Reaction device for preparing low carbon olefin from methanol or dimethyl ether

A technology of low-carbon olefins and reaction devices, applied in the field of reaction devices, can solve the problems of low yield of low-carbon olefins, achieve the effects of improving selectivity, shortening residence time, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

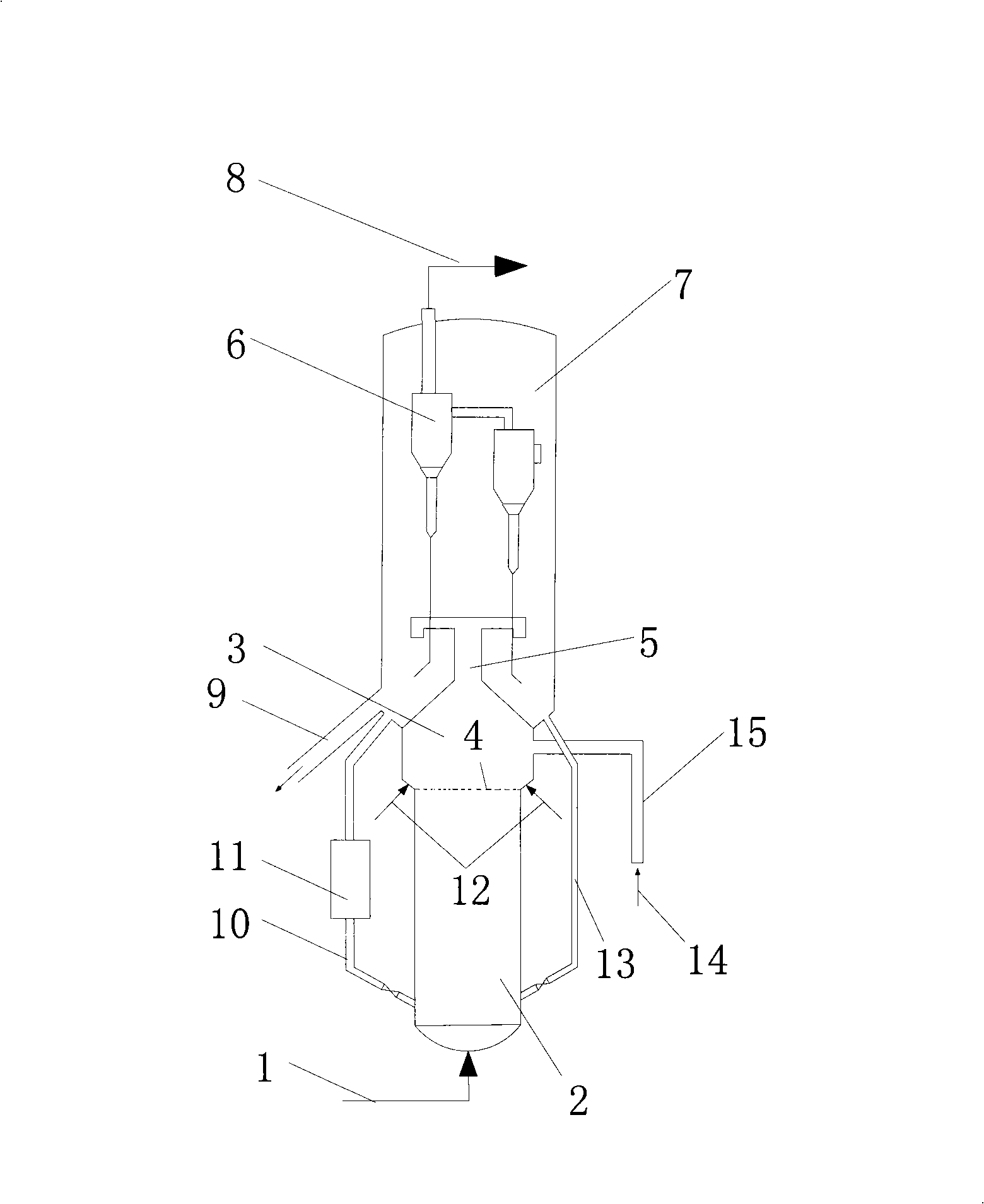

[0017] in such as figure 1 In the reaction device shown, the average temperature of the first reaction zone 2 is 470°C, the average temperature of the second reaction zone 3 is 530°C, the pressure at the top of the separation zone 7 of the reactor is 0.14MPa in gauge pressure, and the pure methanol feed , the feed is 2 kg / h, the superficial linear velocity of gas in the first reaction zone 2 is 1.1 m / s, the catalyst is modified SAPO-34, and the lifting medium of the regenerated catalyst circulation pipe 15 is unreacted methanol and dimethylformamide Ether, the heat exchange medium between the heat extractor 11 outside the reactor and the unborn catalyst is water vapor. The ratio of the diameter of the second reaction zone 3 and the first reaction zone 2 is 1.2: 1; the ratio of the diameter of the gas-solid rapid separation device 5 and the diameter of the second reaction zone 3 is 0.3: 1; The gas-solid cyclone separator 6 has two stages. The average catalyst carbon deposit i...

Embodiment 2

[0019] According to the conditions described in Example 1, the superficial linear velocity of gas in the first reaction zone 2 is 2.0 m / s, the ratio of the diameter of the second reaction zone 3 to the first reaction zone 2 is 2.0:1, and the gas-solid separation is rapid. The ratio of the diameter of the equipment 5 to the diameter of the second reaction zone 3 is 0.15:1, the lifting medium of the regenerated catalyst circulation pipe 15 is water vapor, and the yield of light olefins reaches 84.32% by weight.

Embodiment 3

[0021] According to the conditions described in Example 1, the hydrocarbons above C4 separated by the product separation section are divided into two parts, one part is used as the lifting medium of the regenerated catalyst circulation pipe 15, and the other part passes through the feedstock at the axial position of the second reaction zone 3. The mouth enters the second reaction zone, and the number of feed inlets is two, which is a counter-spray type, and the distance between the feed inlet position and the distribution plate 4 is 1 / 4 of the height of the second reaction zone 3 . Change the average temperature of the first reaction zone 2 to 500°C, the ratio of the diameter of the second reaction zone 3 to the first reaction zone 2 is 1.4:1; The ratio is 0.5:1; the gas-solid cyclone separator 6 in the separation zone 7 of the reactor has three stages, and the yield of light olefins reaches 88.43% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com