Caprolactam composition, method for making a sealing element, and reservoir

A technology of caprolactam and polycaprolactam, which is applied in the fields of containers, tight envelopes, and storage tanks, can solve the problems of increasing the time and cost of manufacturing envelopes, difficulty in obtaining uniform mixtures, and complex preparation of mixtures, and achieves the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Example 1: Examples of components for the preparation of compositions according to the invention

[0128] The components used in the examples below to prepare compositions according to the invention are as follows:

[0129] -ε-caprolactam monomer (I): AP CAPROLACTAME TM , supplier: DSM FibreIntermediate B.V., melting point: 69°C;

[0130] -ε-caprolactam activator (II): AKTIVATOR O TM , supplier: Brüggemann Chemical, form: liquid, melting point: -13°C;

[0131] -ε-caprolactam Catalyst (III): NYRIM 1 CATALYST TM As catalyst (III) (bromure de (hexahydro-2H-azepin-2-onato-N) magnesium, supplier: Brüggemann Chemical, form: flakes at ambient temperature, melting point 70 °C; and

[0132] -ε-caprolactone additive: NYRIM ADDITIVE As additive (IV), sold by DSM RIMNYLON VOF, form: liquid at ambient temperature, boiling point at 760 mm Hg about 260°C, melting point below 0°C.

[0133] The chemical formulas of these components (I), (II), (III) and (IV) are as follows:

[01...

Embodiment 2

[0137] Embodiment 2: the example of the device that is used to carry out the method of the present invention

[0138] To prepare the premix shown in Figure 16A or 16C, Bronk TM Mixer, type NCU 75 / 6. The mixer consists of two chambers (compartments) made of stainless steel into which caprolactam + catalyst mixture is introduced on one side and caprolactam + activator + additive mixture on the other side. Each chamber's internal mechanical system can mix its two premixes and preheat them.

[0139] The individual chambers of the mixer are equipped with a system that makes it possible to inject dry nitrogen into the chambers to degas the components used and keep them under a dry and inert atmosphere.

[0140] The chambers of the mixer are also equipped with metering pistons capable of injecting quantitative amounts of each premix into the rotating mould.

[0141] The mixing or contacting between the two premixes takes place outside the mixer using a double-channel nozzle which ...

