Sustained-release water reducing agent for cement concrete and method for preparing same

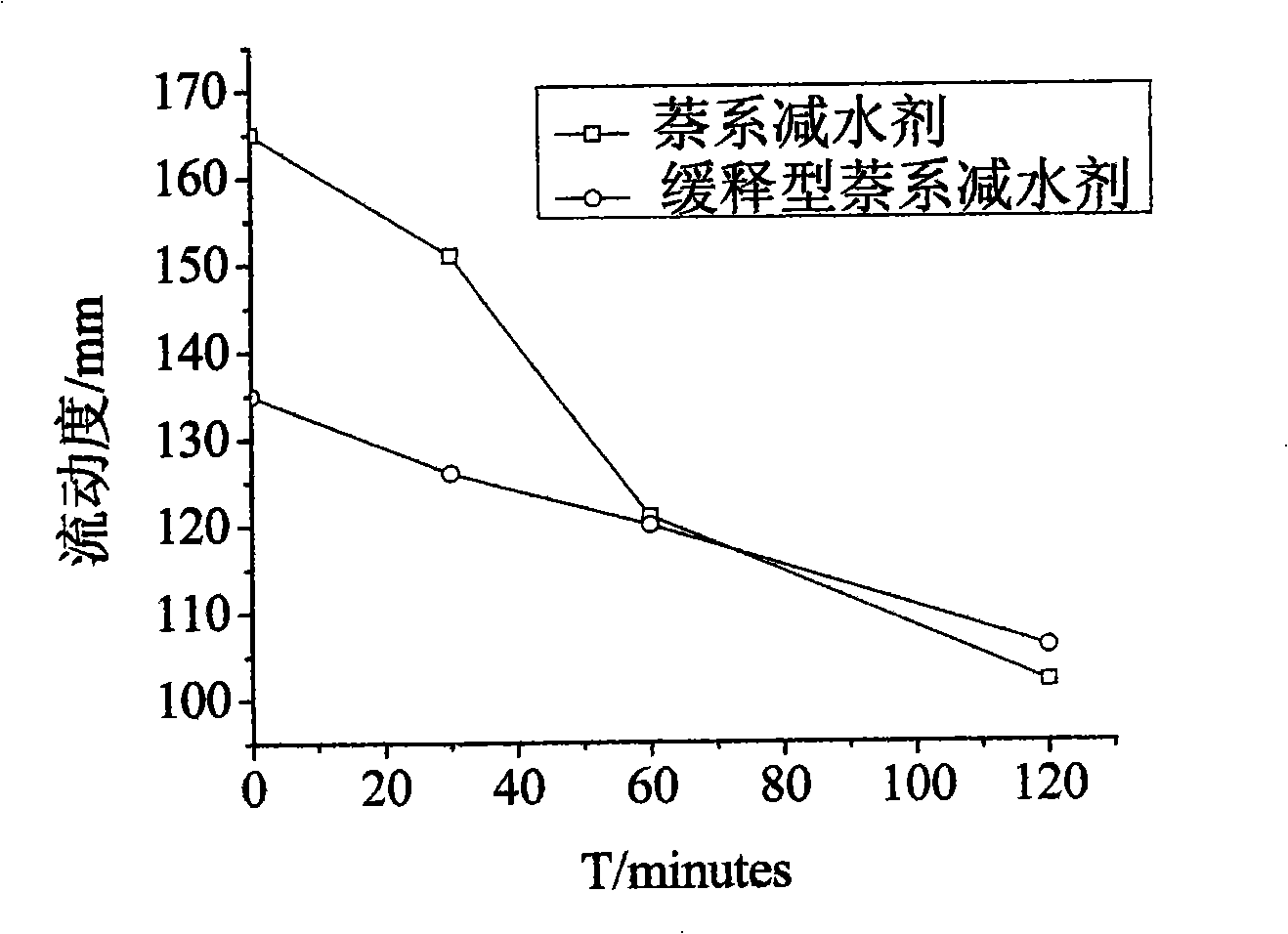

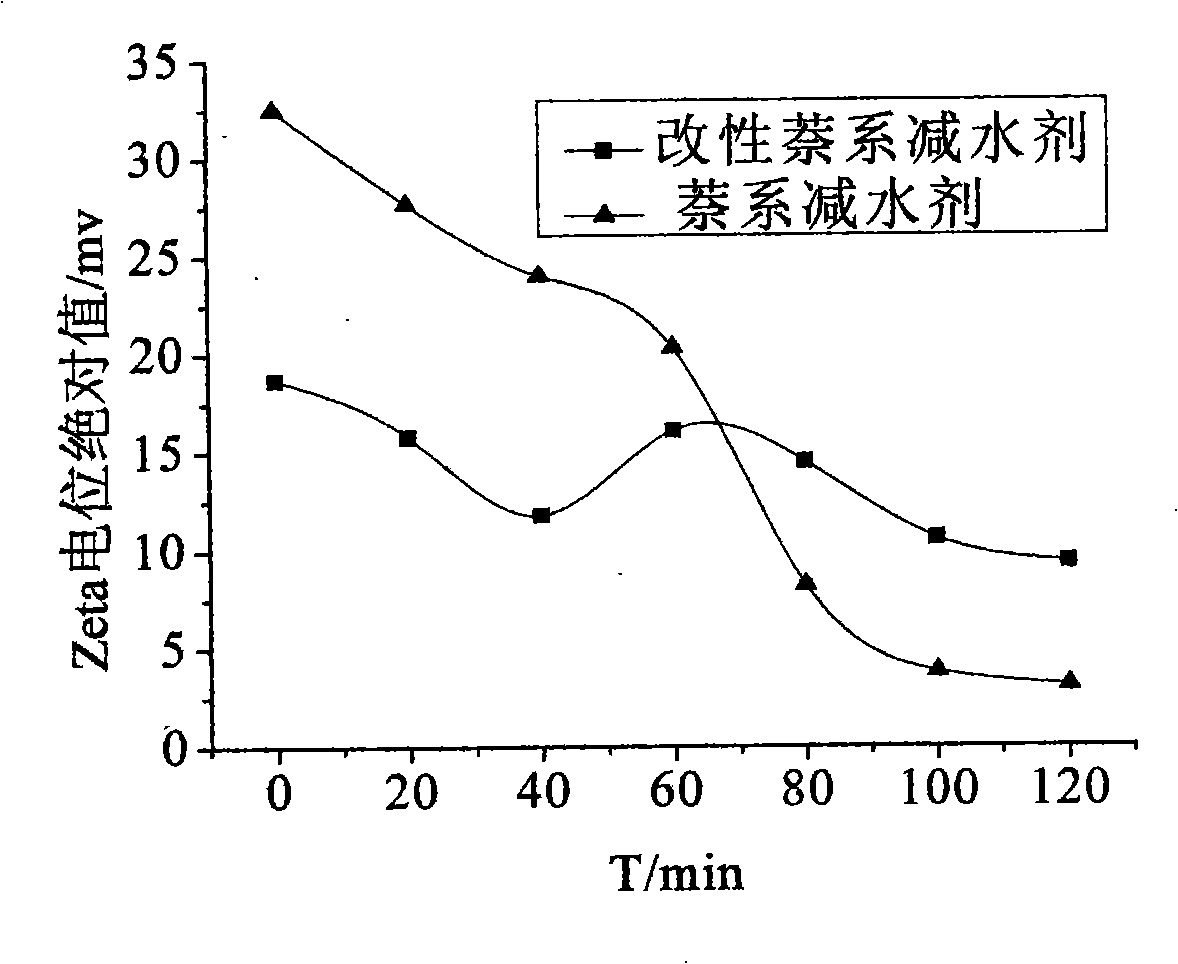

A technology for cement concrete and water reducing agent, which is applied in the field of powdered water reducing agent with slow release effect and its preparation field, can solve the problems that liquid water reducing agent is not easy to store, affects concrete early strength, concrete slump loss and the like, Achieve the effect of solving slump loss, restraining dissolution time and reducing transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a slow-release water reducer for cement concrete, comprising the following steps:

[0045] a, preparation of layered double metal hydroxide:

[0046] According to Mg(NO 3 ) 2 ·6H 2 O:Al(NO 3 ) 3 9H 2 The molar ratio of O is 2:1 and Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, get urea at a molar ratio of 1:3 by urea: the sum of nitrate ions is placed in a reactor, and then add distilled water at a mass ratio of 1:2 by a solid-to-liquid ratio; in an oil bath at 95 to 120°C, Stir the reaction for 12 hours, stop stirring; then put the reaction material in a water bath at 85-95°C for 12 hours; filter, wash the solid with distilled water until pH<8, and dry at 80°C for 8 hours to obtain a layered MgAl bimetallic hydroxide;

[0047] b. Preparation of double metal oxides:

[0048] Calcining the obtained layered MgAl double metal hydroxide at a temperature of 450-550° C. for 2 hours to obtain a MgAl double metal oxide;

[0049] c. Preparati...

Embodiment 2

[0054] A preparation method of a slow-release water reducer for cement concrete, comprising the following steps:

[0055] a, preparation of layered double metal hydroxide:

