Tube-type electric motor manual, electric clutch controller

A technology of electric clutch and tubular motor, which is applied in the direction of clutches, mechanical equipment, door/window protection devices, etc. It can solve the problems of unsuitable, large, and laborious opening and closing of the door, and achieves reduced resistance, fewer parts, and better pulling flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

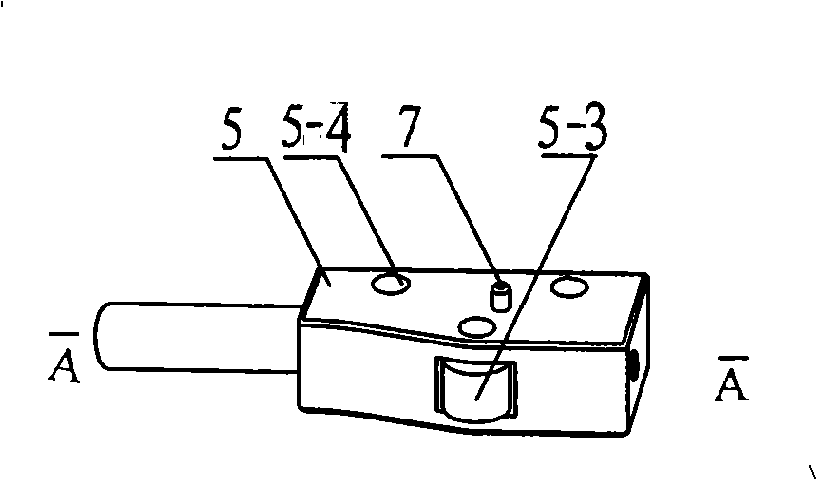

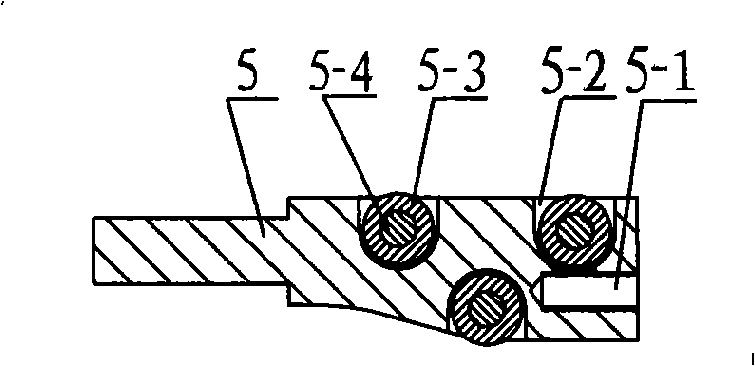

[0016] One end of slide block 5 is cylindrical, and one end is elongated, and the lower end surface of elongated shape has inclined-plane, and on inclined-surface and corresponding upper end surface, there are one or more blind holes that do not communicate, or triangular distribution of three holes. Blind hole 5-2, connects rotatable pulley 5-3 with rivet 5-4 in blind hole, and screw hole 5-1 is arranged on the outer end face of strip shape, is used for fixing the pull bar 10 that has spring 12 rope 11, There is a raised small sliding column 7 in the middle of the strip-shaped upper end face, such as figure 2 , image 3 shown.

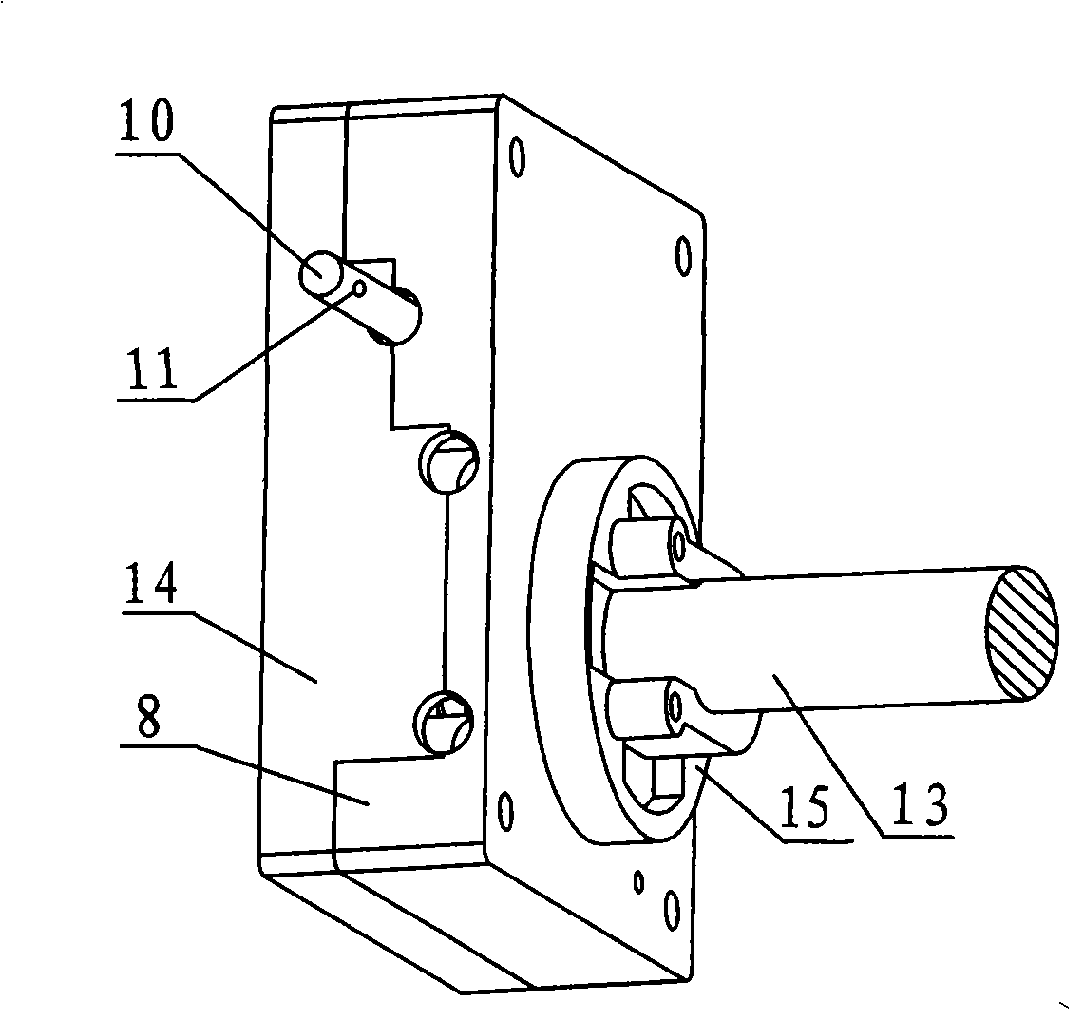

[0017] One end of the torsion spring 3 is fixed on the convex column on the lower surface of the arc rack 4, the torsion spring 3 and the arc rack 4 are set on the rotating shaft 2 on the inner end cover 8, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com