Planar condensing plate

A flat concentrating and flat technology, applied in the field of concentrating panels and solar concentrating panels, can solve the problems of high cost and complicated production process, and achieve the effect of reducing weight, reducing production process and good concentrating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

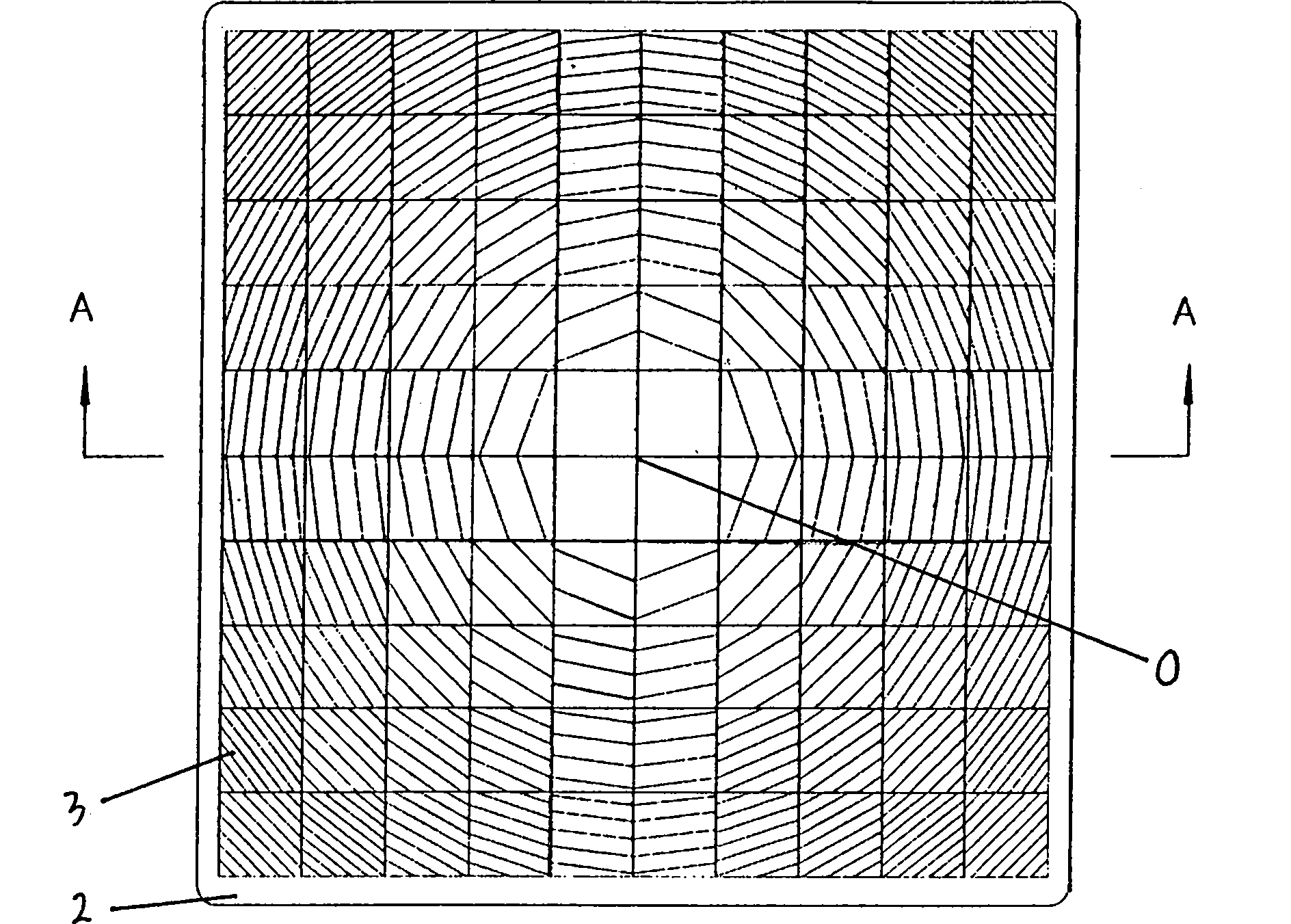

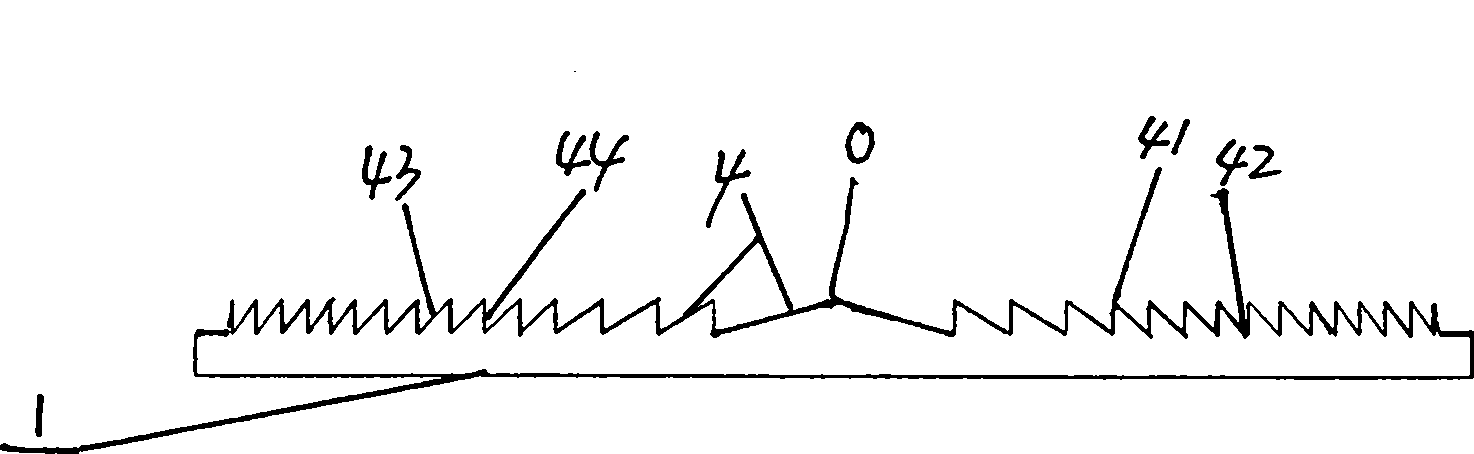

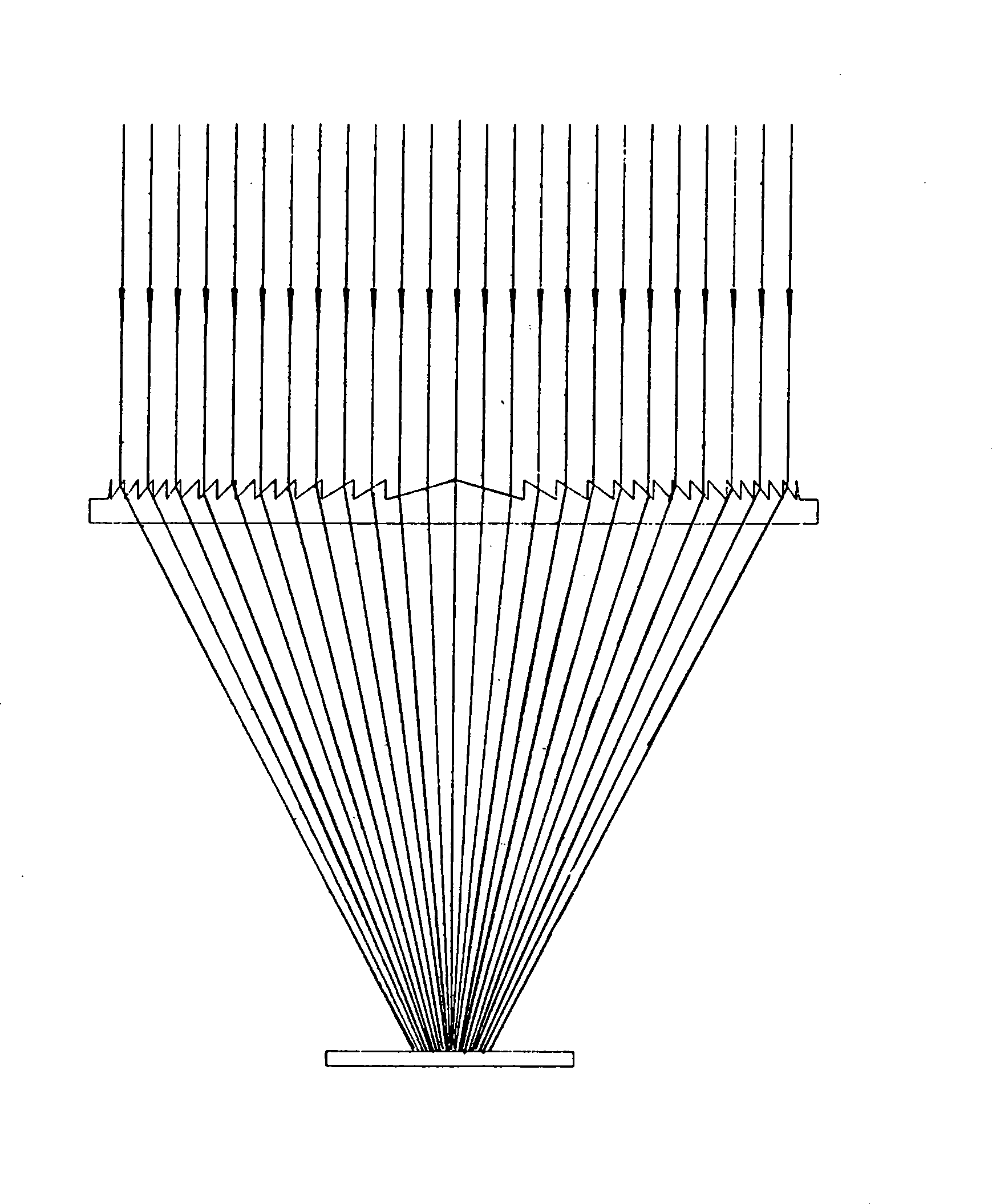

[0020] A flat concentrator, the lower surface 1 is a smooth plane, the upper surface 2 is divided into a plurality of rectangular blocks 3, and at least one slope 4 is arranged in each rectangular block 3, and the tops 41 of the slopes are all close to the center O of the upper surface. The slope bottoms 42 are all away from the center O of the upper surface. In this way, after the sunlight is refracted by the slope, it will gather at the vertical line at the center of the upper surface without diverging the light.

[0021] The four rectangular blocks 3 next to the center O of the upper surface have only one slope 4 . Other rectangular blocks 3 are provided with two or more than two slopes 4, and the top 41 and bottom 42 of the slope 4 in the same rectangular block 3 are straight lines and parallel to each other, and the top 41 of the slope 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com