Vehicle braking kinetic-energy regeneration device

A vehicle brake and regeneration device technology, which is applied in the direction of power devices, air pressure power devices, vehicle components, etc., can solve the problems of poor practical applicability and poor energy saving effect, so as to improve fuel economy, prolong service life, The effect of not being easily polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

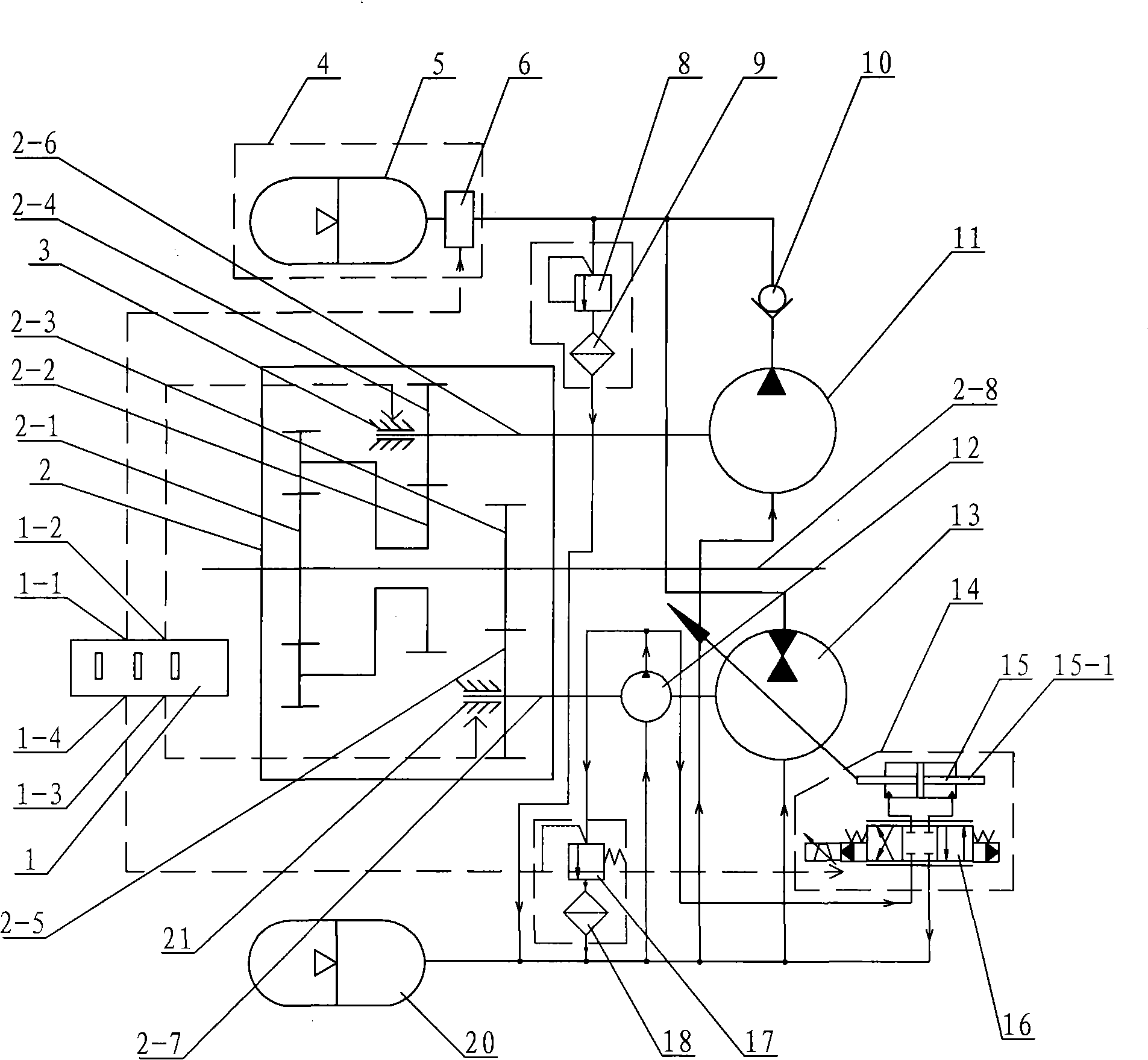

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment consists of a central controller 1, a planetary gear mechanism 2, a first brake 3, an accumulator assembly 4, a high-pressure hydraulic accumulator 5, a two-way electro-hydraulic reversing valve 6, a first relief valve 8. First filter 9, one-way valve 10, charge pump 11, control oil circuit hydraulic pump 12, hydraulic pump motor 13, hydraulic pump motor control assembly 14, second relief valve 17, second filter 18, low pressure The hydraulic accumulator 20 and the second brake 21 are made up, and the planetary gear mechanism 2 is made up of the first driving wheel 2-1, the second driving wheel 2-2, the third driving wheel 2-3, the first driven wheel 2-4, the second driving wheel Two driven wheels 2-5, the first driven shaft 2-6, the second driven shaft 2-7 and the driving shaft 2-8 are composed of the first driving wheel 2-1, the second driving wheel 2-2 and the third driving w...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Describe this embodiment, the hydraulic pump motor control assembly 14 of this embodiment is composed of a variable oil cylinder 15 and an electro-hydraulic servo valve 16, the oil inlet port of the electro-hydraulic servo valve 16 is connected with the oil outlet port of the hydraulic pump 12 in the control oil circuit, The oil outlet port of the electro-hydraulic servo valve 16 is connected with the oil inlet port of the variable oil cylinder 15, the oil inlet port of the electro-hydraulic servo valve 16 is connected with the oil outlet port of the variable oil cylinder 15, and the piston rod 15-1 in the variable oil cylinder 15 is connected with the hydraulic pump motor 13 connections.

[0009] Working principle: The planetary gear mechanism 2 is installed between the engine and the transmission of the vehicle, the braking system of the original vehicle is retained, and the drive shaft of the original vehicle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com