Manufacture method of wedge rubber shoes

A manufacturing method and technology for rubber shoes are applied in the manufacturing field of rubber shoes, which can solve the problems of broken bottom, easy hardening and high production cost, and achieve the effects of simple manufacturing process, low cost, and improved added value and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

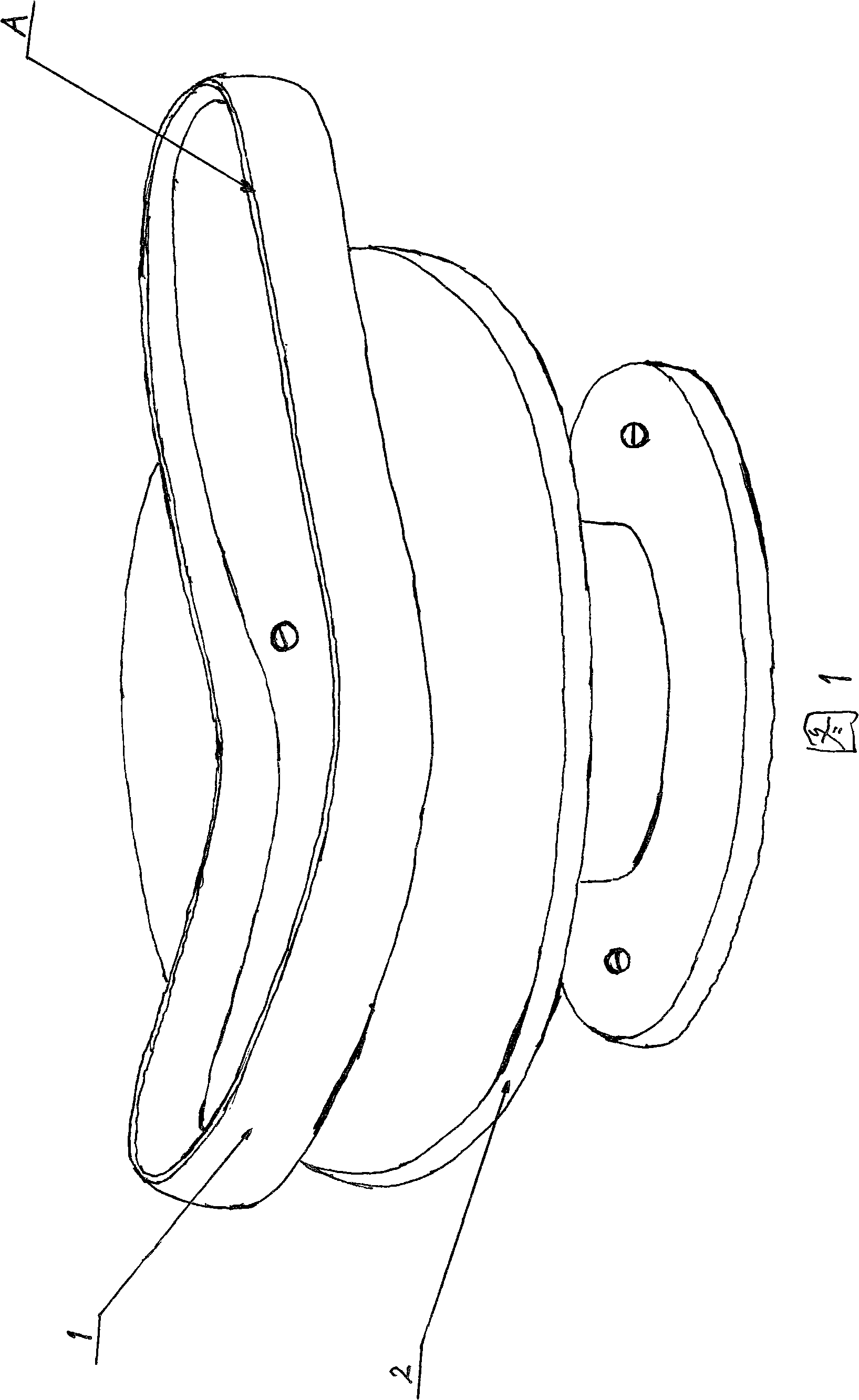

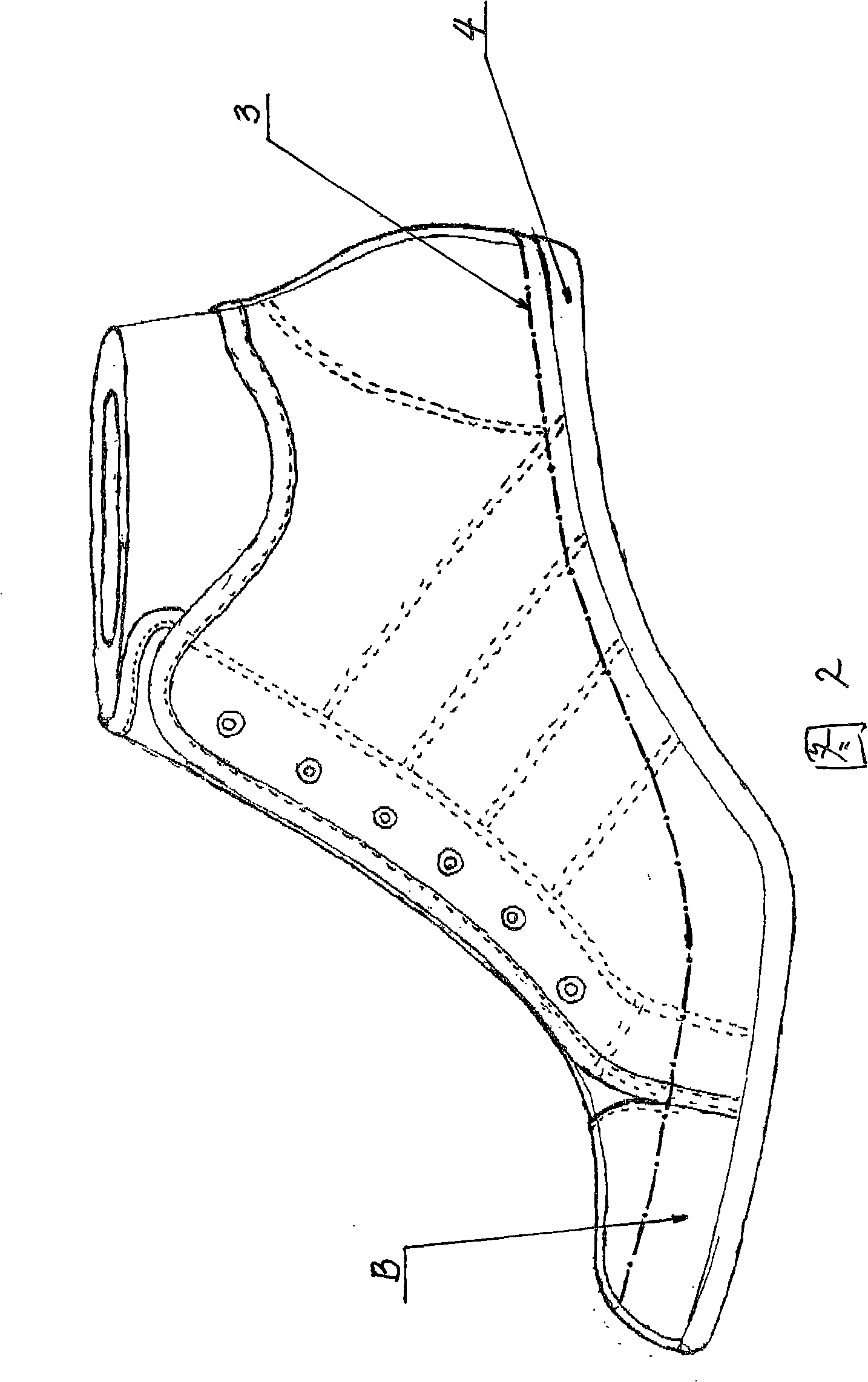

[0009] The manufacturing method of wedge rubber shoes of the present invention is: with reference to Fig. 1, Fig. 2, at first put the clamped upper of a shoe (that is, the upper of a shoe with an aluminum last and contains the middle bottom 4, which is completed by known technology) on a special drawing In the line mold 1, follow the (upper) edge of the line drawing mold (part A as shown in Figure 1) to use a fading pen to draw the line and position the lower part of the upper of the shoe for a week (you can also use a rotating device 2 to make the line draw Mold 1 and clamped upper of a shoe rotate jointly and draw positioning line one week at the bottom of this upper of a shoe), and along this drawn positioning line 3 (represented with dotted line shown in Figure 2) to upper of a shoe bottom (as shown in Fig. Part B shown in 2) carries out glue brushing treatment, then (using an oven) to dry, and then paste "inner midsole rubber strip" on the bottom of the dried shoe upper. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com