Expansion machine rotor for highly pressurized liquid throttling

A high-pressure liquid and expander technology, which is applied in the direction of reaction engines, mechanical equipment, engine components, etc., can solve the problems of high requirements and large volume of liquid expanders, and achieve energy consumption reduction, flexible braking methods, and realization of The effect of high-power high-speed transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

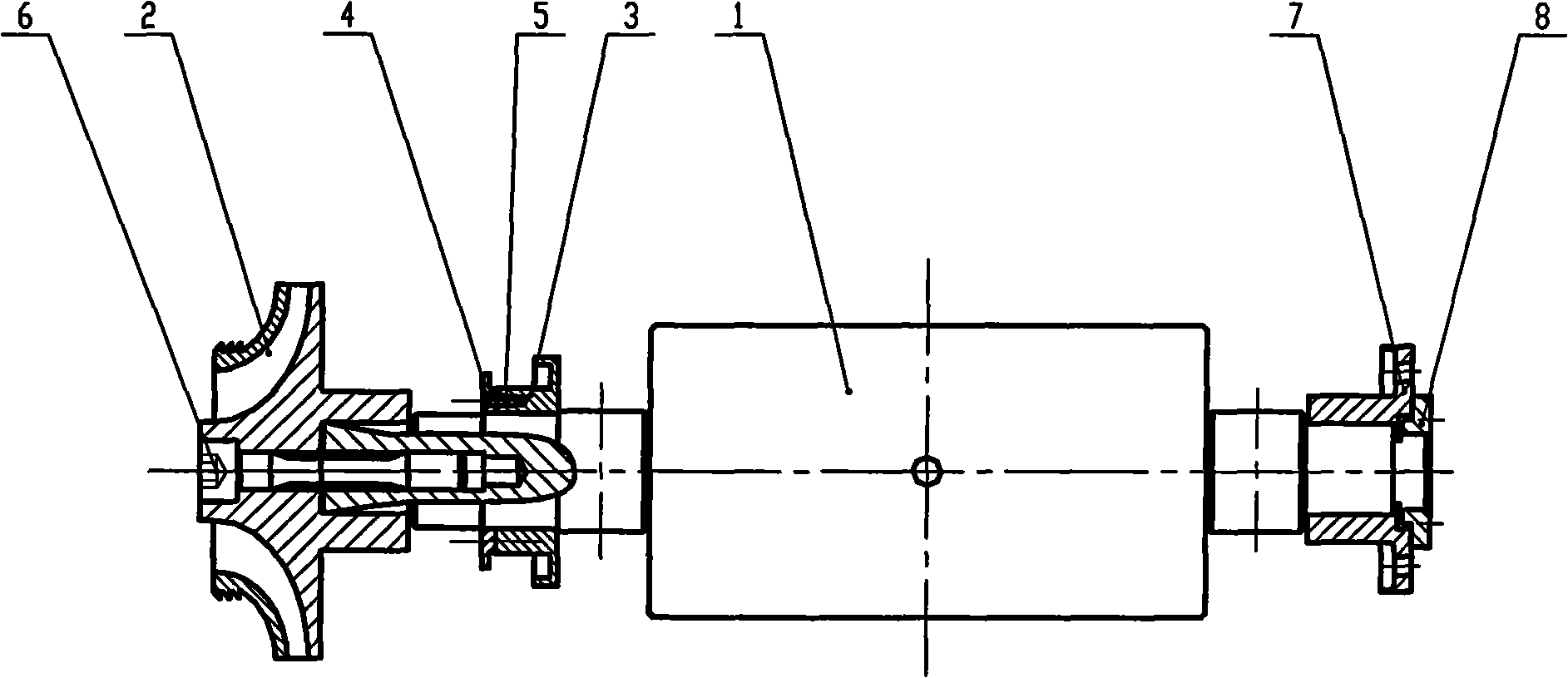

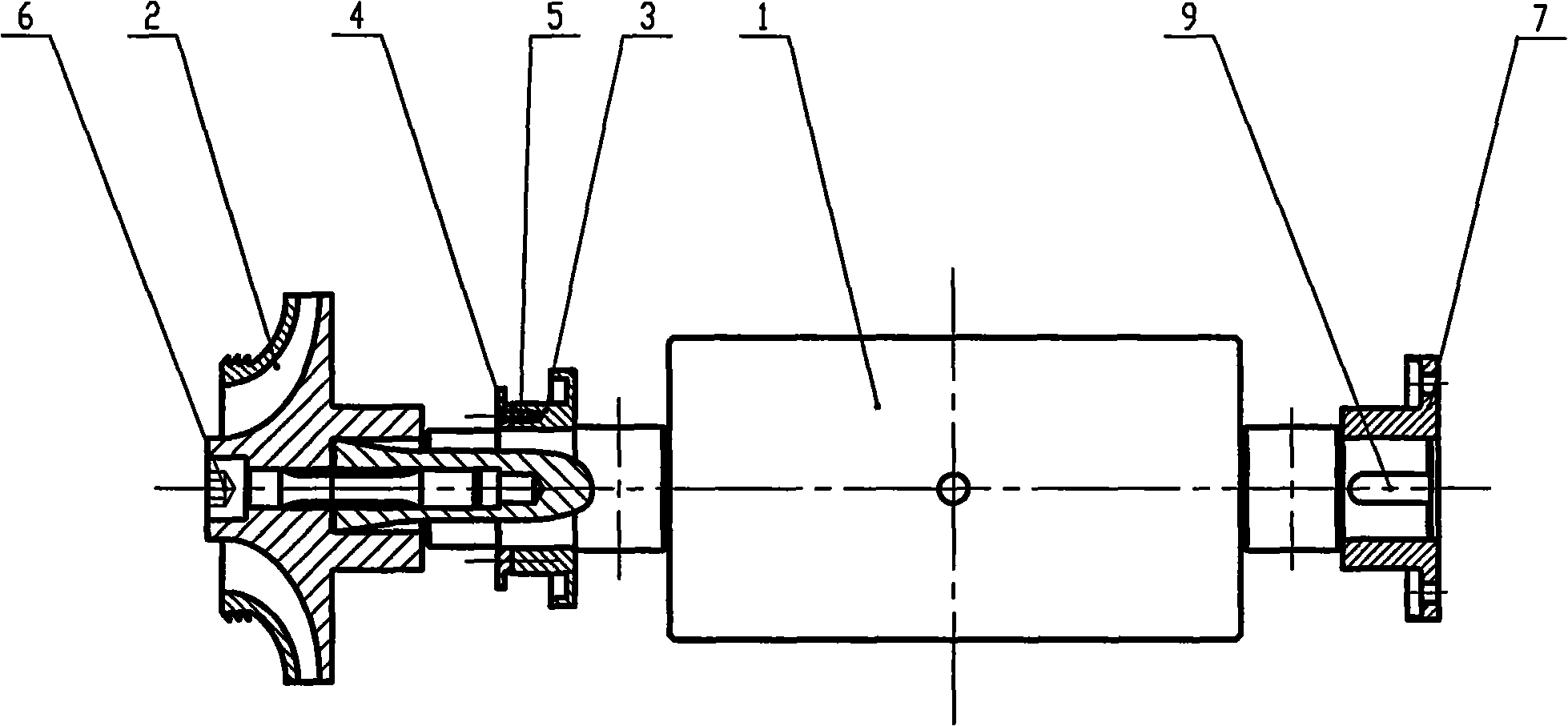

[0022] like figure 1 and figure 2 As shown, two examples of a liquid expander rotor, such as figure 1 In the example of the rotor shown, the main shaft 1 at the gearbox end is connected