Inner powder dust on-line checking method for high pressure gas pipeline and its device

A technology for natural gas pipelines and detection devices, which is applied to sampling devices, analysis materials, instruments, etc., and can solve problems such as high dust concentration and low dust concentration of natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

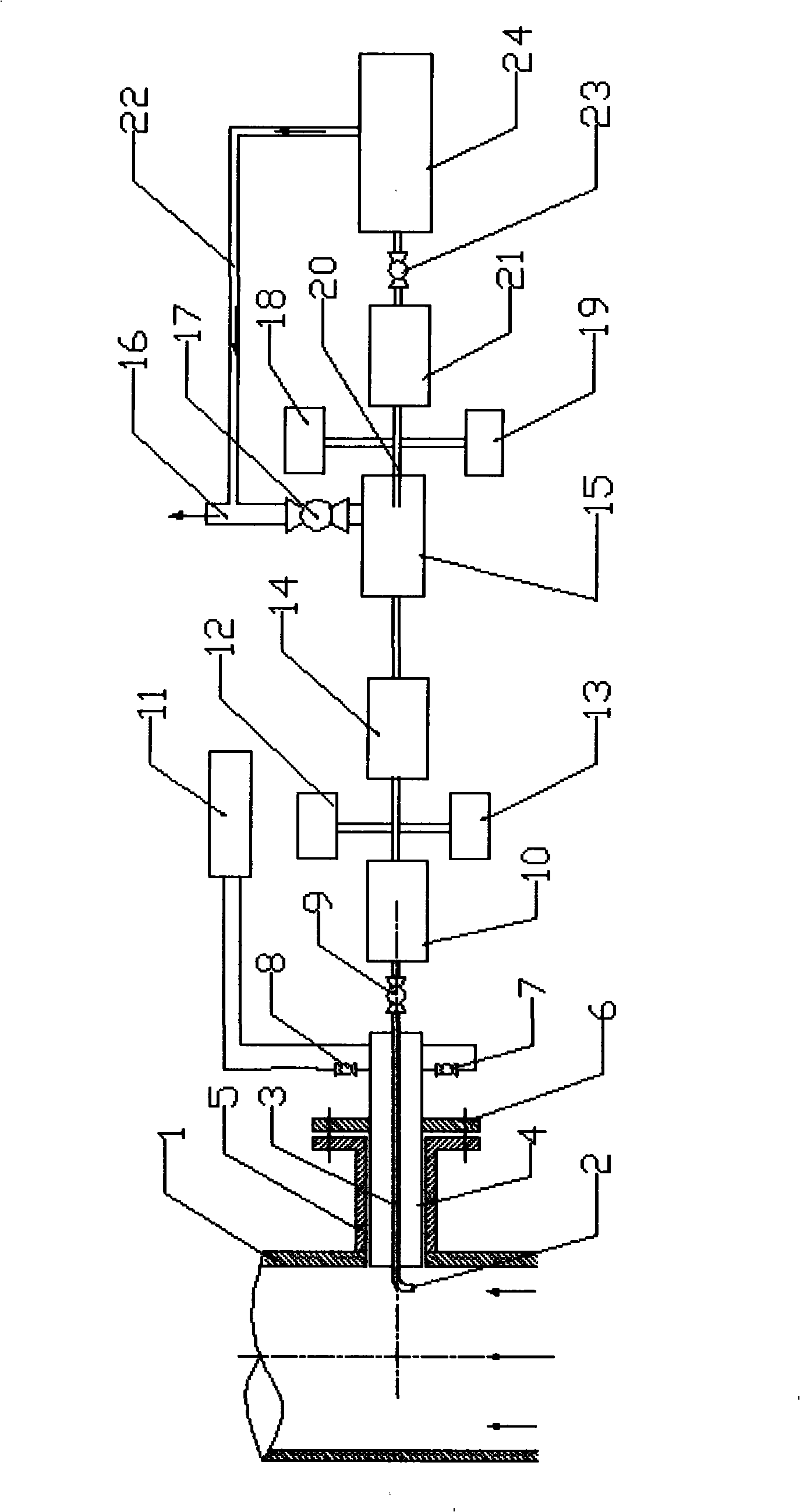

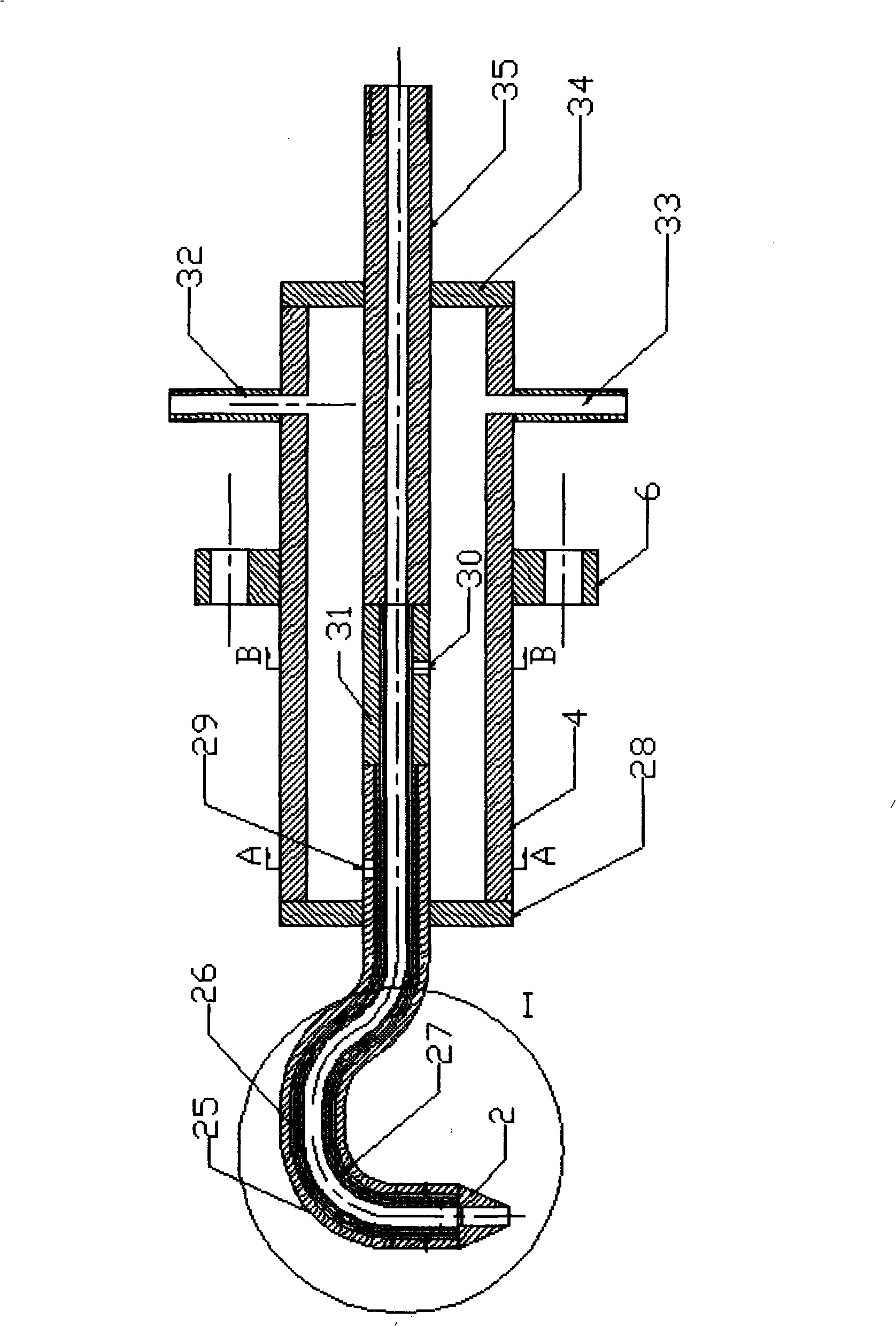

