Gradient type temperature field heating element

A heating element and temperature field technology, applied in electric furnace heating, crystal growth, furnace type, etc., can solve the problems of affecting the stability of the temperature field, increasing the cost of equipment and the difficulty of control, and simplifying operation, maintaining stability, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

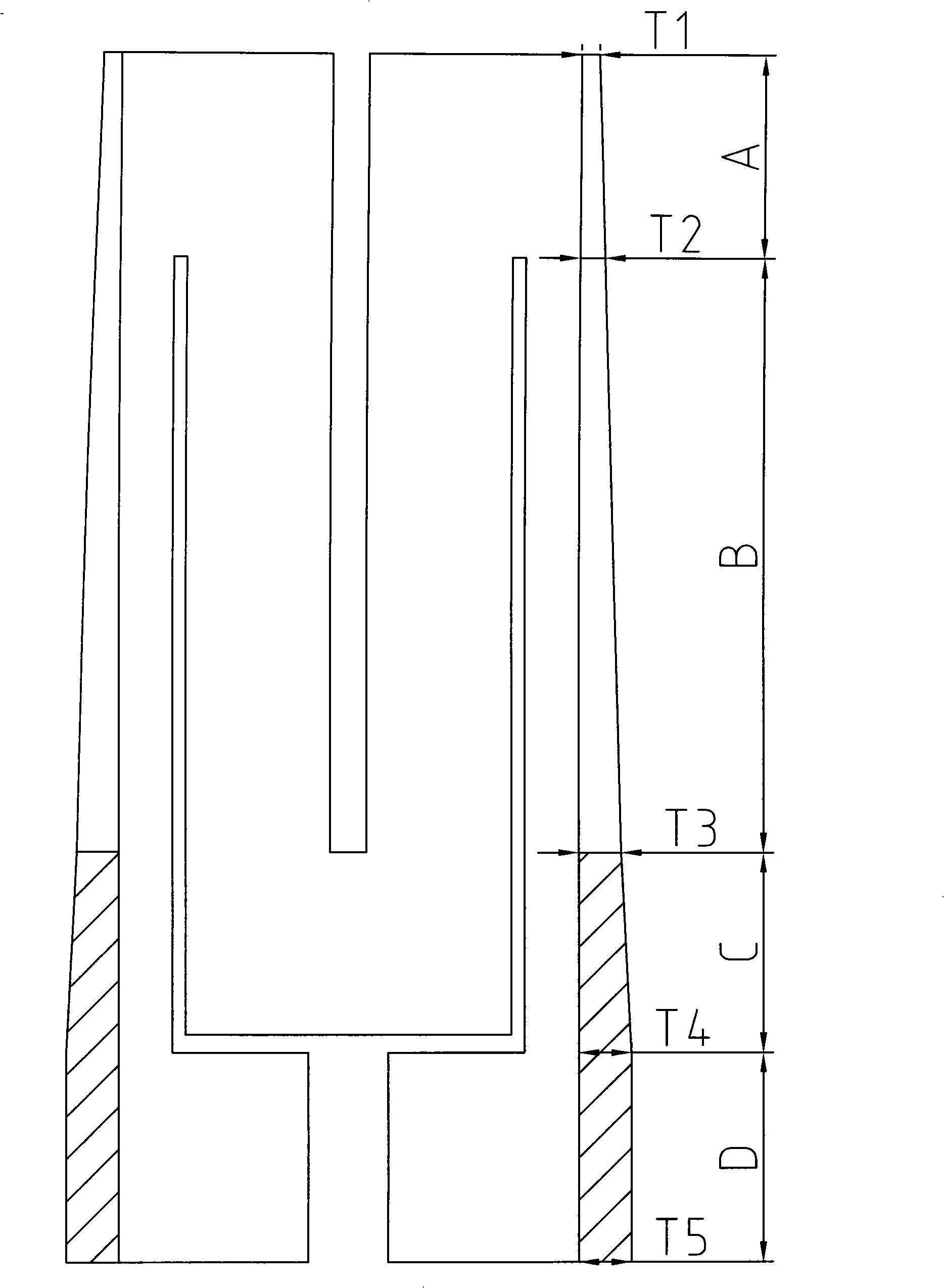

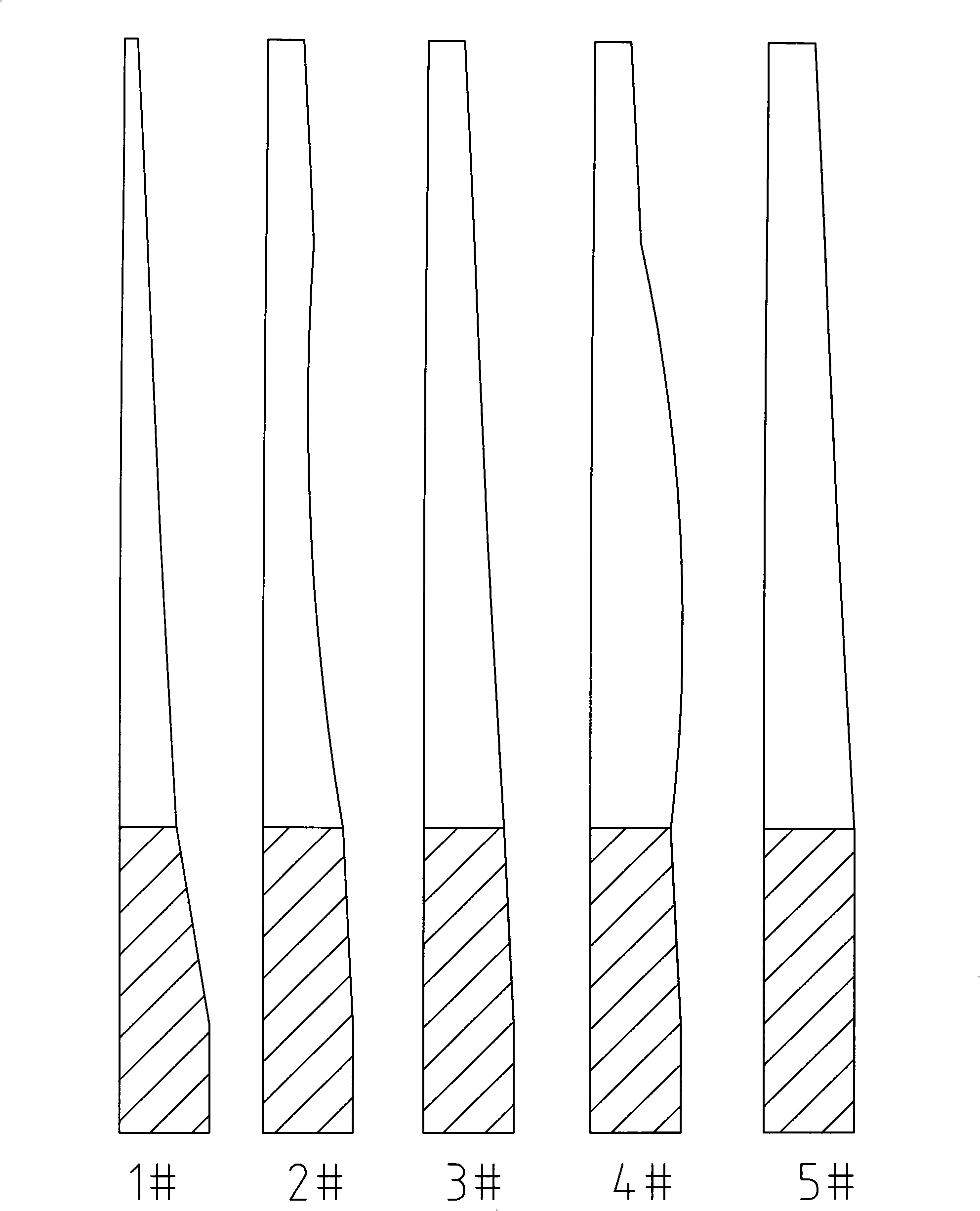

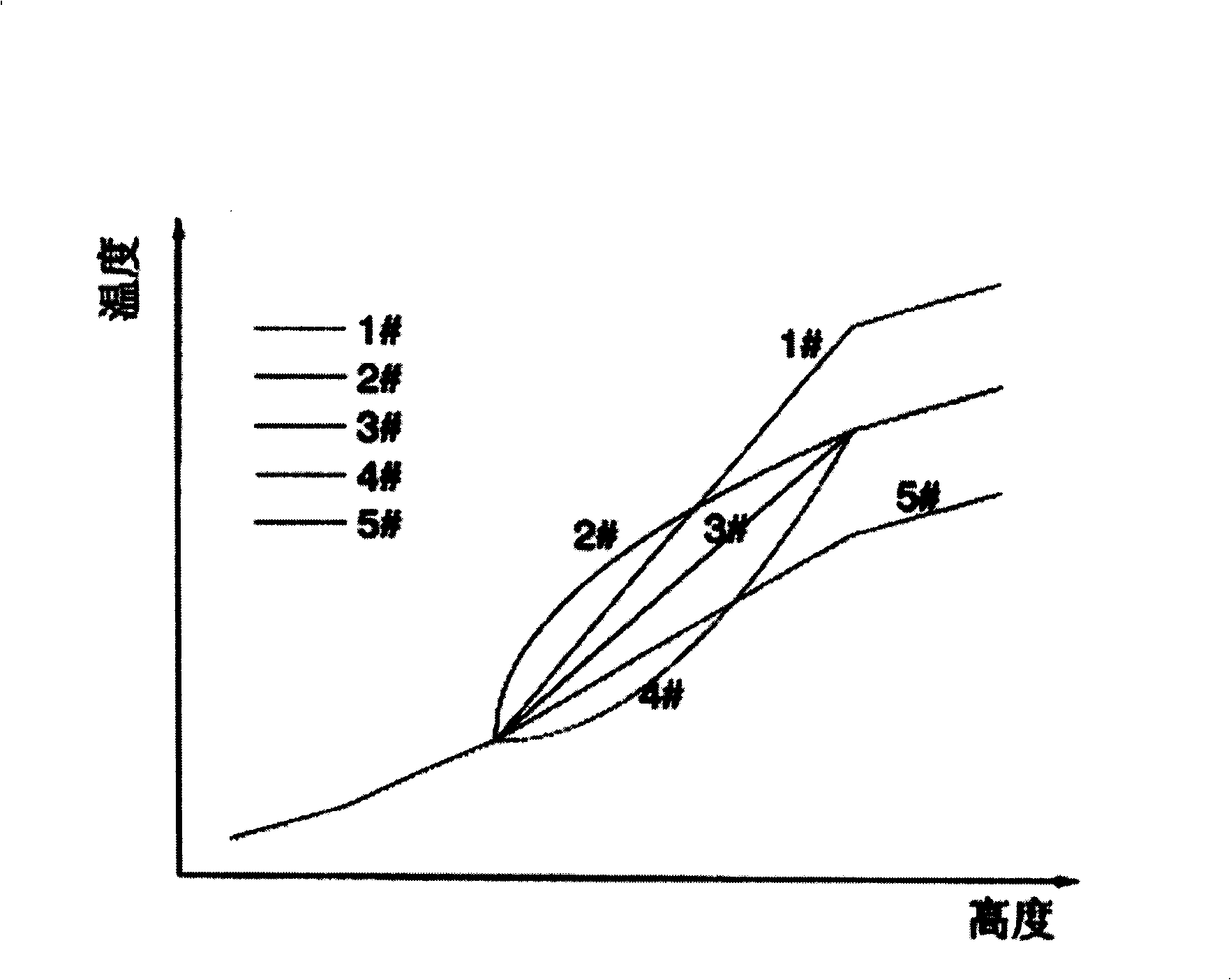

[0021] Such as figure 2 As shown in 1#, a heating cylinder with a radius of R=60mm and H=300mm is made of high-purity graphite resistance heating material. according to figure 1 The trend of the partition groove E is to slot the heating element, where: H A =50mm,H B =120mm,H C =50mm,H D = 40mm; T 1 =2.2mm, T 2 =2.5mm, T 3 = 4mm, T 4 =5mm, T 