Assistance processing method for printed circuit board

A printed circuit board and auxiliary processing technology, which is applied to the formation of electrical connection of printed elements and the formation of conductive patterns, etc., can solve the problems of easy breakage and open circuit of ink, increased ink loss, and exposed copper, so as to save material cost investment and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preferred embodiment of an auxiliary processing method for a printed circuit board of the present invention, the steps of which include:

[0033] (1) Cutting, making the base material of the circuit board to be processed into a processing size;

[0034] (2) Drilling, setting up positioning holes on the base material of the circuit board to be processed;

[0035] (3) Cleaning, washing the processed circuit board base material with water, and then drying;

[0036] (4) to be printed;

[0037] (5) Paste a layer of medium on the back of the printed surface of the circuit board substrate to be processed;

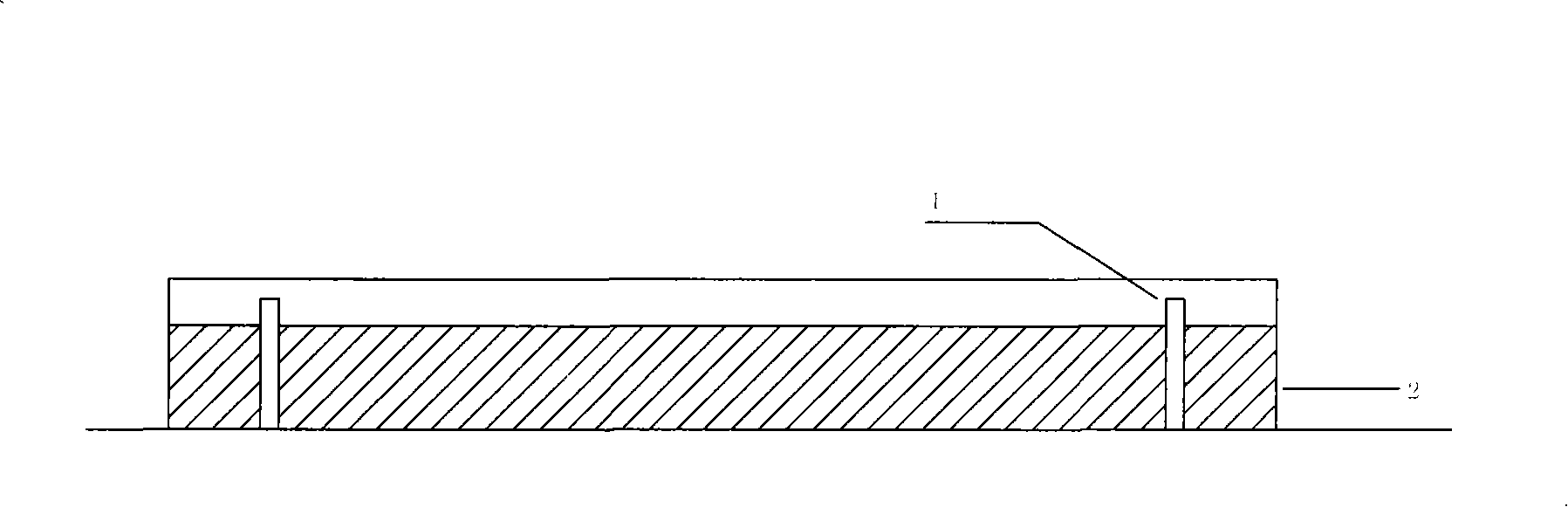

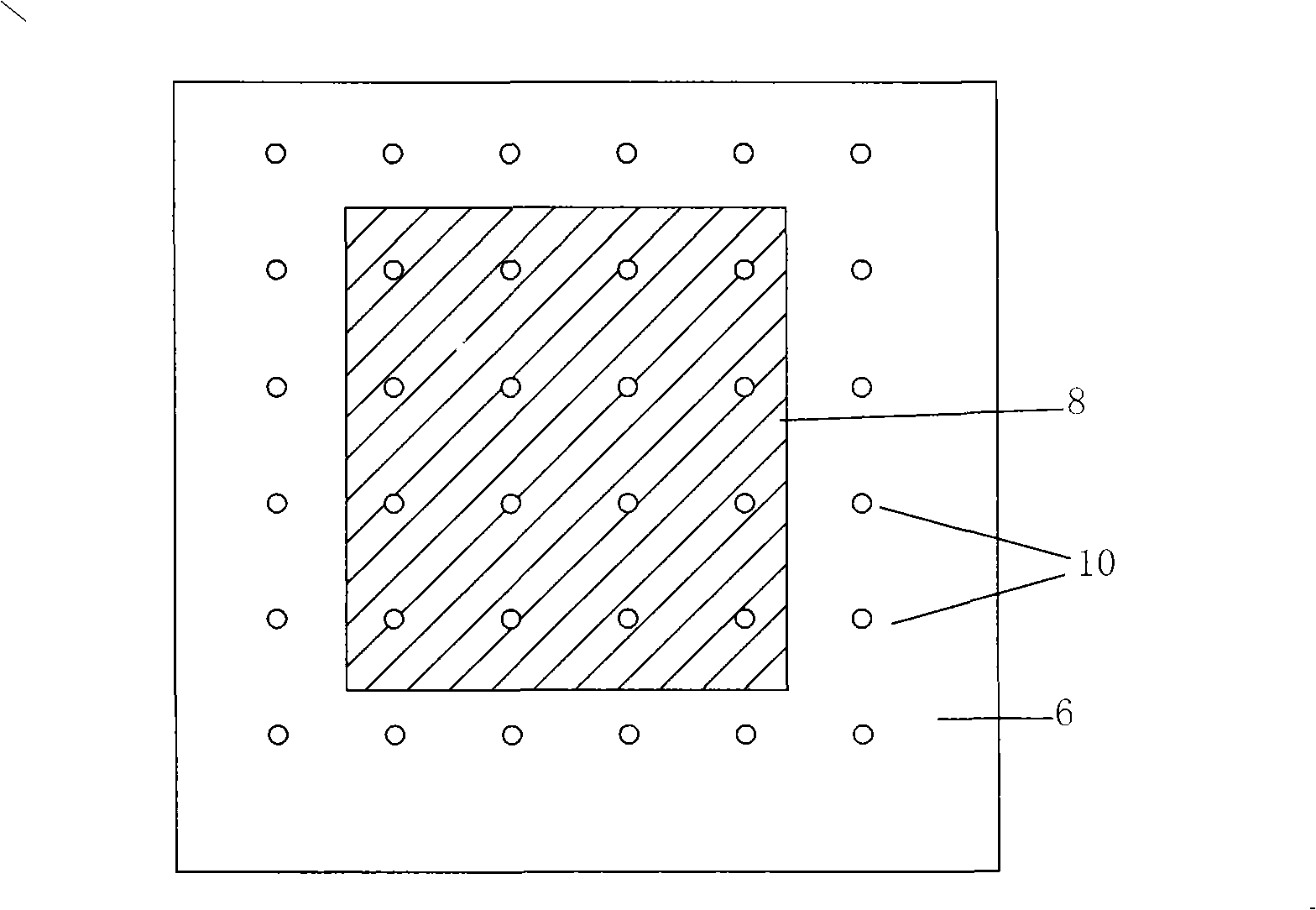

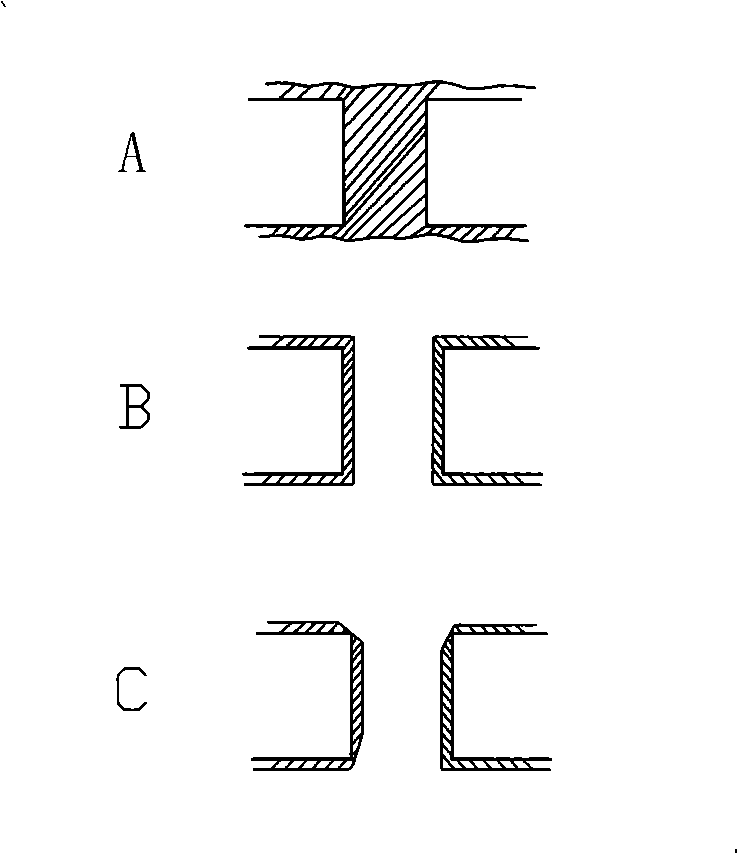

[0038] The medium used in the step (5) is newsprint; the step (5) includes the following steps: ① cutting the medium into the processing size; ② drilling holes in the medium; ③ using the drilled medium as a liner Material pads on the printing table, such as Figure 4 In the step of the drilling shown in the figure: the medium is drilled to form an avoidance hole 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com