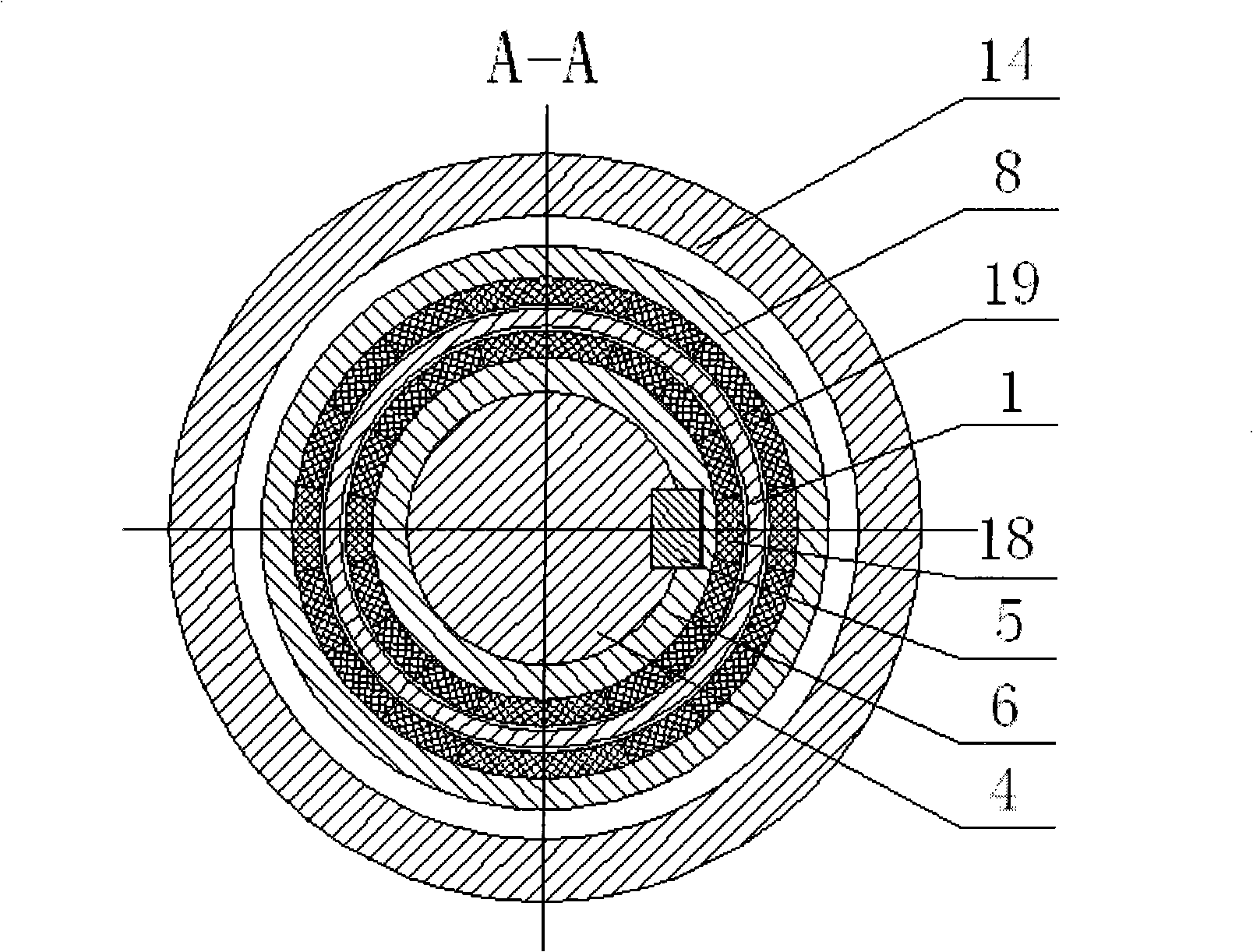

[0013] as attached figure 1 As shown, a magnetic actuator of the present invention includes four parts: a power input part, a power output part, a housing part and a magnetic circuit part. Under the support and positioning of the shell part, the original force is input through the power input part, the outer rotor 8 drives the outer permanent magnet 19 to rotate, the magnetic force line coupling of the magnetic circuit part drives the inner rotor 6 to rotate, and finally the obtained power is obtained through the power output part. Torque output to a vacuum environment. Here's how each movement works in detail:

