BICMOS circuit buried layer epitaxial method by cylinder epitaxial furnace

An epitaxial furnace and barrel-type technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems that cannot meet the performance requirements of VLSI systems, power consumption and integration can not meet the needs of VLSI technology development, etc., to achieve The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

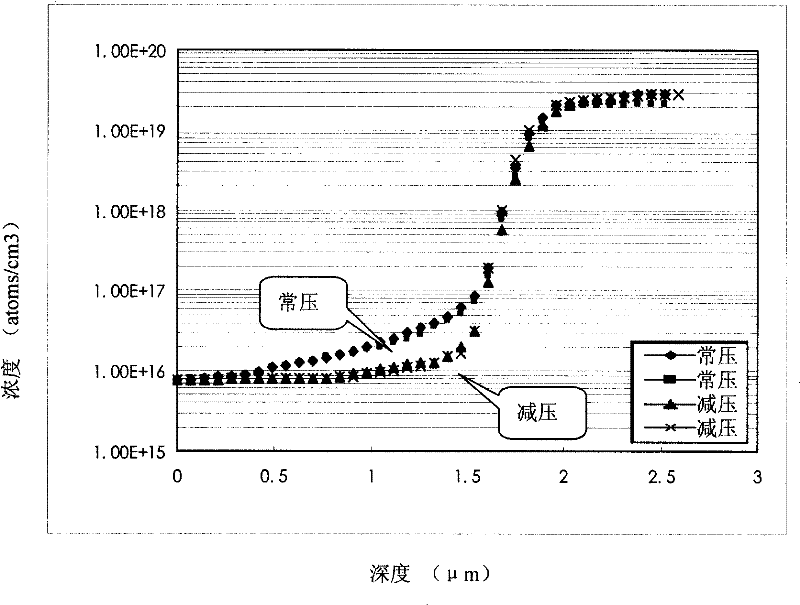

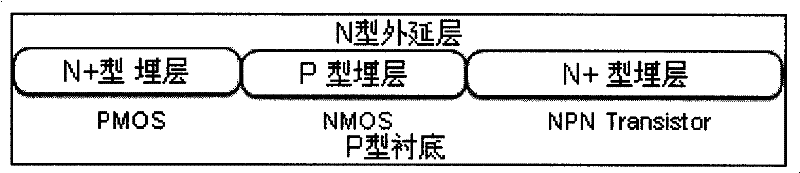

[0036] Embodiment 1: Utilize barrel-type epitaxial furnace, grow N-type epitaxial layer under reduced pressure on pattern piece (PMOS, NMOS, NPN junction is formed on P-type substrate), obtain the BICMOS raw material of N-type epitaxy.

[0037] First, gradually raise the temperature of the barrel epitaxy furnace to the epitaxial growth temperature (1000℃~1200℃) at a certain rate (50-70℃ / min);

[0038] Then pass through HCl (flow rate 1-5L / min, corrosion time 2-5min) to corrode the graphic sheet, control the amount of corrosion removal, so as to obtain a better surface state suitable for subsequent treatment;

[0039] Then vacuumize the chamber so that the vacuum degree reaches 60-100 Torr, which meets the requirements of decompression epitaxial growth;

[0040] Then feed 700~800L / min SiH 2 Cl 2 And 150 ~ 180mL / min doping source pH 3 , at a growth rate of 0.1-0.5um / min for epitaxy, through the main hydrogen flow (90-180L / min), rotating hydrogen flow (10-50L / min), JET (nozzle...

Embodiment 2

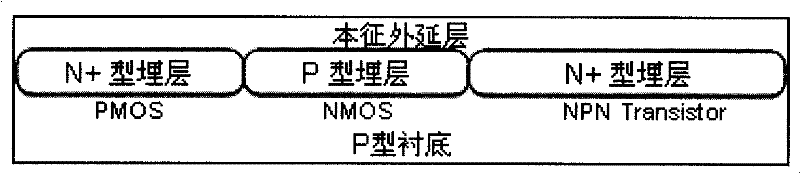

[0043] Embodiment 2: Using a barrel epitaxy furnace, an intrinsic epitaxial layer is grown under reduced pressure on a pattern sheet (NMOS and NPN junctions are formed on a P-type substrate) to obtain an intrinsic epitaxial BICMOS raw material.

[0044] First, gradually raise the temperature of the barrel epitaxy furnace to the epitaxial growth temperature (1000℃~1200℃) at a certain rate (50-70℃ / min);

[0045] Then pass HCl (flow rate 1 ~ 5L / min, corrosion time 2 ~ 5min) to corrode the graphic sheet, control the amount of corrosion removal, in order to obtain a better surface state;

[0046] Then vacuumize the chamber so that the vacuum degree reaches 60-100 Torr, which meets the requirements of decompression epitaxial growth;

[0047] Then feed 700~800L / min SiH 2 Cl 2, Intrinsic epitaxy at a growth rate of 0.1-0.5um / min, through the main hydrogen flow rate (90-180L / min), rotating hydrogen flow rate (10-50L / min), JET (nozzle) position and BMV of the epitaxial equipment The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com