Decelerating casing of decelerating clutch of washing machine

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve the problems of high cost, low production efficiency, complex processing technology, etc., and achieve the effect of low cost, high production efficiency and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

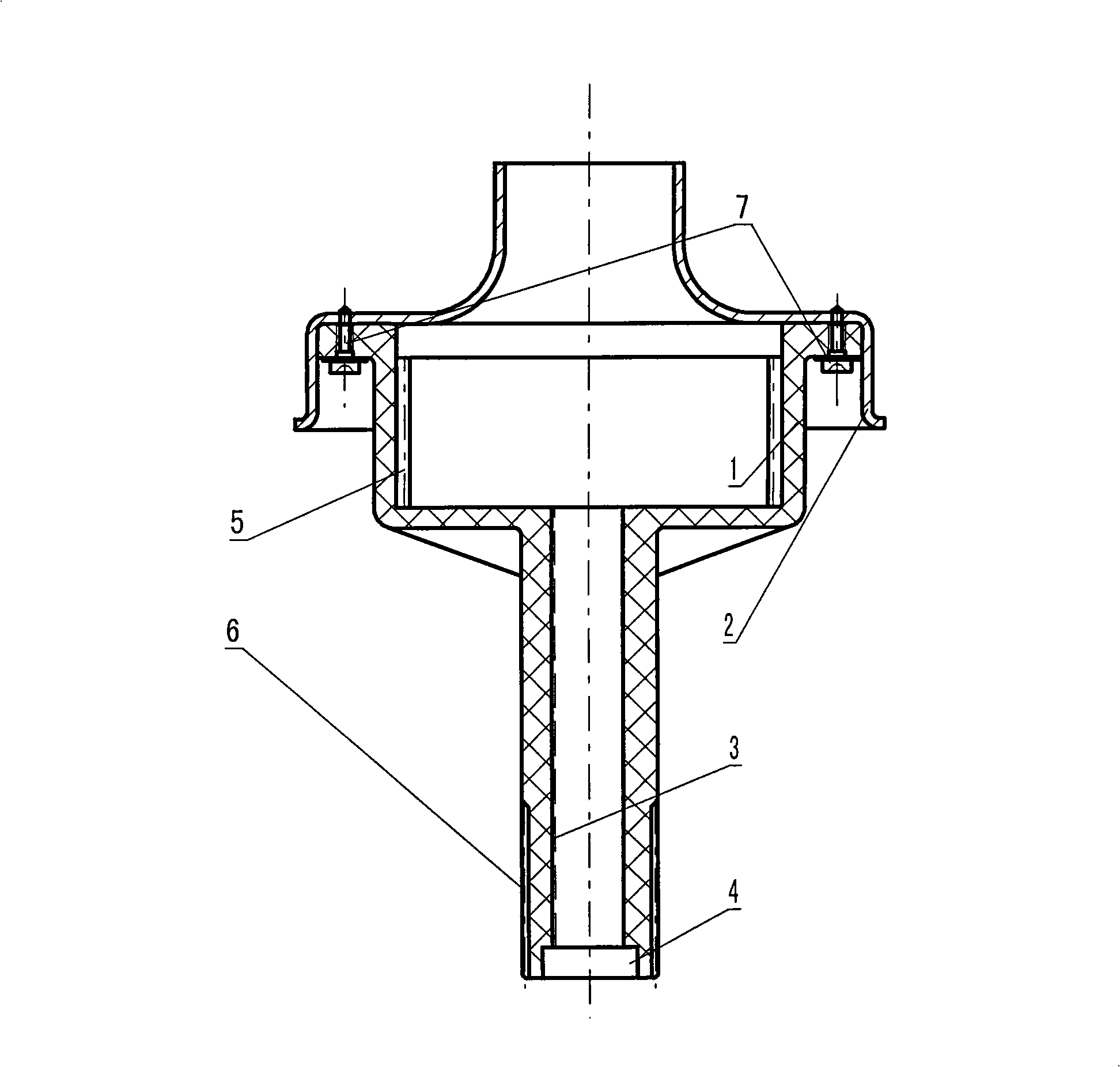

[0019] Referring to FIG. 1 , a washing machine deceleration clutch deceleration housing is composed of an input shaft sleeve 1 and a brake disc 2 . The input shaft sleeve 1 is composed of two parts that are connected together, wherein the diameter of one part is larger than the other part, and the inside of the larger diameter part is a cavity that can accommodate the gear train, and the inner wall is provided with internal teeth 5; the diameter of the input shaft sleeve 1 is larger. The inner wall of the small part is provided with an oil guide groove 3, and the end is provided with an oil seal cavity 4; the outer wall of the input shaft sleeve 1 with a smaller diameter is provided with a spline 6; in terms of processing, it is best to use engineering plastic injection molding, or it can be Made of zinc and aluminum alloy. The brake disc 2 is a metal drawn part made of steel plate, which fits on the end of the larger diameter part of the input shaft sleeve, and the fastening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com