Method for removal of unburned carbon in fly ash

一种未燃碳、飞灰的技术,应用在化学仪器和方法、固体废物的清除、具有旋转搅拌装置的混合机等方向,能够解决堵塞飞灰供给管、不能充分混合等问题,达到设置面积减少、持续稳定设备成本、经济性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

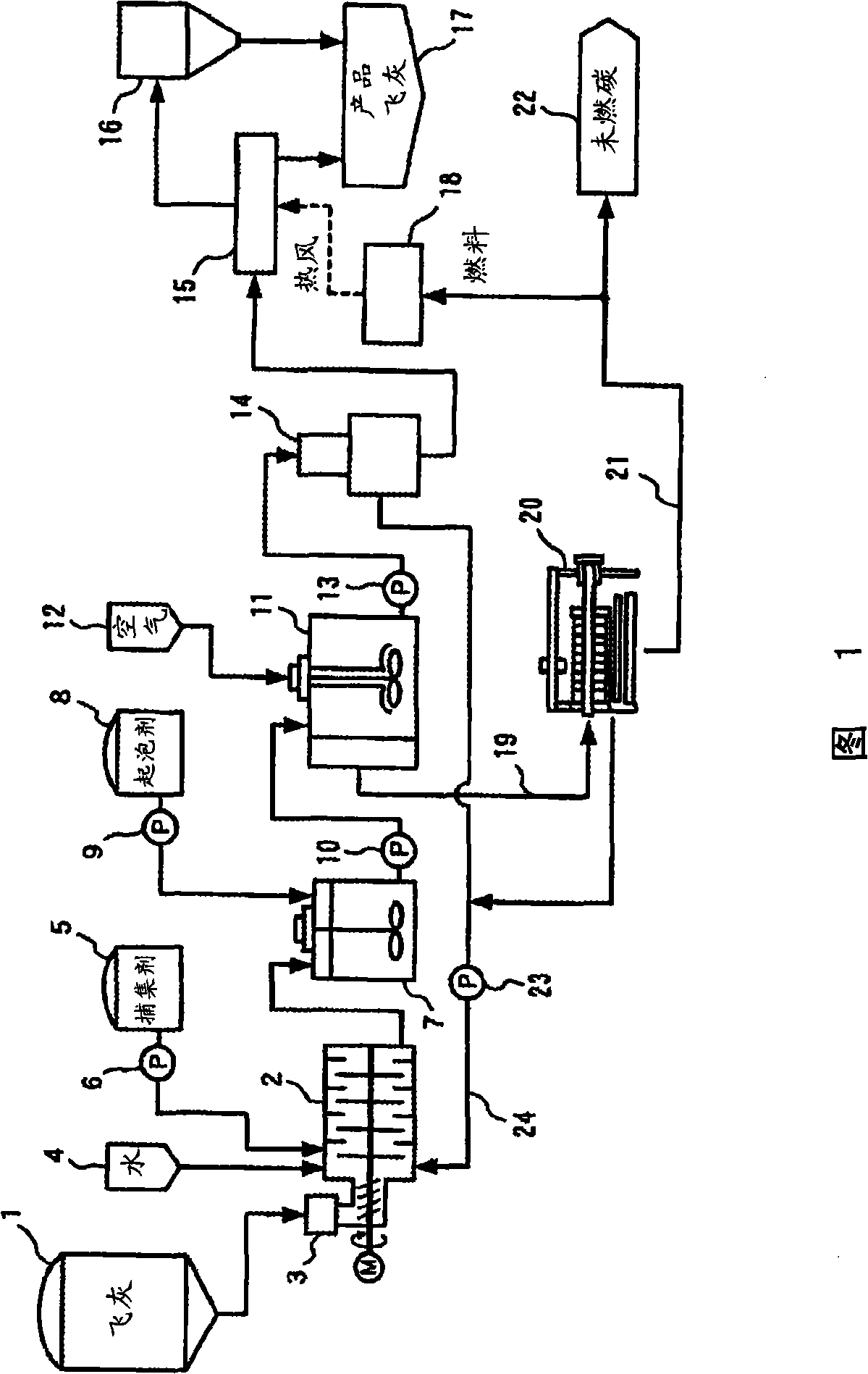

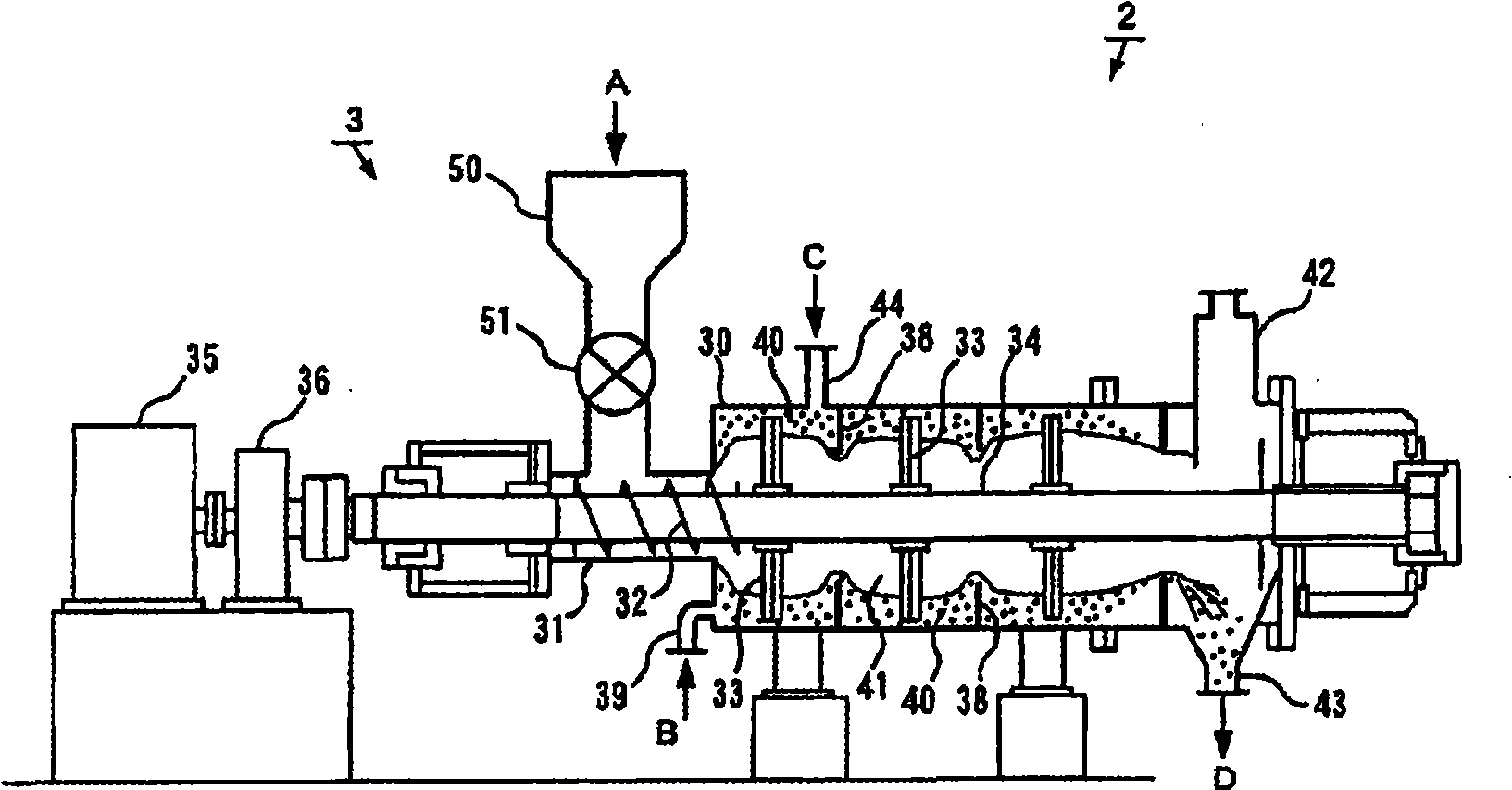

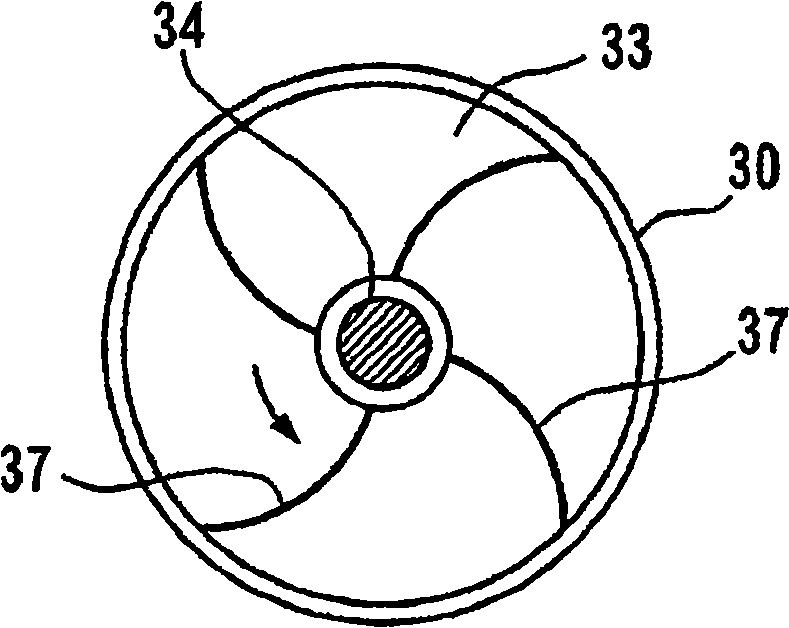

[0029] An embodiment of the present invention will be described based on FIG. 1 . Fig. 1 shows a system diagram of an equipment system for practicing the present invention.

[0030] This system is mainly produced by adding a collector to the hybrid mixer (hybrid mixer) 2 that imparts high shear force while preparing a slurry containing fly ash and water, and adding a foaming agent to the slurry produced by the above-mentioned hybrid mixer 2 Air bubbles, a flotation machine 11 for attaching and floating unburned carbon in the fly ash for separation, a solid-liquid separator 14 for separating and recovering the fly ash from the sediment separated by the above-mentioned flotation machine 11, and the same A dehydrator 20 is configured to dehydrate the floating matter separated by the above-mentioned flotation machine 11 and recover unburned carbon.

[0031] The devices constituting the system will be specifically described below.

[0032] The fly ash tank 1 is used to store and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com