Automatic even material feeding device

A feeding device and uniform material distribution technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve problems affecting incineration quality, air quality, flue gas purification system, etc., and achieve a wide range of adaptation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

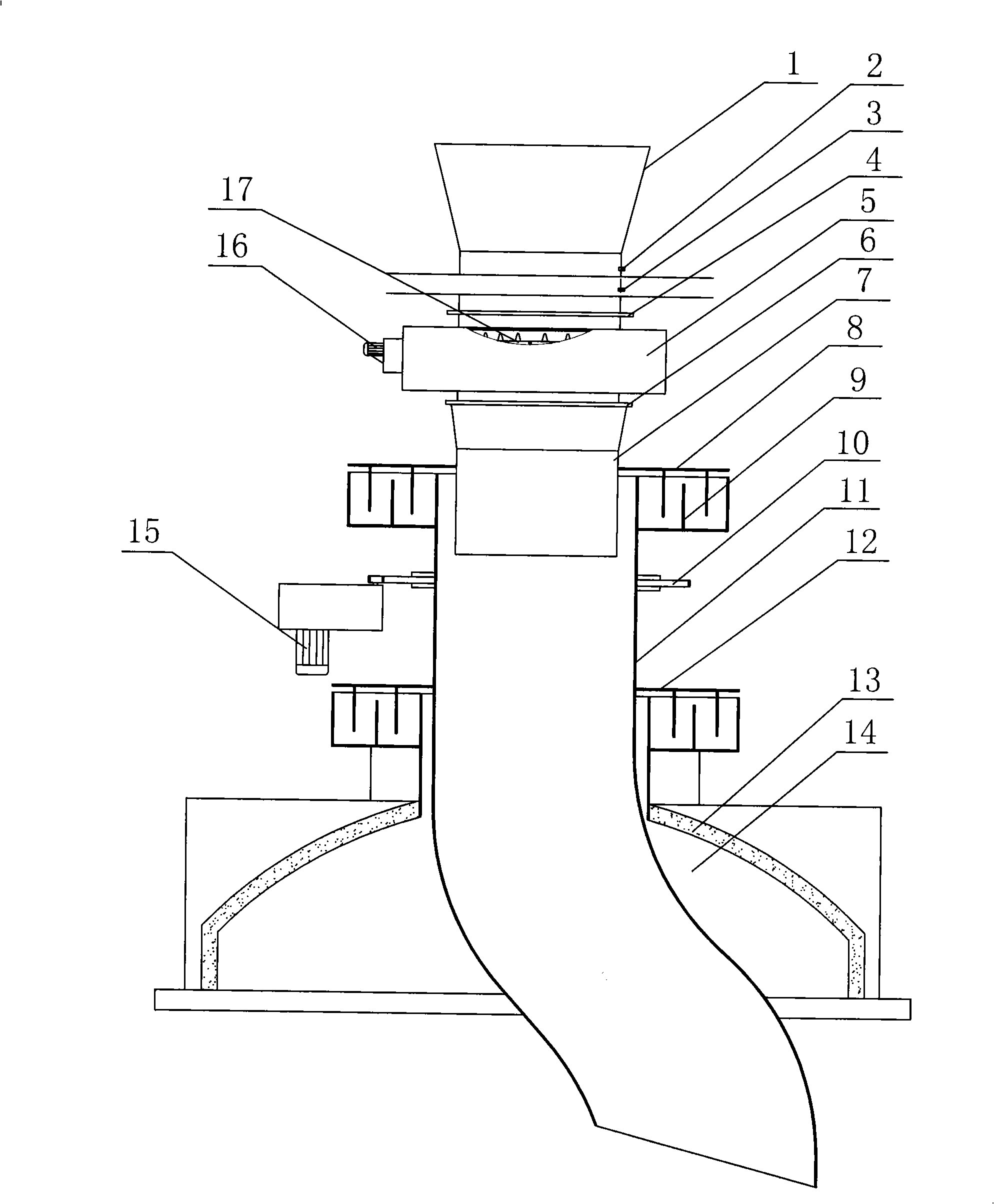

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] Such as figure 1 Shown is a preferred embodiment of the automatic uniform feeder of the present invention.

[0023] Sealing device (mainly vertical silo 1, which is welded by ordinary carbon steel, high proximity switch 2 is fixed at three quarters of the height on the wall of vertical silo 1, and low proximity switch 3 is fixed on the height of vertical silo wall A quarter of the composition) is connected with the double roller feeder 5 through the flange 4.

[0024] The double-roller feeder 5 is composed of a driving mechanism 16 and a feeding roller 17. The driving mechanism 16 adopts a frequency conversion motor to realize stepless speed regulation. The irregular arrangement of conical protrusions on the feeding roller 17 can not only play the role of feeding , and can destroy plastic bags. The double-roller feeder 5 is connected with the interface 7 of the sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com