Processing technique of annular thin wall part

A technology for processing thin-walled parts and thin-walled parts, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low pass rate of workpiece processing, elastic deformation of parts, and inability to meet processing accuracy, etc. Process reliability, effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

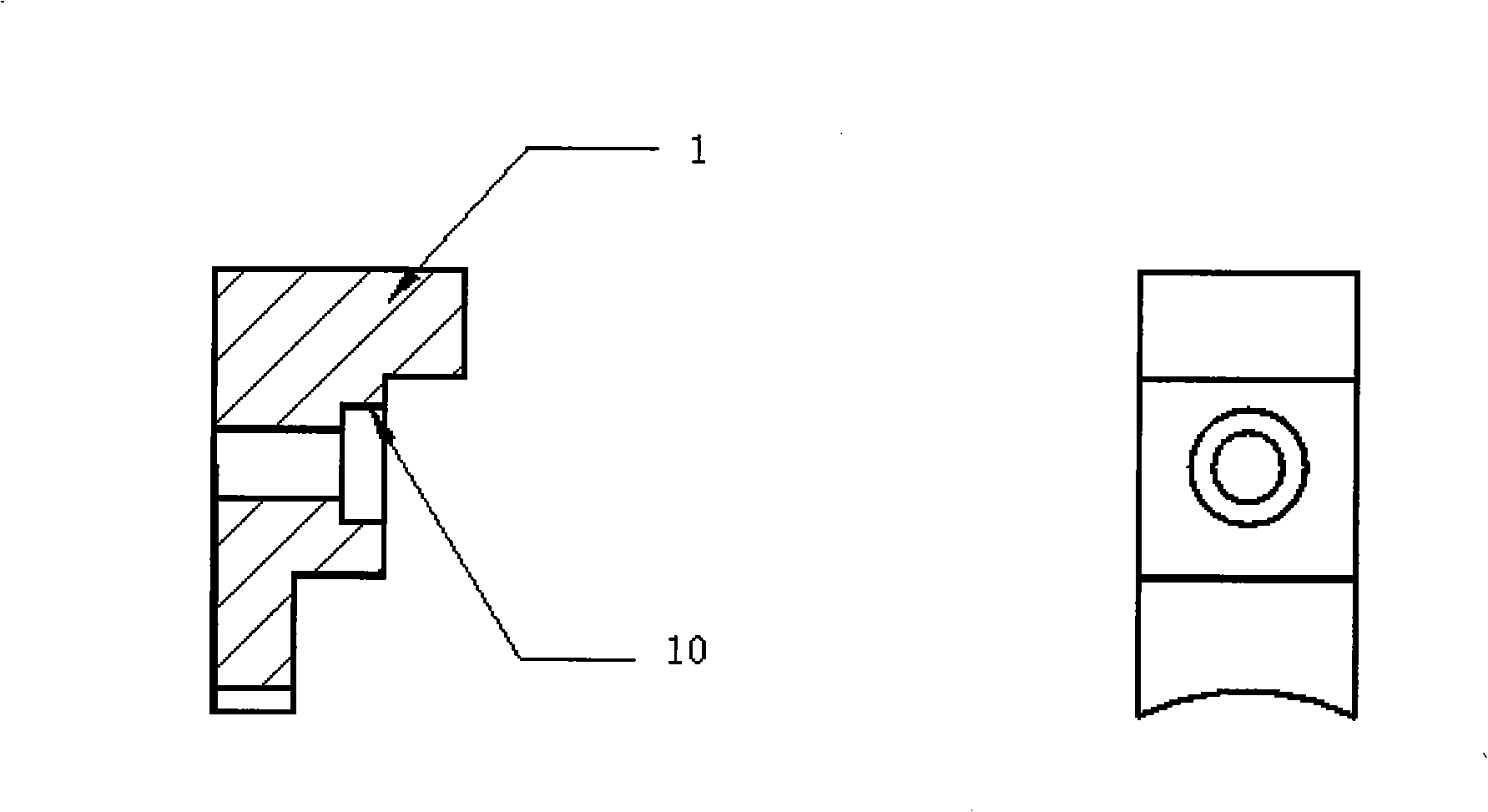

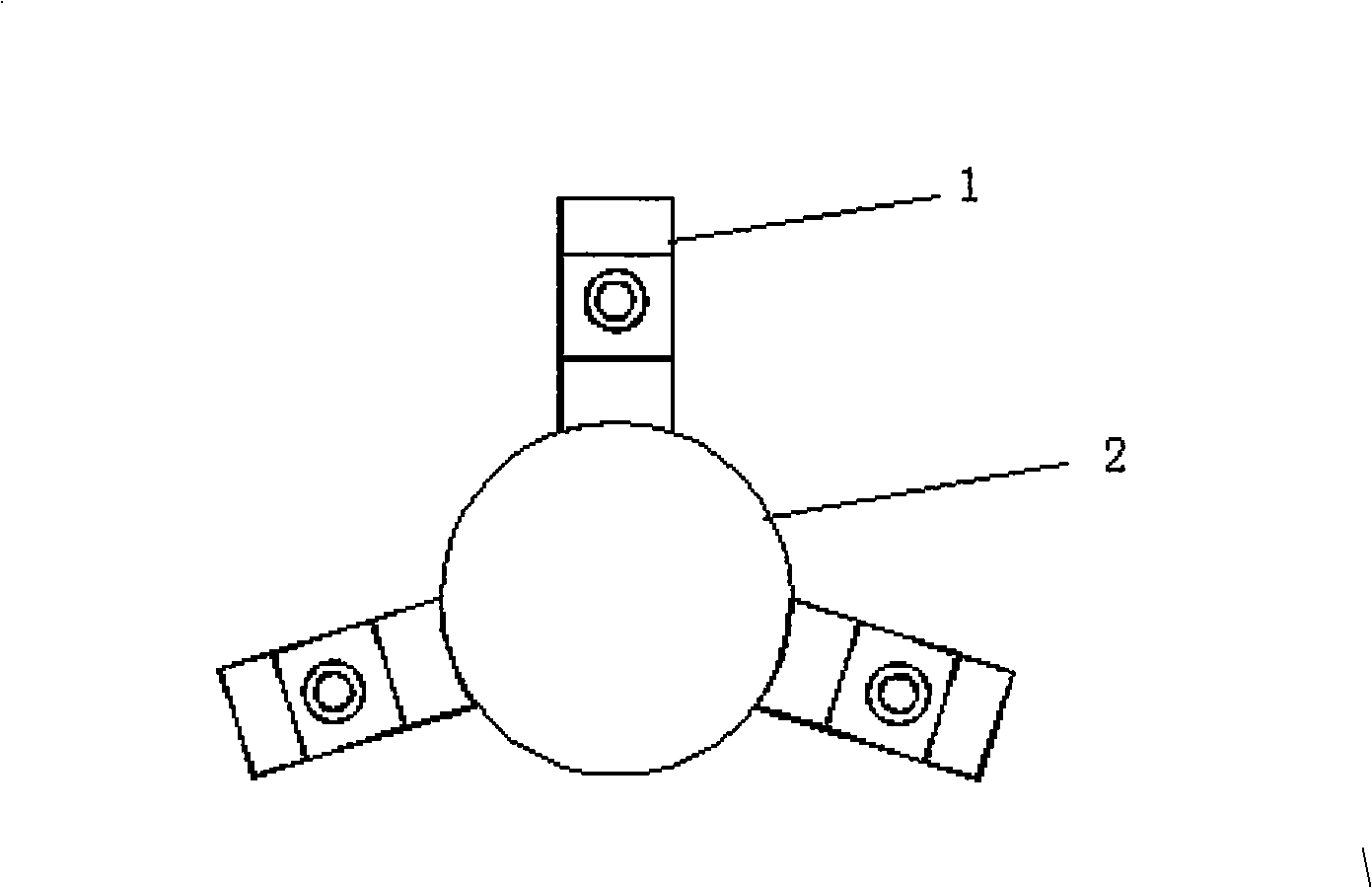

[0042] Embodiment 1. The making of soft three claws 1

[0043] Material:

[0044] The soft three-claw material is ordinary aluminum, LY12. This material is lightweight and cheap. When turning, it is not easy to "eat the knife" to wear the cutting edge. Especially in high-speed cutting and small feed rate, it is easier to obtain a smooth surface, and it is an ideal tooling material.

[0045] The principle and production of soft three claws:

[0046] Since the clamping surface of the jaws of the ordinary three-jaw chuck is not the same surface, the workpiece cannot be guaranteed to be in the same central position during the two clamping processes. Therefore, if the workpiece is directly clamped on the three-jaw chuck of the lathe, it will inevitably affect its coaxiality.

[0047] The soft three-jaw is fixed on the three-jaw chuck by screws. The center hole (for clamping the mandrel) is machined by the lathe. In this way, after the workpiece is put on the mandrel, the acc...

Embodiment 2

[0049] Embodiment 2. Annular thin-walled sleeve processing

[0050] Annular thin-walled sleeve such as image 3 , Figure 4 Shown:

[0051] Material: 1Cr18Ni9Ti;

[0052] Outer diameter: Φ72mm;

[0053] Inner diameter: Φ68.6(+0.02 / 0)mm;

[0054] Workpiece width 8mm;

[0055]The ratio of outer diameter to wall thickness is 72 / 1.7=42.35;

[0056] Coaxiality 0.05mm.

[0057] Processing steps:

[0058] 1. Outer diameter of the upper mandrel

[0059] The direct positioning of the workpiece is changed, and the positioning of the workpiece through the tooling does not cause the workpiece to be clamped and deformed. Therefore, the design and production of tooling is very critical.

[0060] Tooling material: brass (H62) for the mandrel, mandrel sleeve, outer cover and locking cover. Due to the low hardness of this material, the friction coefficient is also small, and it has self-lubricating properties especially in high-speed machining (that is, no need Adding cutting fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com