5 = 5 mm. The transition from section thickness T2 to T3 is a straight line. The prepared heating element is placed in the crystal growth furnace, the furnace is closed, vacuumized, and the temperature is raised after filling the gas. The temperature distribution of the crystal growth area is as follows: image 3 1# line in.

Embodiment 2

[0023] Such as figure 2 As shown in 2#, a heating cylinder with a radius of R=60mm and H=300mm is made of high-purity graphite resistance heating material. according to figure 1 The trend of the middle groove is to slot the heating element, among which: H A =50mm,H B =120mm,H C =50mm,H D = 40mm; T 1 =2.5mm, T 2 = 3mm, T 3 =4.5mm, T 4 =5mm, T 5 = 5mm. Wherein the transition from section thickness T2 to T3 is a concave line. The prepared heating element is placed in the crystal growth furnace, the furnace is closed, vacuumized, and the temperature is raised after filling the gas. The temperature distribution of the crystal growth area is as follows: image 3 Middle 2# line.

Embodiment 3

[0025] Such as figure 2 As shown in 3#, the high-purity graphite resistance heating material is used to make a heating cylinder with a radius of R=60mm and H=300mm. according to figure 1 The trend of the middle groove is to slot the heating element, among which: HA =50mm,H B =120mm,H C =50mm,H D = 40mm; T 1 =2.5mm, T 2 = 3mm, T 3 =4.5mm, T 4 =5mm, T 5 = 5mm. The transition from section thickness T2 to T3 is a straight line. The prepared heating element is placed in the crystal growth furnace, the furnace is closed, vacuumized, and the temperature is raised after filling the gas. The temperature distribution of the crystal growth area is as follows: image 3 Middle 3# line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com