Embodiment 3

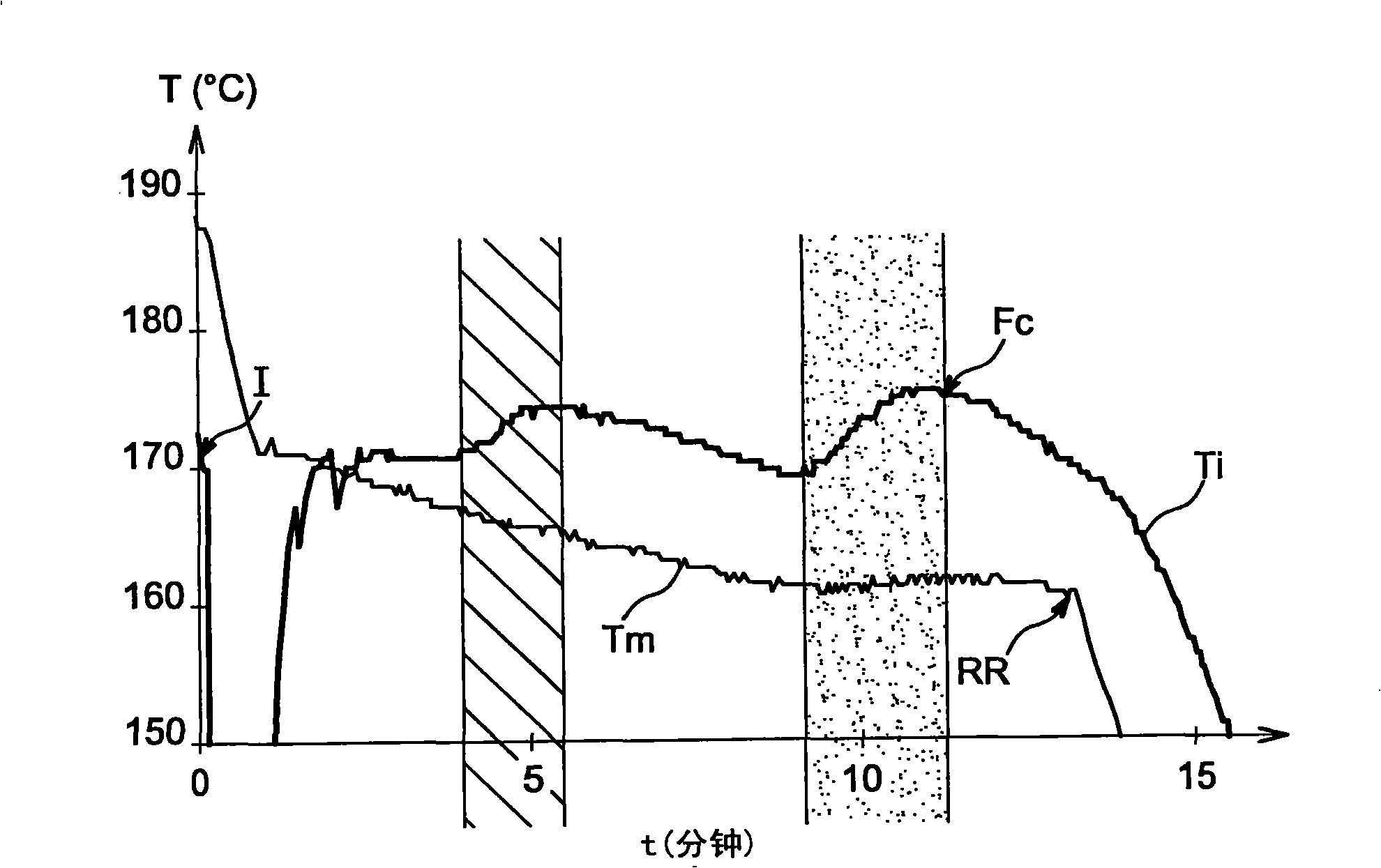

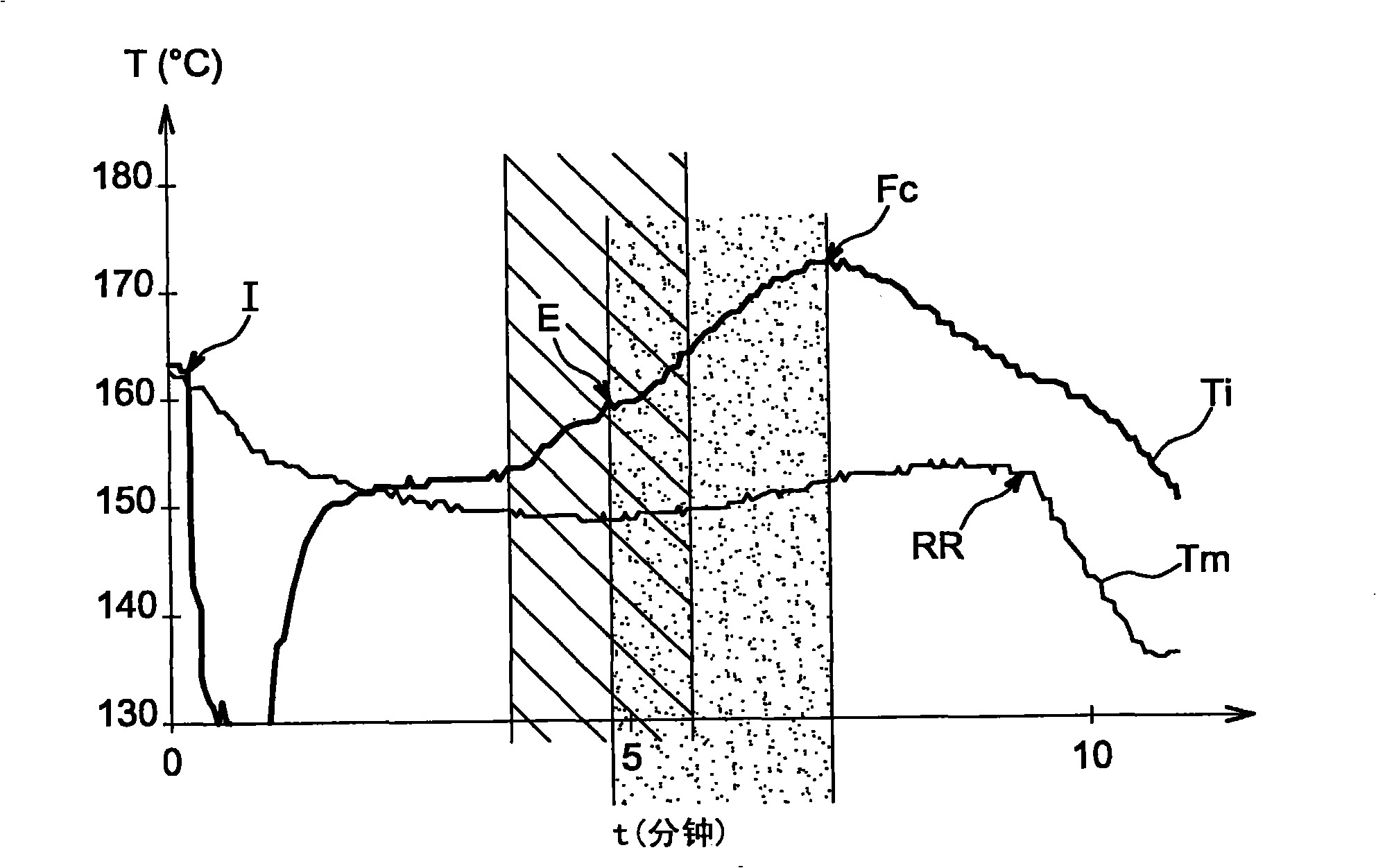

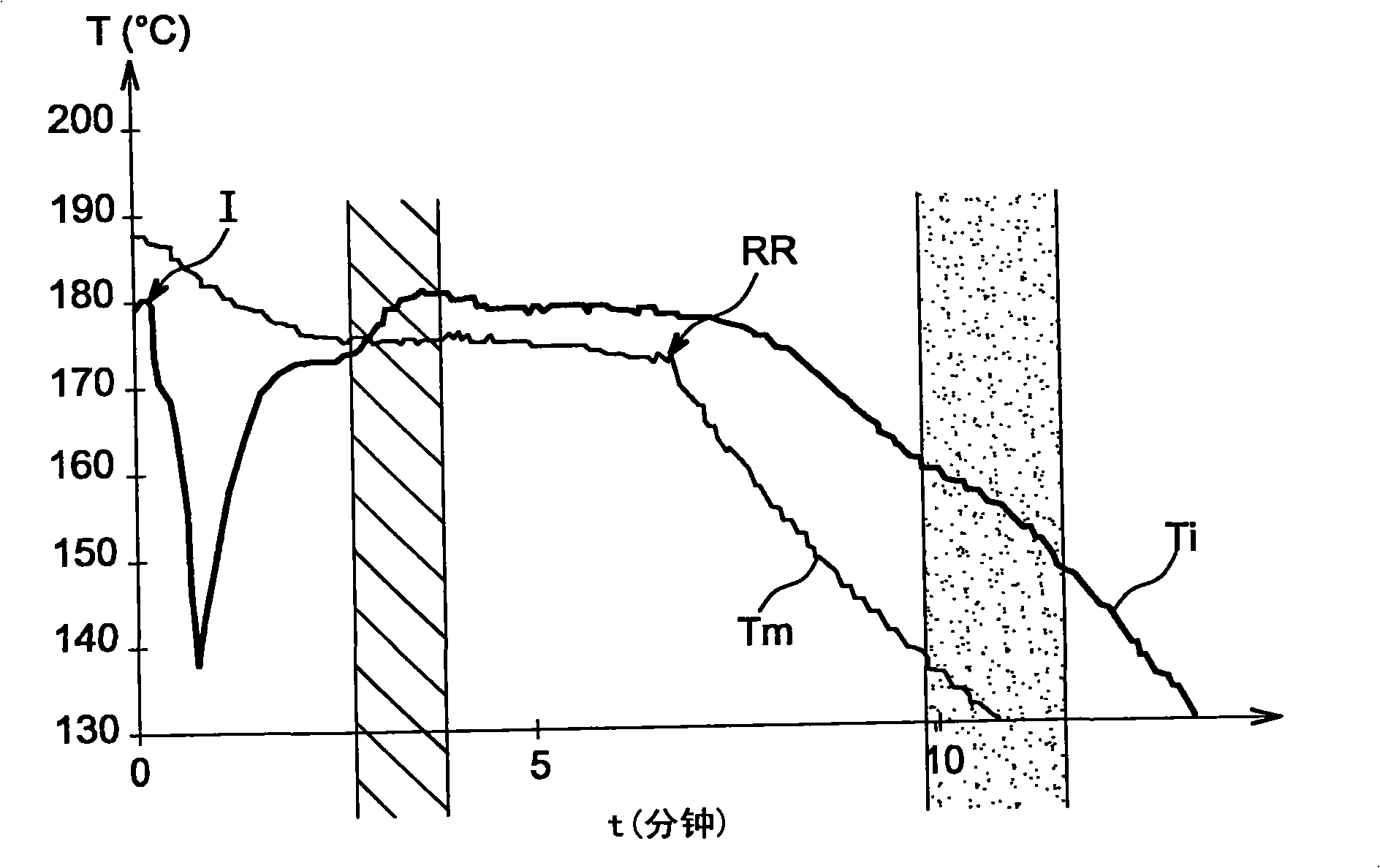

[0145] Embodiment 3: the preparation of envelope and the test to composition of the present invention

[0146] In % by weight, the composition used in this example was as follows: 80.6% ε-caprolactam monomer, 0.4% activator, 4% catalyst and 15% additive. In this example, the total amount of composition used to form the envelope was 397 g. The resulting envelope had a volume of 3L.

[0147] Immediately after weighing the components, the ε-caprolactam monomer and ε-caprolactam catalyst were purged with dry nitrogen.

[0148] The components were preheated, mixed together, and then quickly introduced into the rotating mold as shown in Figure 16B. The rotary mold is heated in an oven to a temperature of 160 to 190°C.

[0149] The mold rotates at a spindle speed of 9 rpm and a counter spindle speed of 6 rpm. The ratio of speed (primary / secondary ratio) is equal to 1.5.

[0150] attached Figures 1 to 3 Measurements at various temperatures performed in this example are compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com