Conversion of methane to higher hydrocarbon

A technology for methane, hydrocarbon feedstocks, used in chemical instruments and methods, chemical/physical processes, condensation with dehydrogenated hydrocarbons to produce hydrocarbons, etc., can solve the problem of not being able to reliably provide continuous control of the location and dissipation of heat generation and methods, reducing the efficiency of the reactor system, inefficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

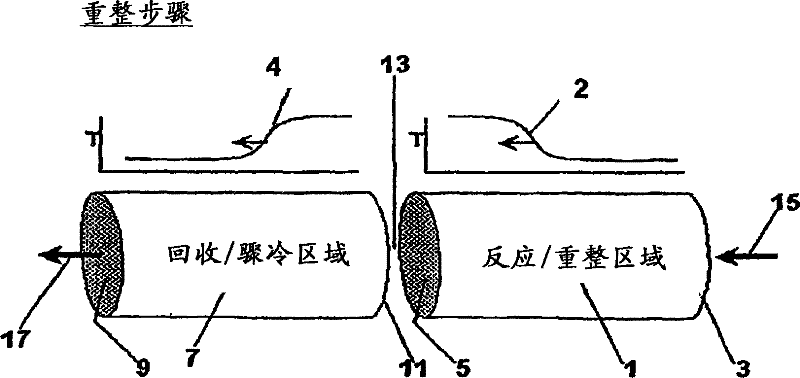

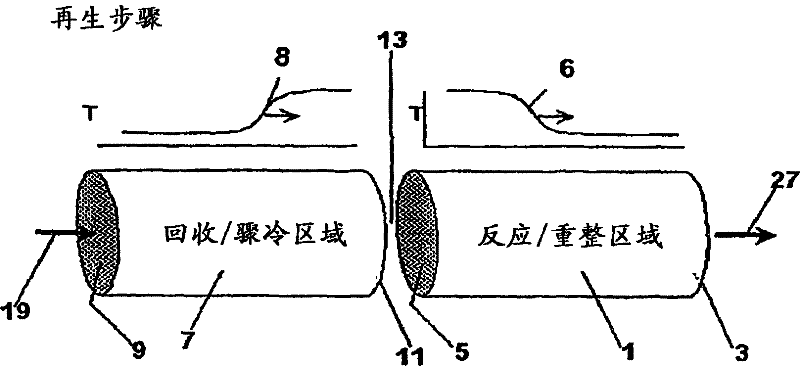

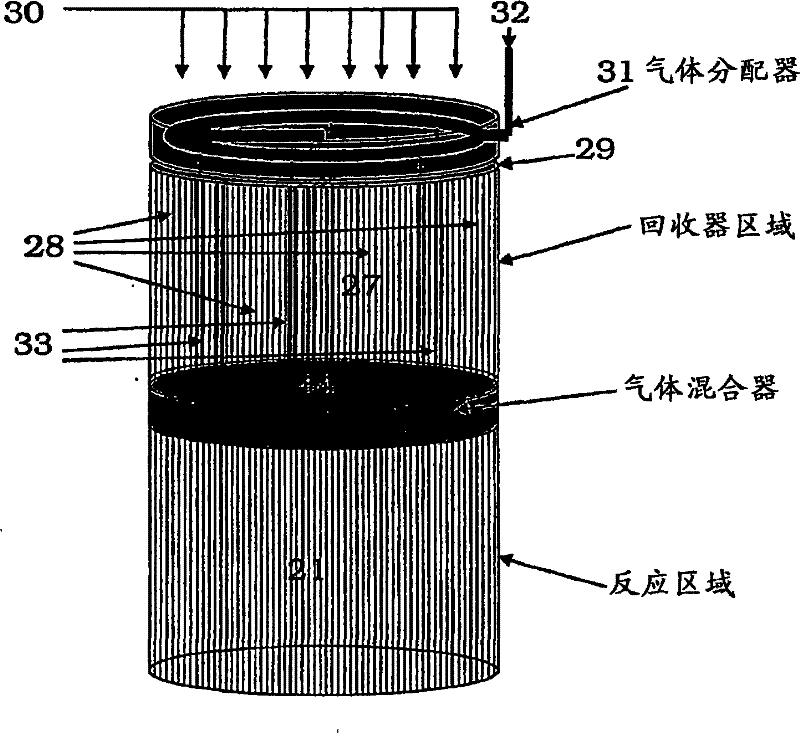

[0097] The following example is intended to illustrate an exemplary embodiment and method only and is not meant to limit the scope of the invention. Methane is converted to acetylene in a pair of reactor systems, each according to a brief description Figure 5 installed, suitably valved, so that one reactor system performs the regeneration step while the other reactor system performs the pyrolysis step. Some embodiments may also include more than one pair of more reactor systems, eg, multiple reactor systems, each operating in a staged timed arrangement, so that the overall process is substantially continuous. The reactor system includes at least a first reactor / recoverer (102), a mixer or mixing zone (109), and a second reactor / reforming zone (101).

[0098] Both the reforming (101) and recycling (102) reactor zones consist of extruded ceramic honeycomb monoliths that are three-dimensionally stacked to fill the reactor zone volume. The entire reactor system is about 10 ft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com