Method for enhancing fracture tensile strength of PBI/HP3O4 cast by sol-gel method

A technology of PBI-H3PO4 and tensile strength at break, which is applied in the field of material science and can solve the problem of low tensile strength at break of membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

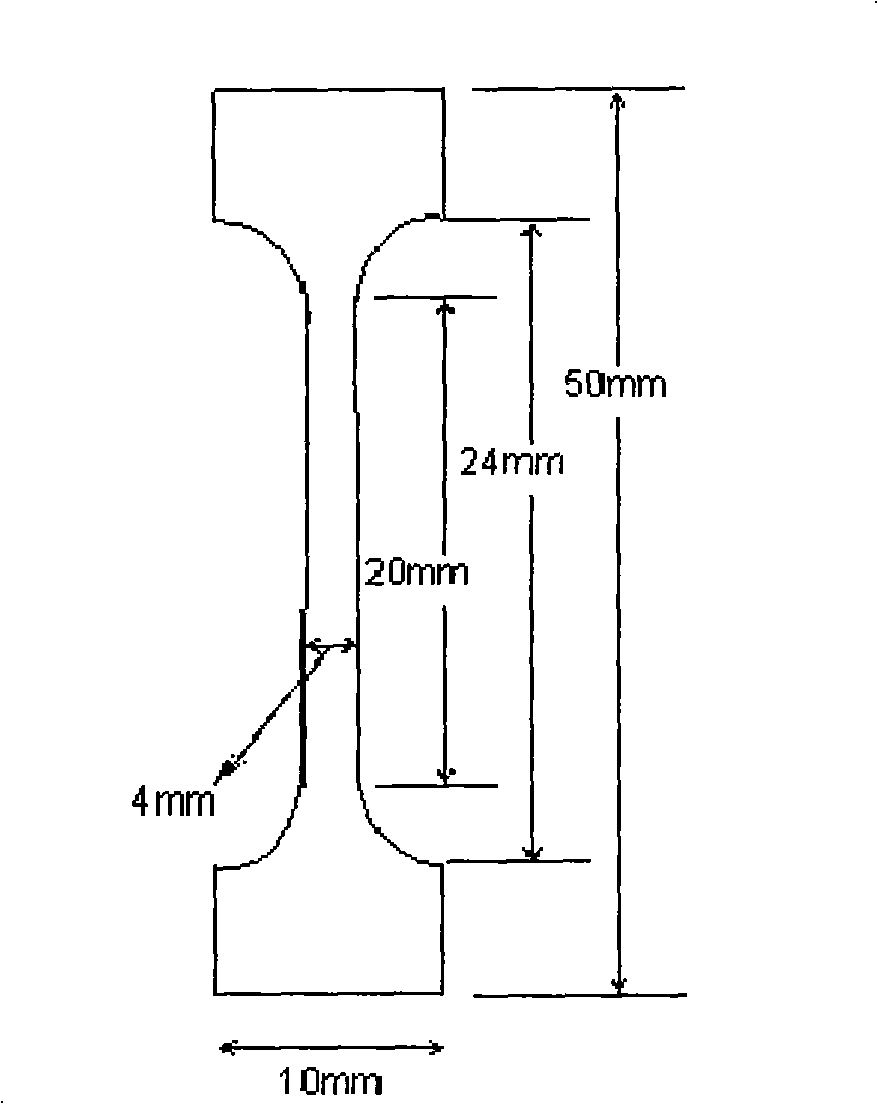

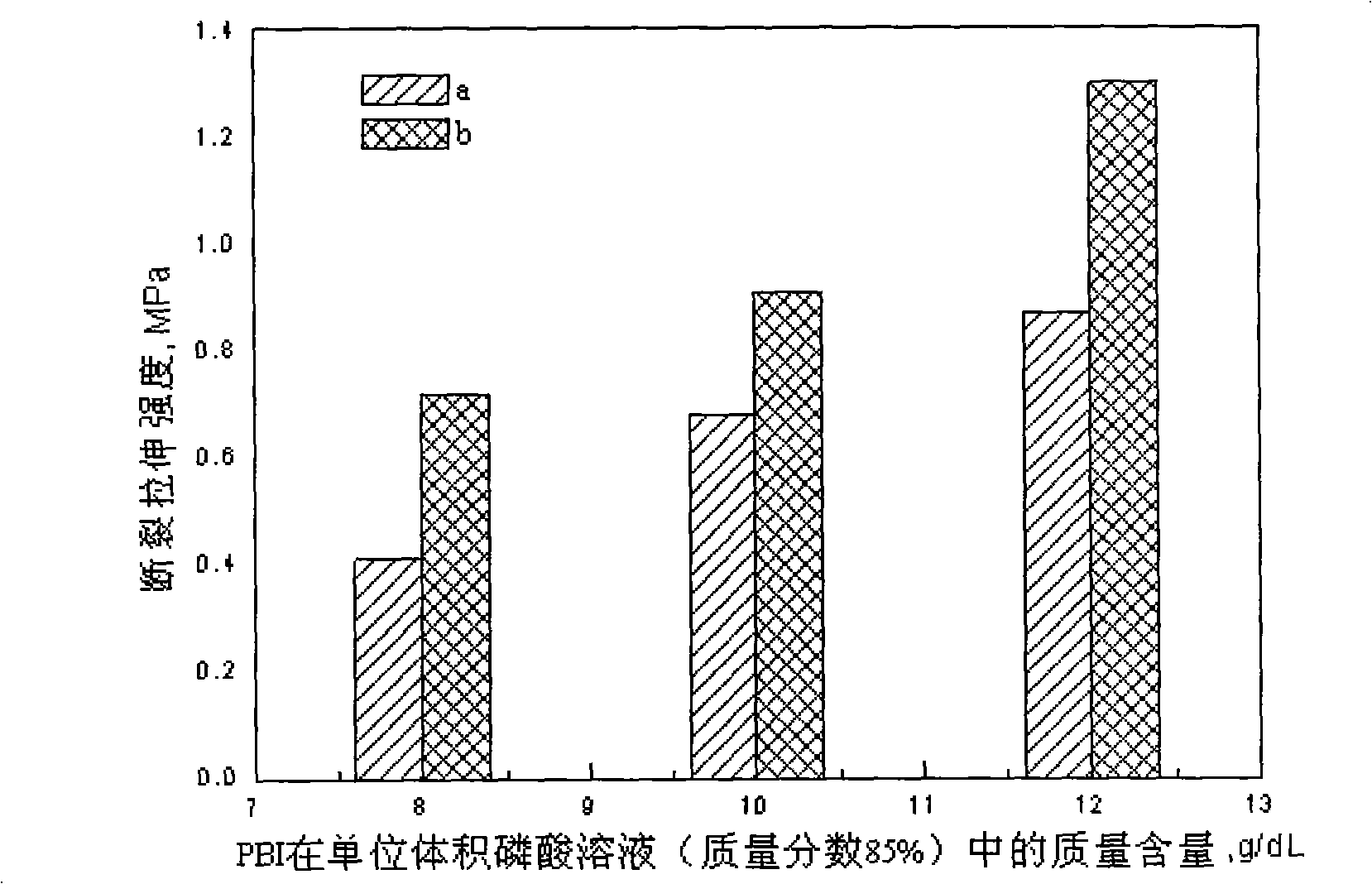

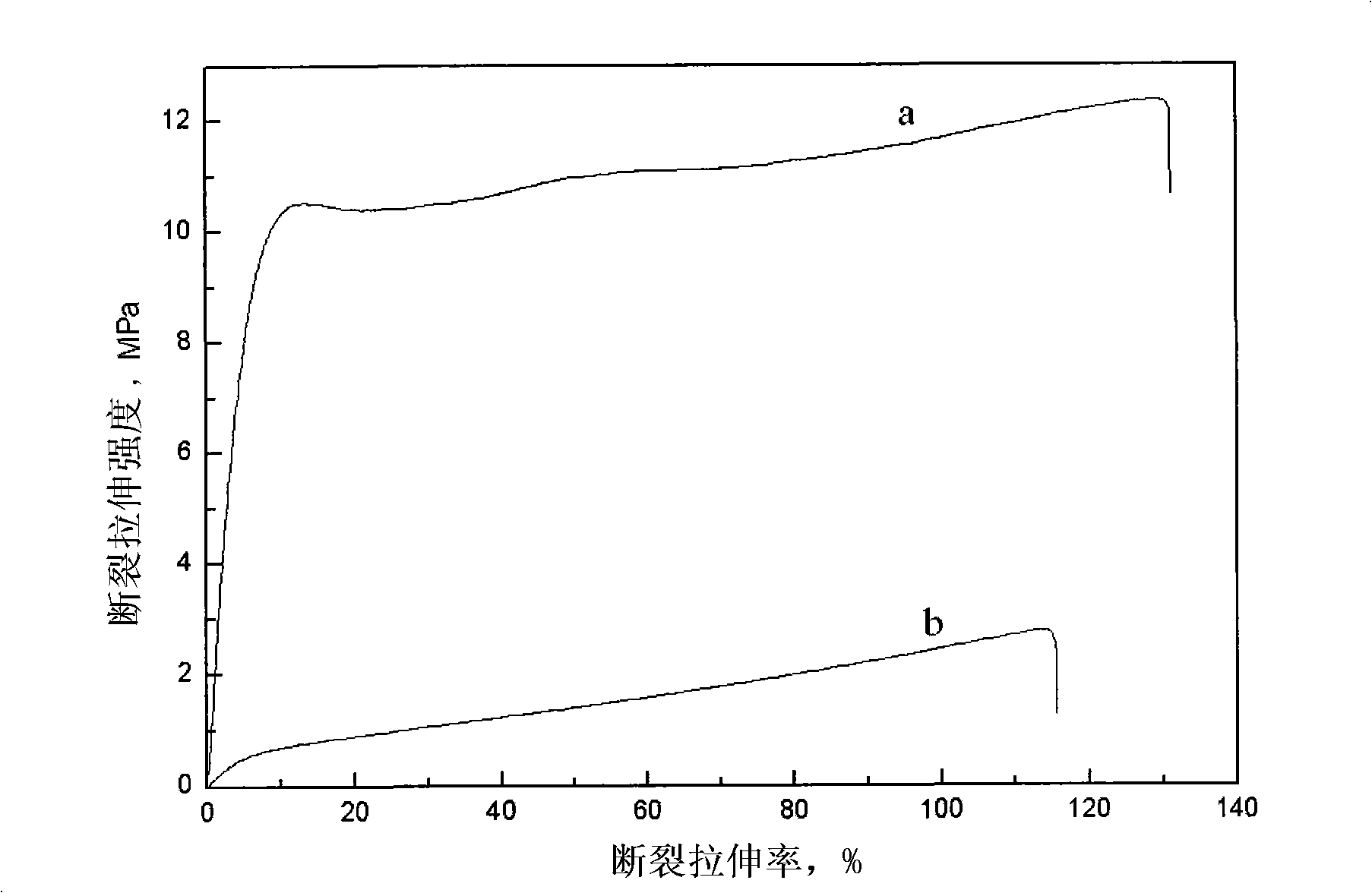

[0051] Mix PBI powder and phosphoric acid solution with a mass concentration of 85%, add 8g of PBI powder per 100mL of 85wt% phosphoric acid solution, and heat to 200°C under nitrogen atmosphere to form a uniform reddish-brown PBI-H 3 PO 4 sol, then PBI-H 3 PO 4 The sol is poured on the flat plate, and the high-temperature PBI-H 3 PO 4 The sol is spread horizontally on the flat plate to form a high temperature PBI-H with a thickness of 0.05mm 3 PO 4 Sol film.

[0052] Will contain high temperature PBI-H 3 PO 4 Put the plate of the sol film horizontally in the refrigerator, freeze at -18±3°C for 24 hours, and then freeze the PBI / H 3 PO 4 The membrane is separated from the plate. Prepare a phosphoric acid solution with a mass concentration of 