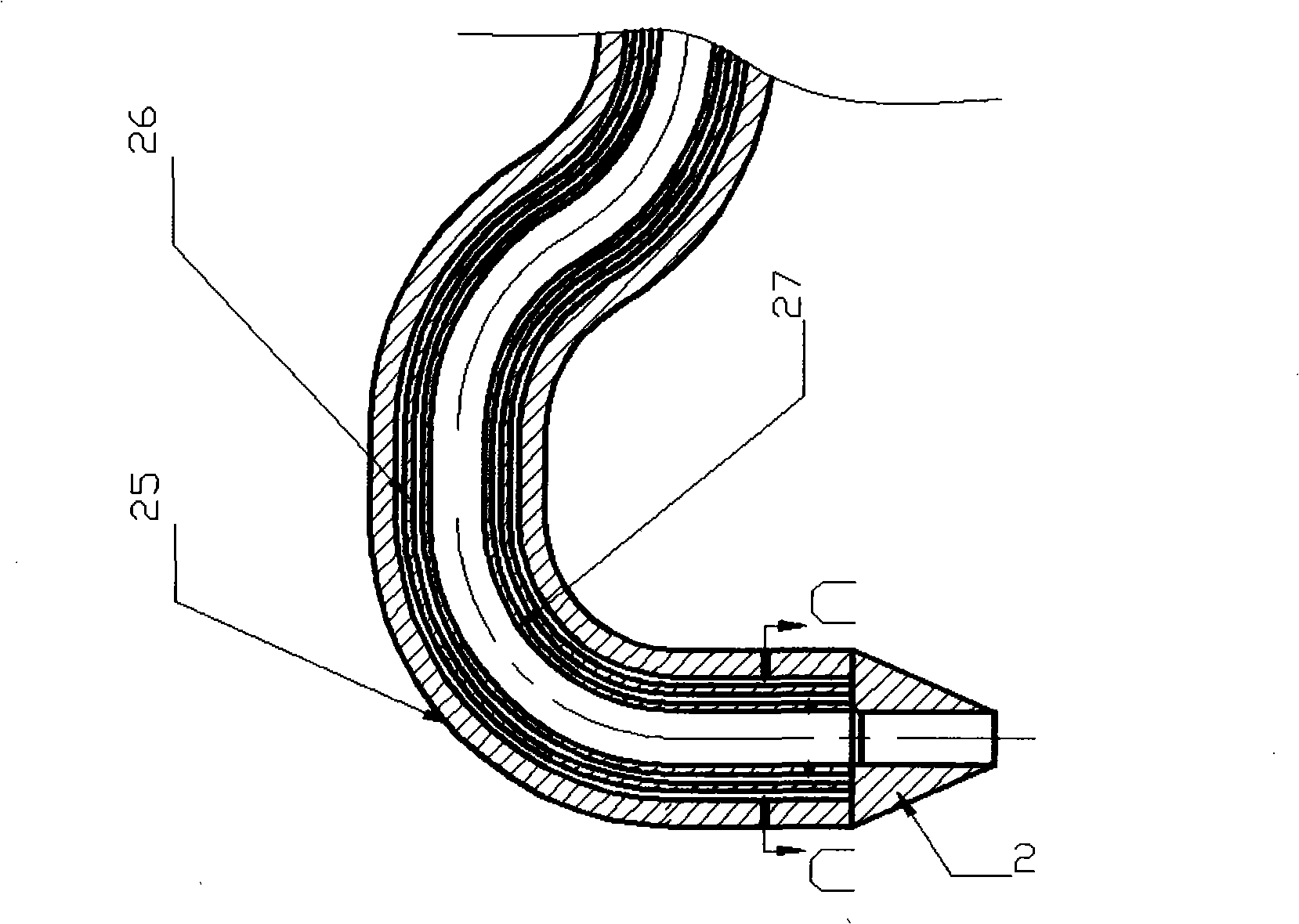

[0066] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype, its composition is as follows Figure 1-Figure 9 shown.

[0067] The pipe joint 5 is inserted into the high-pressure natural gas pipeline 1, and the inner and outer chambers of the sampling nozzle 2 of the sampling system inserted into the pipe joint 5 are separated into two parts by the pressure sealing sleeve 4 (see figure 2 ), and respectively connect the differential pressure sensor 11 of the instrument test system through the ball valve I7 and the ball valve II8 for detection; at the same time, the sampling pipe 3 in the sampling system is connected with the flow control valve I9 and the condensing dryer 10 in sequence, and is also connected with the flow sensor of the instrument test system 14 connection, and a pressure sensor I12 and a temperature sensor I13 are added between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com