Method and apparatus for cooling air by three-stage vapour cooling

A technology for air cooling and air cooling, which is applied in heating methods, air conditioning systems, space heating and ventilation, etc., and can solve problems such as open places that cannot be used, retrofits, and increased water pump power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

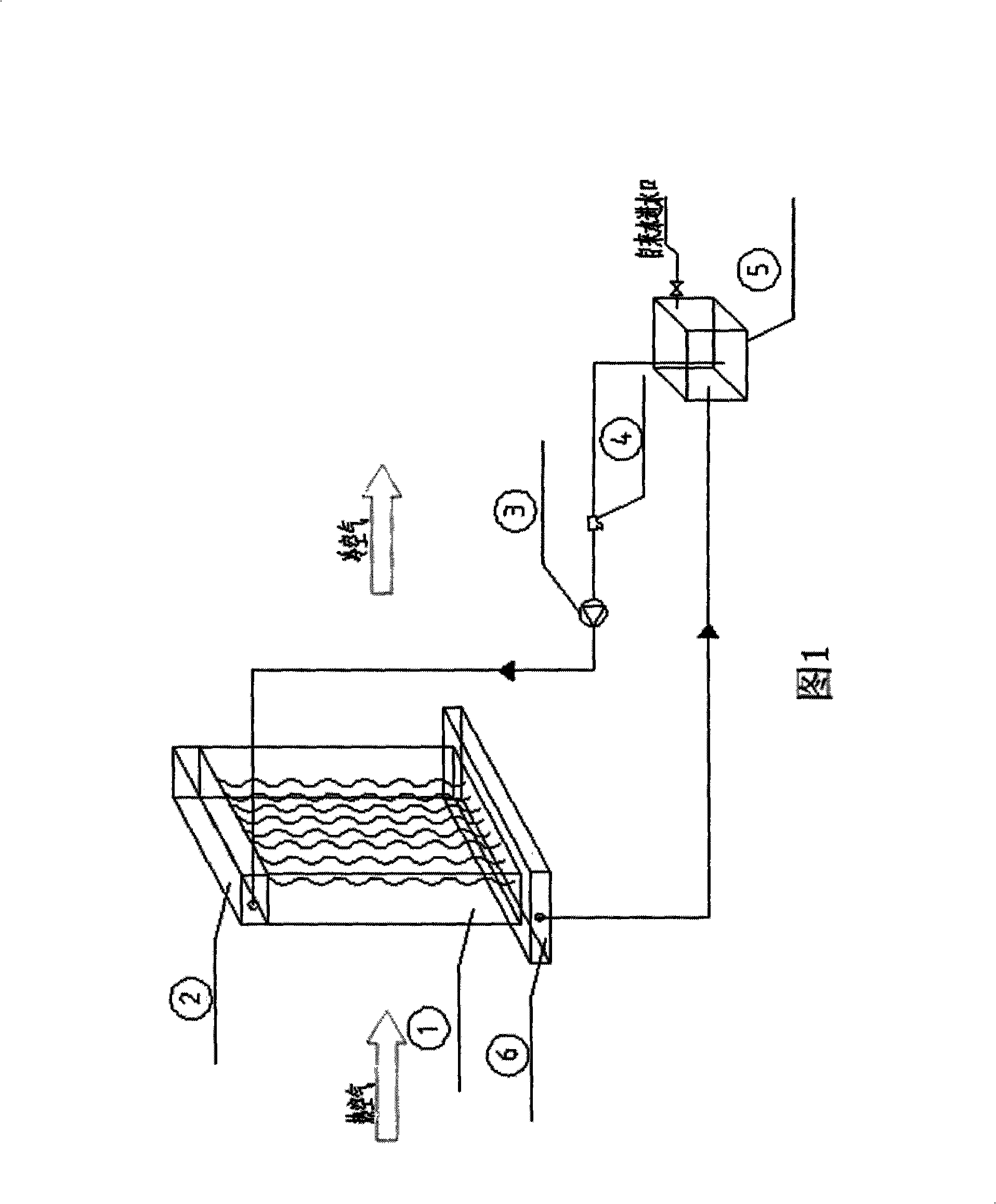

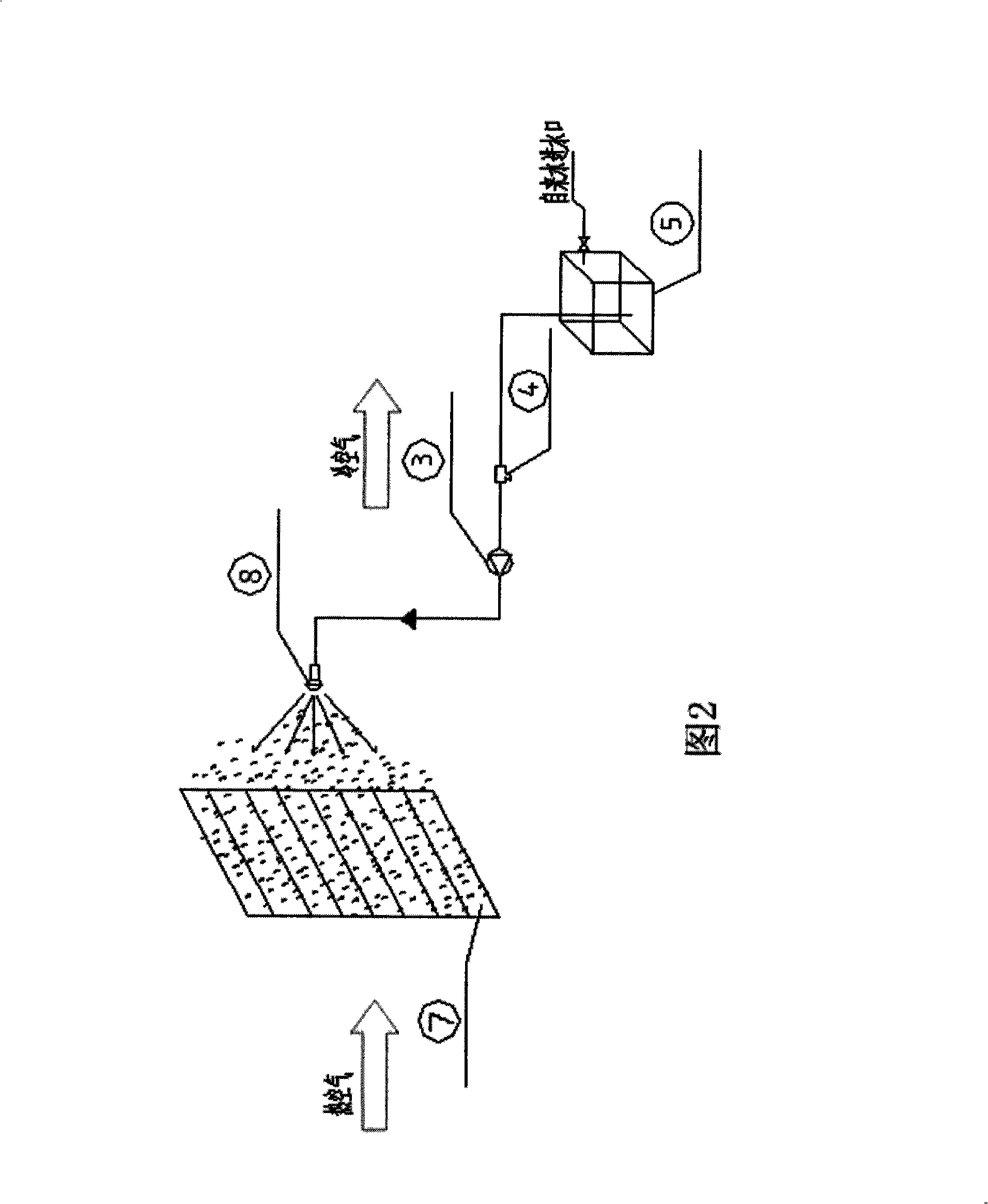

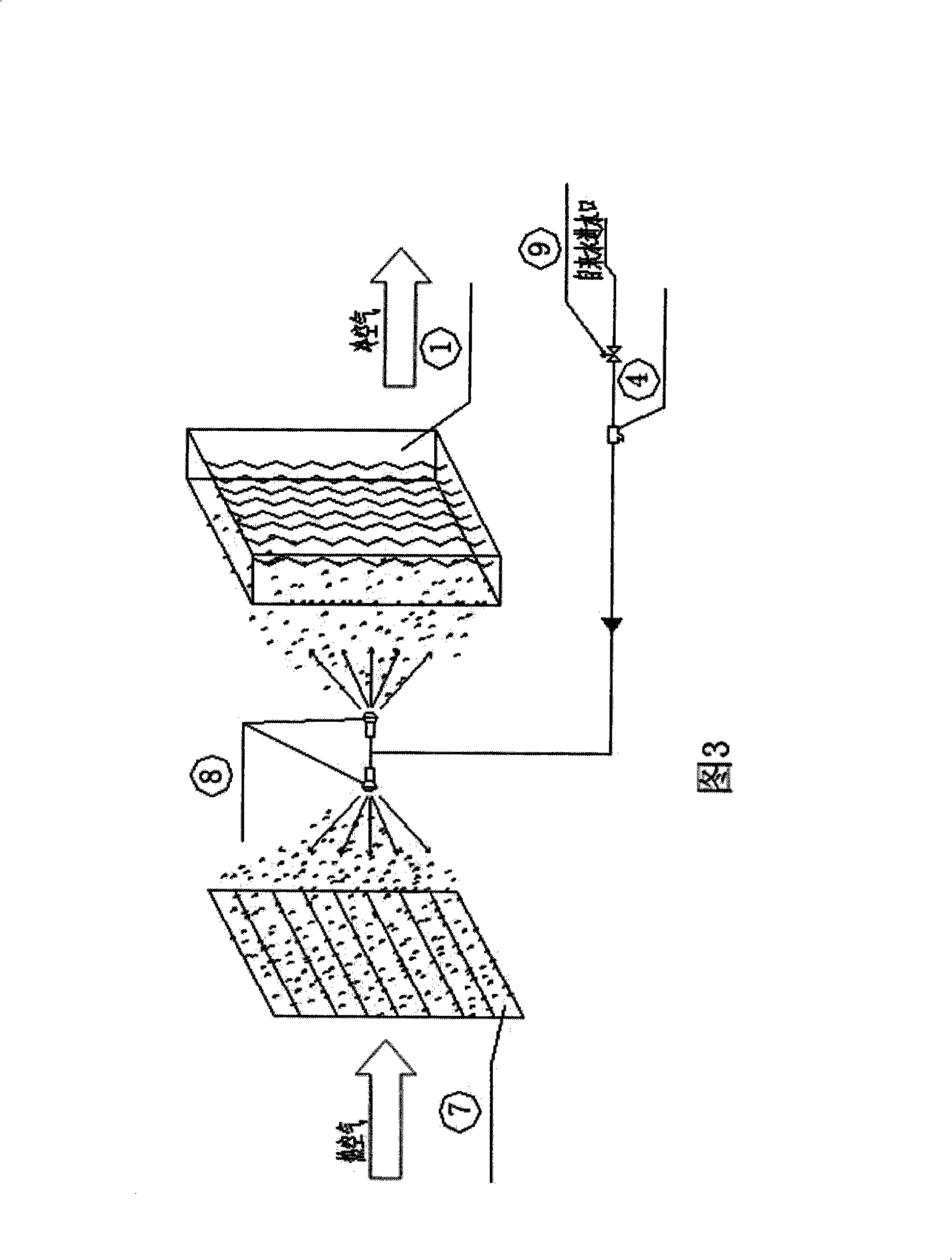

[0042] Technical scheme of the present invention is as follows:

[0043] The present invention can be used as an independent air cooling device; at the same time, it can also be used as an additional device for outdoor air-cooled condensers of various air-cooled air-conditioning equipment and refrigeration equipment. . Fig. 3 is a schematic diagram of the three-stage evaporative cooling air cooler of the present invention.

[0044]The air entering the device passes through the mesh (plastic, nylon, metal) packing, the water mist area, and finally the wet curtain (inorganic, organic, metal) packing in sequence. During this process, the air dry bulb temperature decreases. The cooled air enters the refrigeration and air conditioning equipment to absorb heat and discharge it to the atmosphere.

[0045] When the outside air passes through the mesh filler 7, due to the water spray from the spray head 8, water in the gaps of the mesh filler 7 contacts the air flowing through, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com