20%. PBI / H after freezing 3 PO 4 The membrane is completely soaked in the prepared phosphoric acid solution, sealed at room temperature, soaked in a nitrogen atmosphere for 1h, and the solution is mixed with PBI / H 3 PO 4 Intr...

Embodiment 2

[0057] High temperature PBI-H 3 PO 4 The preparation method of the sol film is the same as in Example 1, and the thickness is 0.10mm.

[0058] Will contain high temperature PBI-H 3 PO 4 Put the plate of the sol film horizontally in the refrigerator, freeze at -18±3°C for 28 hours, and then freeze the PBI / H 3 PO 4 The membrane is separated from the plate. Prepare a phosphoric acid solution with a mass concentration of 40%. PBI / H after freezing 3 PO 4 The membrane was completely soaked in the prepared phosphoric acid solution, sealed at room temperature, soaked in a nitrogen atmosphere for 2 hours, and the solution was mixed with PBI / H 3 PO 4 Intramembrane acid balance; then PBI / H 3 PO 4 The membrane was taken out, and the acid on the surface of the membrane was removed with filter paper.

[0059] In PBI / H 3 PO 4 Before the membrane was deformed, the PBI / H 3 PO 4 The membrane was fixed flat between two flat plates, and dried in an oven at 85±5°C for 9 hours; then...

Embodiment 3

[0062] High temperature PBI-H 3 PO 4 The preparation method of the sol film is the same as in Example 1, and the thickness is 0.20mm.

[0063] Will contain high temperature PBI-H 3 PO 4 Put the flat plate of the sol film horizontally in the refrigerator, freeze at -18±3°C for 36 hours, and then freeze the PBI / H 3 PO 4 The membrane is separated from the plate. Prepare a phosphoric acid solution with a mass concentration of 60%. PBI / H after freezing 3 PO 4 The membrane was completely soaked in the prepared phosphoric acid solution, sealed at room temperature, soaked in a nitrogen atmosphere for 3 hours, and the solution was mixed with PBI / H 3 PO 4 Intramembrane acid balance; then PBI / H 3 PO 4 The membrane was taken out, and the acid on the surface of the membrane was removed with filter paper.

[0064] In PBI / H 3 PO 4 Before the membrane was deformed, the PBI / H 3 PO 4 The film was fixed flat between two plates, and dried in an oven at 85±5°C for 10 hours; then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength at break | aaaaa | aaaaa |

| Tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com