Conductive cement and method for preparing same

A technology of conductive cement and cement, applied in the field of building materials industry, can solve the problems of unstable conductive performance, affecting the performance of conductive cement and its products, and low strength of conductive cement and its products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

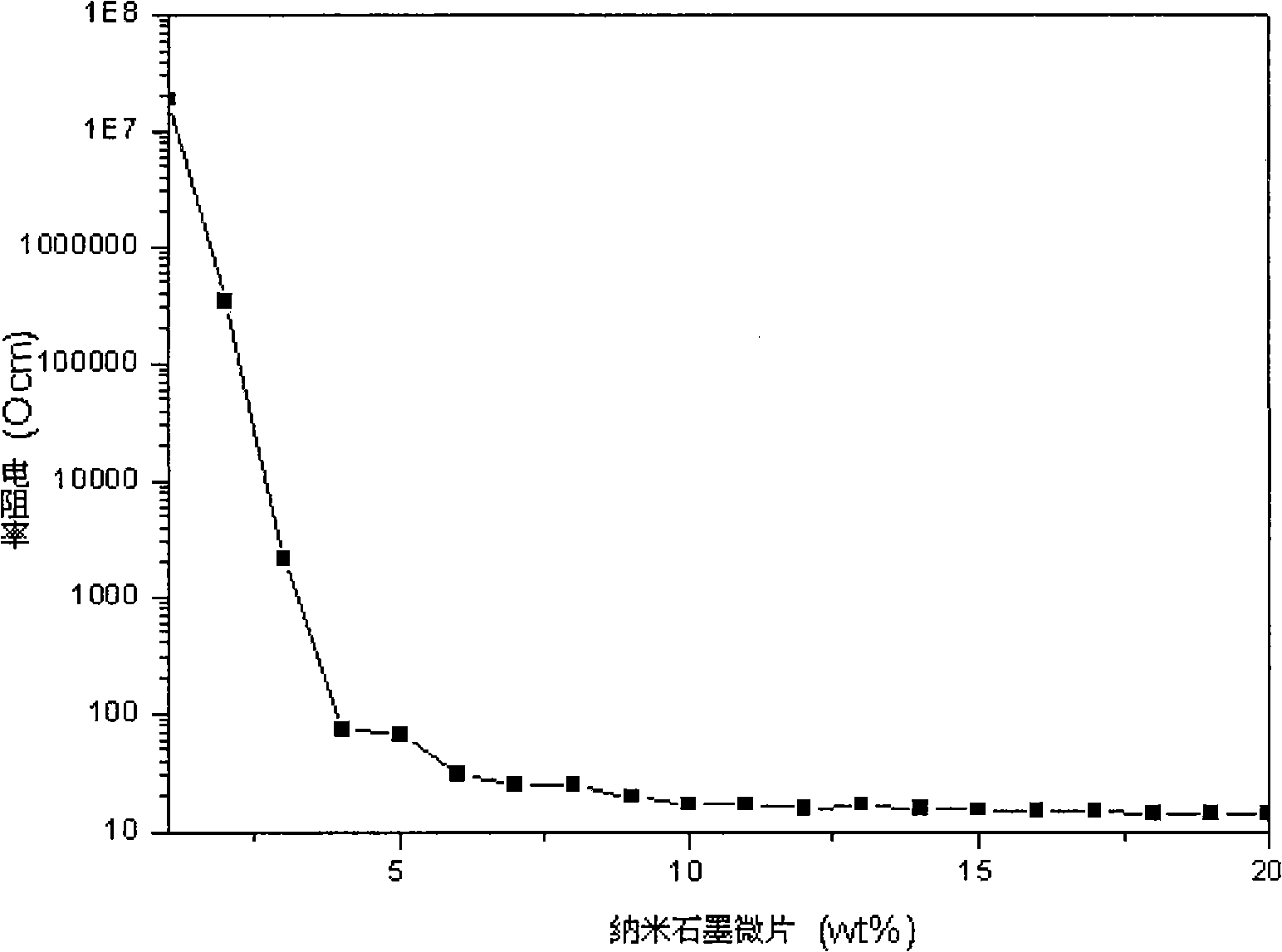

[0034] The conductive cement of the present invention is composed of the following components by weight: 100 parts by weight of cement, 50 parts by weight of sand, 3 parts by weight of nanographite microflakes, 50 parts by weight of water and 1.5 parts by weight of water reducer.

[0035] A kind of preparation method of conductive cement of the present invention is realized by following scheme:

[0036] (1) Take by weighing 100 parts by weight of cement, 50 parts by weight of sand, and 3 parts by weight of nanographite microflakes;

[0037] (2) Mix cement, sand and nanographite microflakes evenly, add 50 parts by weight of water and 1.5 parts by weight of water reducing agent, and stir for 3 minutes;

[0038] (3) Injection molding;

[0039] (4) Condensate at room temperature and 90% humidity for 24 hours, and test its various properties.

Embodiment 2

[0041] The conductive cement of the present invention is composed of the following components by weight: 100 parts by weight of cement, 100 parts by weight of sand, 8 parts by weight of nanographite microflakes, 65 parts by weight of water and 1.5 parts by weight of water reducer.

[0042] A kind of preparation method of conductive cement of the present invention is realized by following scheme:

[0043] (1) Take by weighing 100 parts by weight of cement, 100 parts by weight of sand, and 8 parts by weight of nanographite microflakes;

[0044] (2) Mix cement, sand and nanographite microflakes evenly, add 65 parts by weight of water and 1.5 parts by weight of water reducing agent, and stir for 3 minutes;

[0045] (3) Injection molding;

[0046] (4) Condensate at room temperature and 90% humidity for 24 hours, and test its various properties.

Embodiment 3

[0048] The conductive cement of the present invention is composed of the following components by weight: 100 parts by weight of cement, 150 parts by weight of sand, 15 parts by weight of nanographite microflakes, 80 parts by weight of water and 1.5 parts by weight of water reducer.

[0049] A kind of preparation method of conductive cement of the present invention is realized by following scheme:

[0050] (1) Take by weighing 100 parts by weight of cement, 150 parts by weight of sand, and 15 parts by weight of nanographite microflakes;

[0051] (2) Mix cement, sand and nano-graphite microflakes evenly, add 80 parts by weight of water and 1.5 parts by weight of water reducing agent, and stir for 3 minutes;

[0052] (3) Injection molding;

[0053] (4) Condensate at room temperature and 90% humidity for 24 hours, and test its various properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com