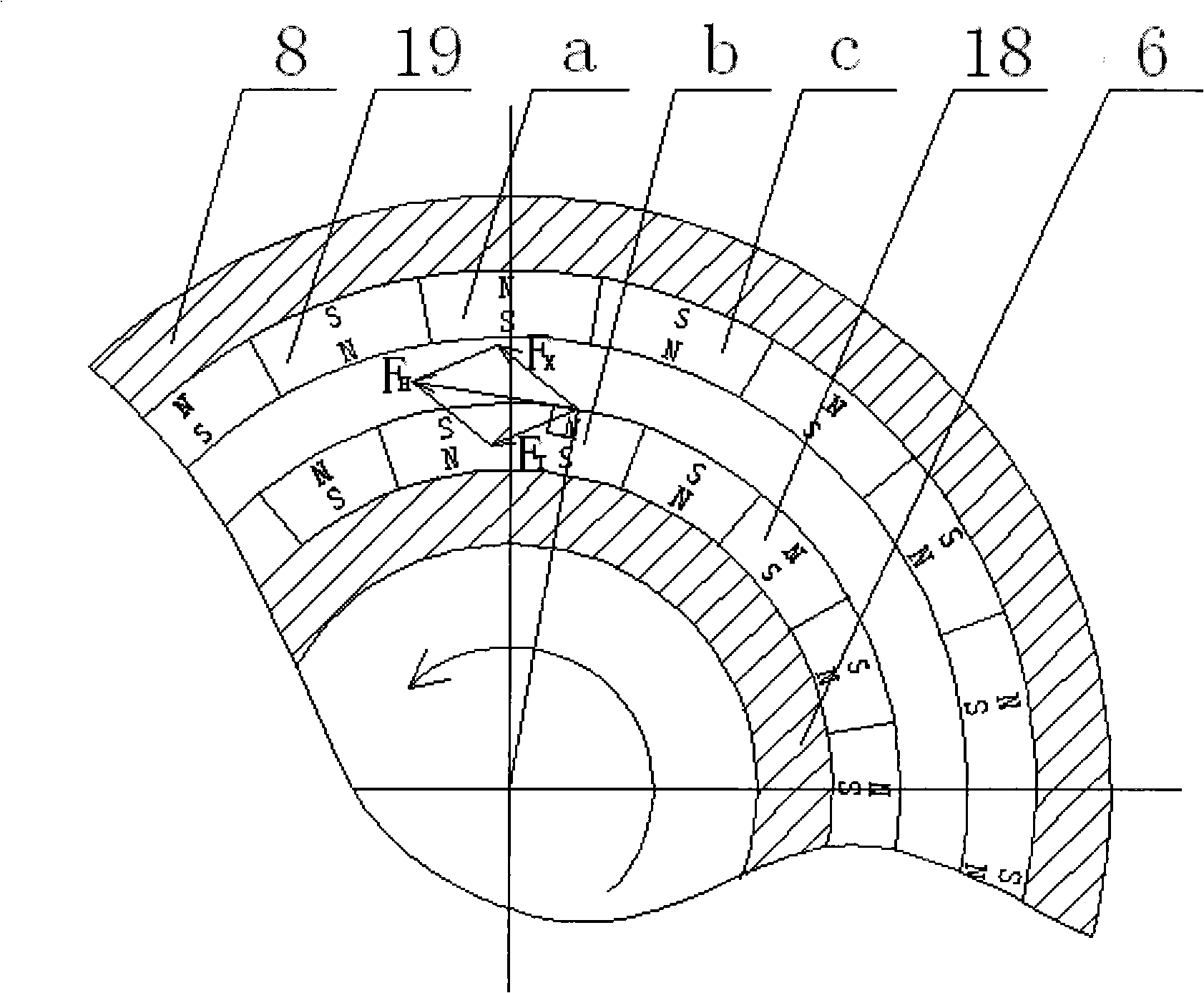

[0014] Start the motor, the torque output by the active motor is decelerated by the reduction gear to drive the input shaft 11 to rotate through the end key 10, the input shaft 11 drives the outer rotor 8 to start rotating through the connection of the key 9, and the outer permanent magnet 19 rotates synchronously thereupon. Take a pair of the first magnet a and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com