Marine diesel guiding valve type pintle nozzle matching parts

A marine diesel engine and needle valve technology, applied to engine components, mechanical equipment, machines/engines, etc., can solve the problems of corrosion failure at the end of the nozzle hole, affect the fuel atomization effect, and easily block the nozzle nozzle hole, etc., to achieve less emissions , less carbon deposits and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

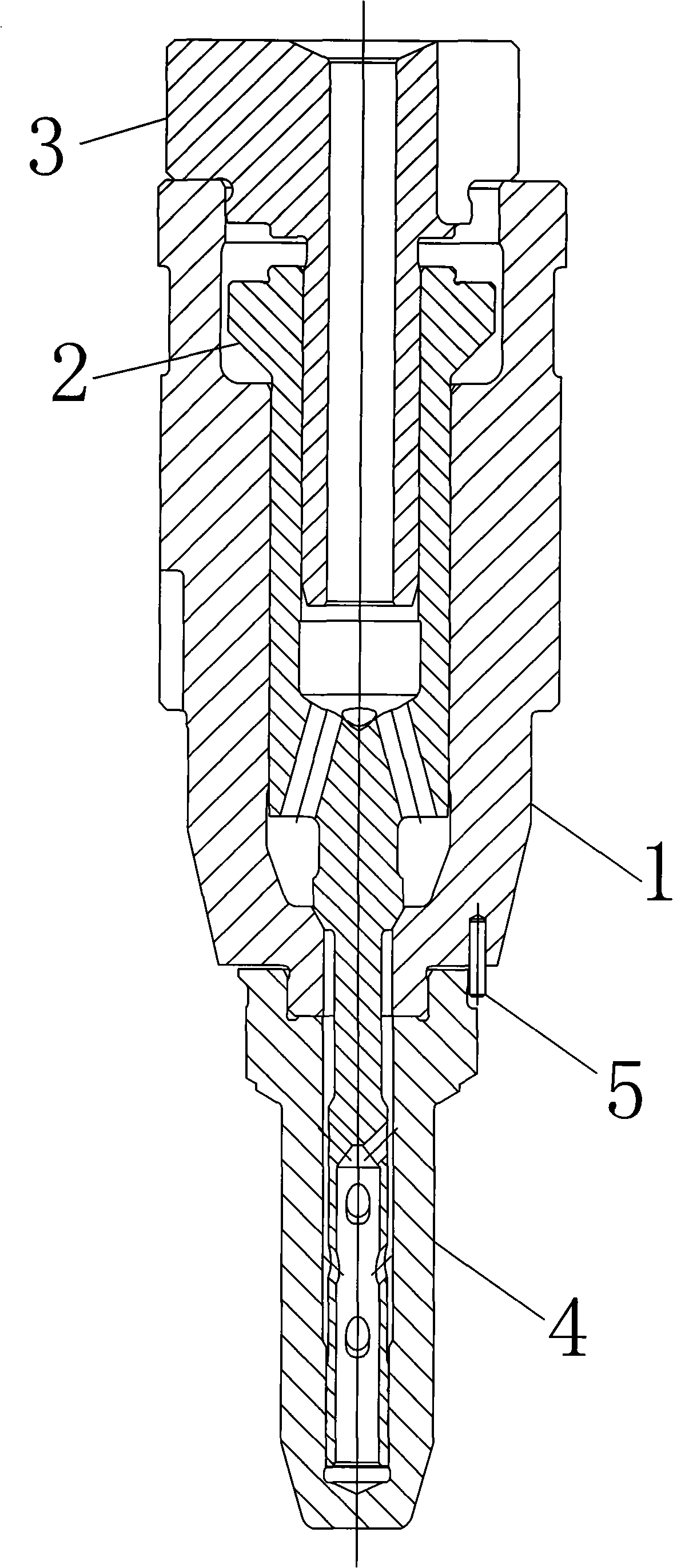

[0012] Structure of the present invention sees figure 1 shown. Marine diesel engine spool type needle valve assembly, including matching needle valve body 1, needle valve 2, thrust seat 3, nozzle 4 and fastener 5, wherein: the inner cavity of needle valve body 1 is ground and fitted with a needle valve 2, and the front part of the needle valve 2 extends into the inner cavity of the nozzle 4 through the front hole of the needle valve body 1; Cooperate with the sliding gap of the nozzle 4, and the boss on the rear of the thrust seat 3 adopts an interference fit with the rear end surface of the needle valve body 1; the installation position of the nozzle 4 is determined by the fastener 5; the needle valve 2 closes the high-pressure oil The road can directly control and close the nozzle 4 nozzle hole, and can reduce the residual fuel carbonizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com