Composite curing agent and epoxy resin composition prepared from composite curing agent

A composite curing agent and epoxy resin technology, which is applied in the field of epoxy resin materials, can solve the problems of low production efficiency, material performance degradation, and high preparation process requirements, and achieve high production efficiency, avoid large reaction heat release, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

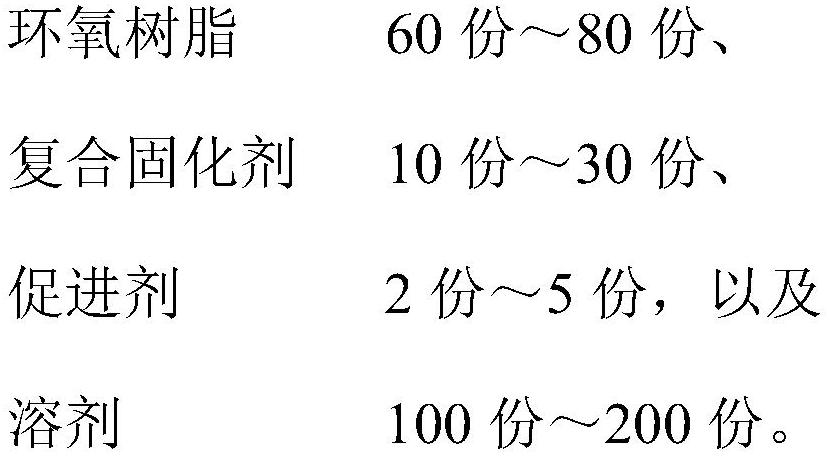

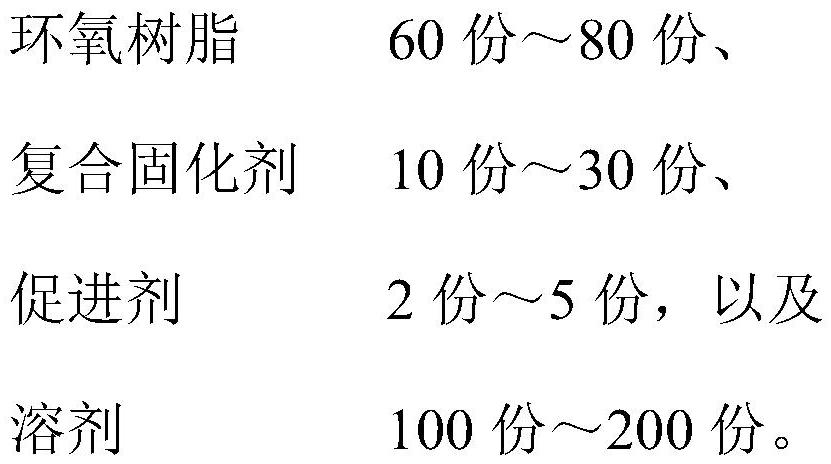

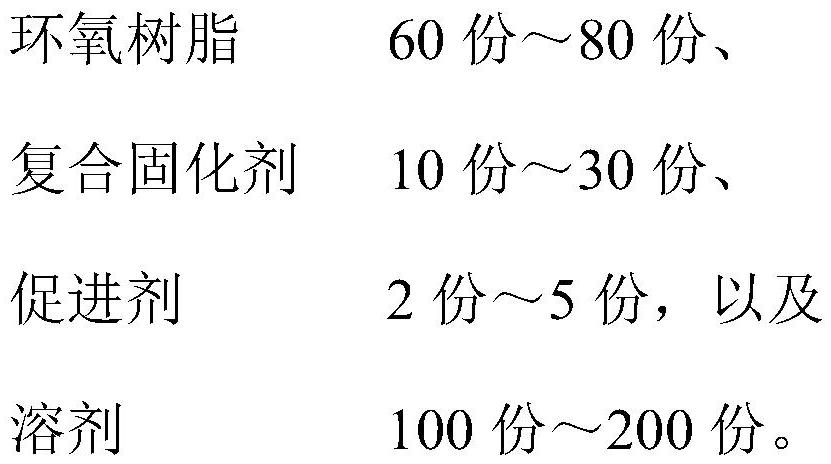

Method used

Image

Examples

Embodiment 1

[0047] Add 9 parts of ethylenediamine modified curing agent, 3 parts of adipic acid dihydrazide, 3 parts of boron trichloride-octylamine complex, 3 parts of 2-methylimidazolium, and 100 parts of propylene glycol methyl ether solvent into Stir the batching bottle with a stirrer until it is completely dissolved. After completely dissolving, add 60 parts of bisphenol A epoxy resin and 1 part of alkylene glycidyl ether and stir evenly to prepare a glue.

Embodiment 2

[0049] Add 9 parts of ethylenediamine modified curing agent, 3 parts of adipic acid dihydrazide, 3 parts of boron trichloride-octylamine complex, 3 parts of 2-methylimidazolium, and 100 parts of propylene glycol methyl ether solvent into Stir the batching bottle with a stirrer until it is completely dissolved. After completely dissolving, add 70 parts of bisphenol A epoxy resin and 1 part of alkylene glycidyl ether and stir evenly to prepare a glue.

Embodiment 3

[0051] Add 9 parts of ethylenediamine modified curing agent, 3 parts of adipic acid dihydrazide, 3 parts of boron trichloride-octylamine complex, 3 parts of 2-methylimidazolium, and 100 parts of propylene glycol methyl ether solvent into Stir the batching bottle with a stirrer until it is completely dissolved, add 80 parts of bisphenol A epoxy resin and 1 part of alkylene glycidyl ether after complete dissolution, and stir evenly to prepare a glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com