Automobile engine cooling water pump

A technology of automobile engine and cooling water pump, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve problems such as single transmission force, many cavitation problems, and belt slippage, so as to reduce moment of inertia, small layout space, The effect of lightening the overall mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

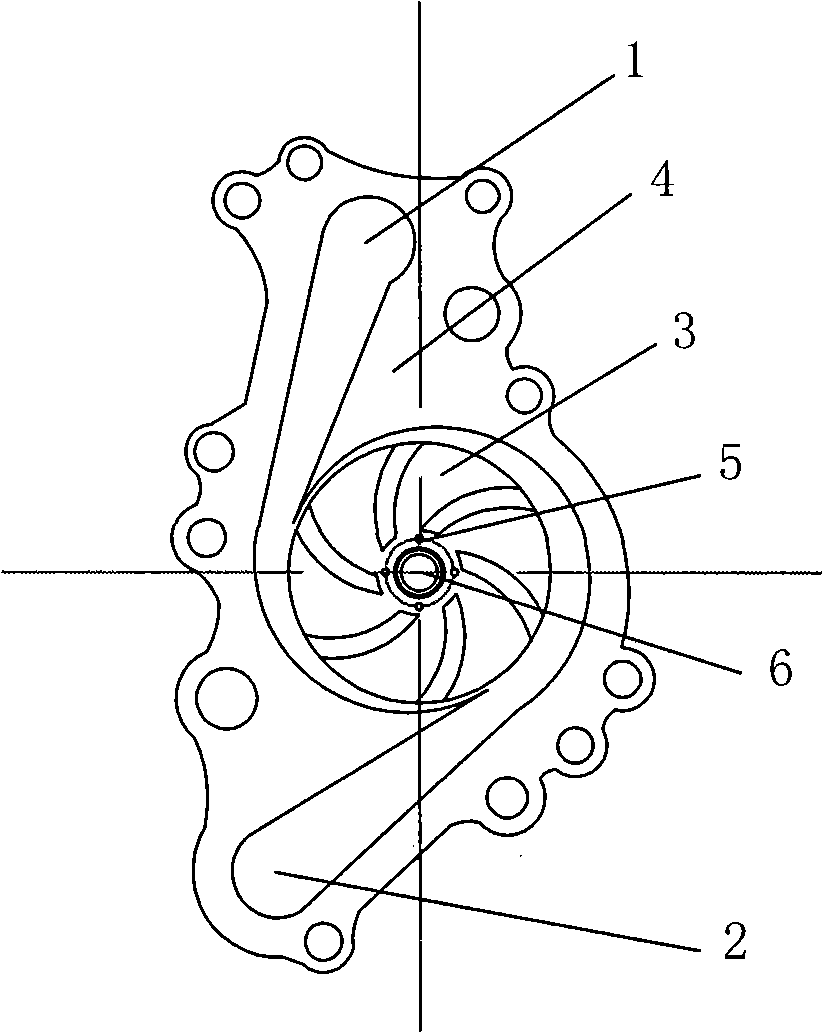

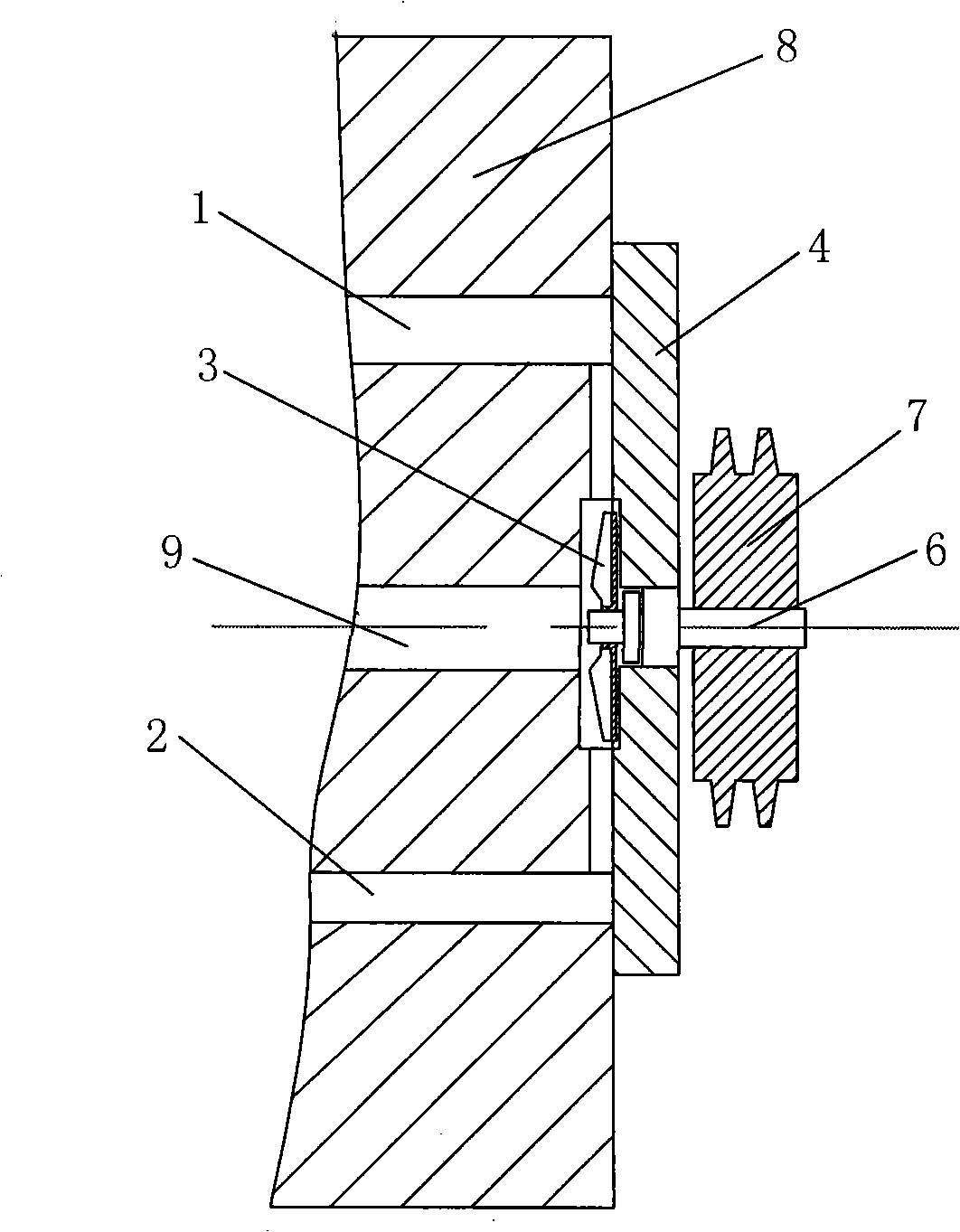

[0016] Such as figure 1 , 2 As shown, a cooling water pump for an automobile engine includes a water pump casing 4 combined with an engine block 8, and the water pump casing 4 is combined with the cylinder block 8 to form a closed cavity, and a water pump impeller 3 driven by a water pump wheel shaft 6 and The water inlet 9 is arranged on the engine block 8 . Two water outlets, ie, a first water outlet 1 and a second water outlet 2 , are respectively arranged on both sides of the water pump housing 4 . The water pump casing adopts a cover plate structure, and the water pump casing is combined with the cylinder body to form a closed cavity, which reduces the size of the water pump casing and makes the engine structure more compact.

[0017] A pressure relief hole 5 is provided at the inlet of the blade of the water pump impeller 3 . The pressure relief holes 5 are preferably 4, evenly distributed around the circumference. This not only balances the water pressure before and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com