with the diaphragm coupling 7 through a triangular shaft and fixed with a fastening nut 8 . like figure 2 In the rotor example shown, the main shaft can also be connected to the diaphragm coupling 7 via a key 9 . The oil throwing ring 3 and the oil throwing ring baffle 4 are fixed by the hexagon socket head screw 5 .

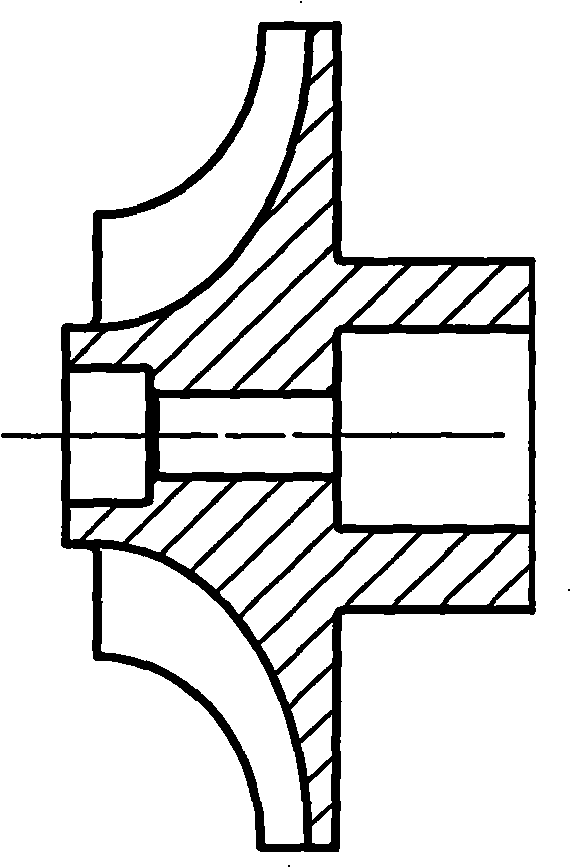

[0023] The impeller 2 adopts a radial flow centripetal impeller, which can be a closed structure or a semi-open structure ( image 3 ), or fully open structure ( Figure 4 ). There is a triangular hole at the center line of the impeller, which is connected with the triangular journal of the main shaft. The impeller radially enters the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com