Pretreatment process for electrophoresis coating

An electrophoretic coating and pre-treatment technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., to achieve the effect of smaller investment, shorter process, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

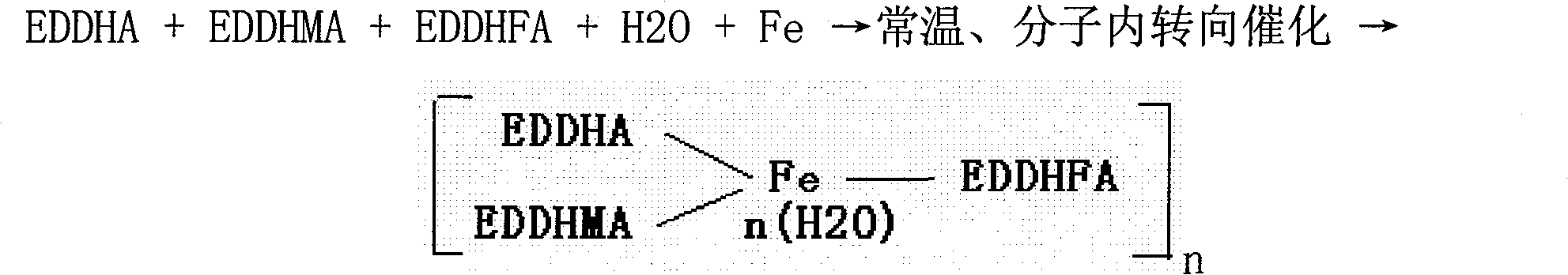

Image

Examples

Embodiment 1

[0046]Embodiment 1, the pretreatment process of electrophoretic coating, comprises the following steps: first put the workpiece to be treated in a high-pressure water washing tank for high-pressure water washing; during high-pressure water washing, the temperature of the tank liquid is 35 ° C, and the washing time is 3′05″, free The alkalinity is 5 points, and the spray pressure is 0.35MP. Put the workpiece after washing with water into the degreasing tank for degreasing. During the degreasing process, the temperature of the tank solution is 50°C, the degreasing time is 2′48″, and the free alkalinity At 8:00, put the workpiece after degreasing into the clear water tank for washing. The time for washing is 50″. Put the workpiece after washing into the pickling tank for pickling treatment. , the bath temperature is 55°C, the pickling time is 2'38", and the total acid point is 550 points. Put the workpiece after pickling into the clear water tank for water washing, and the time fo...

Embodiment 2

[0057] Embodiment 2, the pretreatment process of electrophoretic coating, comprises the following steps: first put the workpiece to be treated into a high-pressure water washing tank for high-pressure water washing; during high-pressure water washing, the bath temperature is 40°C, and the washing time is 3′20″, free The alkalinity is 5.5 points, the spray pressure is 0.38MP, and the workpiece after washing is put into the degreasing tank for degreasing. During the degreasing process, the temperature of the tank solution is 55°C, the degreasing time is 3′, and the free alkalinity is 11 point, put the workpiece after degreasing into the clear water tank for water washing, the time for washing is 1′, put the workpiece after water washing into the pickling tank for pickling treatment, during pickling, the tank The liquid temperature is 60°C, the pickling time is 2′50″, and the total acid point is 600 points. Put the workpiece after pickling into the clear water tank for water washi...

Embodiment 3

[0069] Embodiment 3, the pretreatment process of electrophoretic coating, comprises the following steps: first put the workpiece to be treated in a high-pressure water washing tank for high-pressure water washing; during high-pressure water washing, the bath temperature is 45°C, and the washing time is 3′35″, free The alkalinity is 6 points, and the spray pressure is 0.4MP. Put the workpiece after washing with water into the degreasing tank for degreasing. During the degreasing process, the temperature of the tank solution is 60°C, the degreasing time is 3′12″, and the free alkalinity At 14:00, put the workpiece after degreasing into the clear water tank for washing. The washing time is 1′10″. Put the workpiece after washing into the pickling tank for pickling treatment. When washing, the bath temperature is 65°C, the pickling time is 3′2″, and the total acid point is 650 points. Put the workpiece after pickling into the clear water tank for washing, and the washing time is 1′ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com