[0056] According to Mg(NO 3 ) 2 ·6H 2 O:Al(NO 3 ) 3 9H 2 The molar ratio of O is 2:1 and Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, get urea at a molar ratio of 1:5 by urea: the sum of nitrate ions is all placed in the reactor, and then add distilled water at a mass ratio of 1:5 by solid-to-liquid ratio; in an oil bath at 95 to 120°C, Stir the reaction for 48 hours, stop stirring; then put the reaction material in a water bath at 85-95°C for 48 hours; filter, wash the solid with distilled water until pH<8, and dry at 80°C for 12 hours to obtain a layered MgAl bimetallic hydroxide;

[0057] b. Preparation of double metal oxides:

[0058] Calcining the obtained layered MgAl double metal hydroxide at a temperature of 450-550° C. for 4 hours to obtain a MgAl double metal oxide;

[0059] c. Prep...

Embodiment 3

[0064] A preparation method of a slow-release water reducer for cement concrete, comprising the following steps:

[0065] a, preparation of layered double metal hydroxide:

[0066] According to Mg(NO 3 ) 2 ·6H 2 O:Al(NO 3 ) 3 9H 2 The molar ratio of O is 2:1 and Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, get urea at a molar ratio of 1:4 by urea: the sum of nitrate ions is all placed in the reactor, and then add distilled water at a mass ratio of 1:3.5 by the solid-to-liquid ratio; in an oil bath at 95 to 120°C, Stir the reaction for 24 hours, stop stirring; then put the reaction material in a water bath at 85-95°C for 24 hours; filter, wash the solid with distilled water until pH<8, and dry at 80°C for 10 hours to obtain a layered MgAl bimetallic hydroxide;

[0067] b. Preparation of double metal oxides:

[0068] Calcining the obtained layered MgAl double metal hydroxide at a temperature of 450-550° C. for 3 hours to obtain a MgAl double metal oxide;

[0069] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com