Novel sodium-method desulfurizing tower

A technology of desulfurization tower and sodium method, which is applied in the field of environmental protection, can solve the problems of large absorbent consumption, large floor area, and low desulfurization efficiency, so as to reduce floor space and equipment investment, and make up for the shortage of market supply , High desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

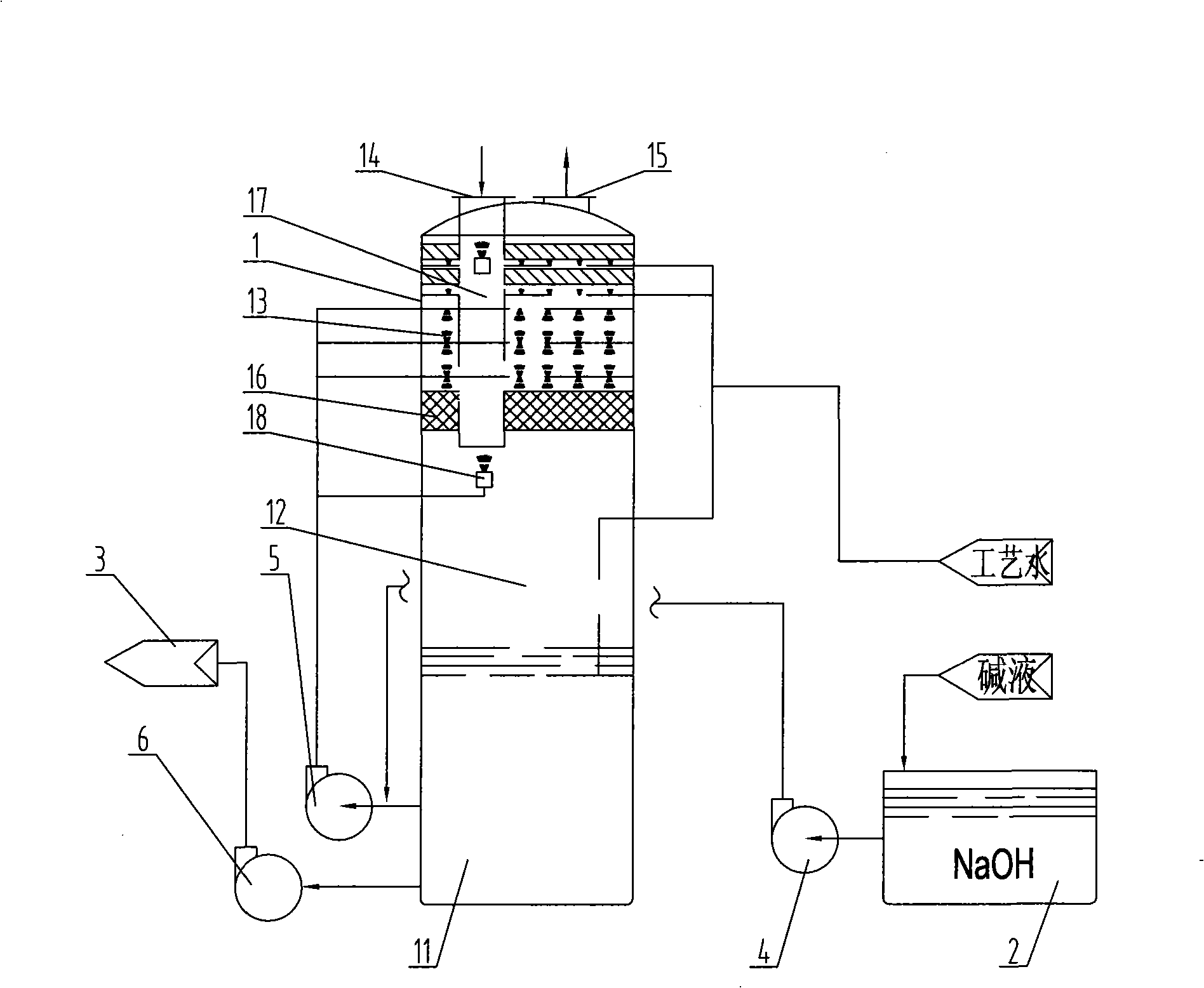

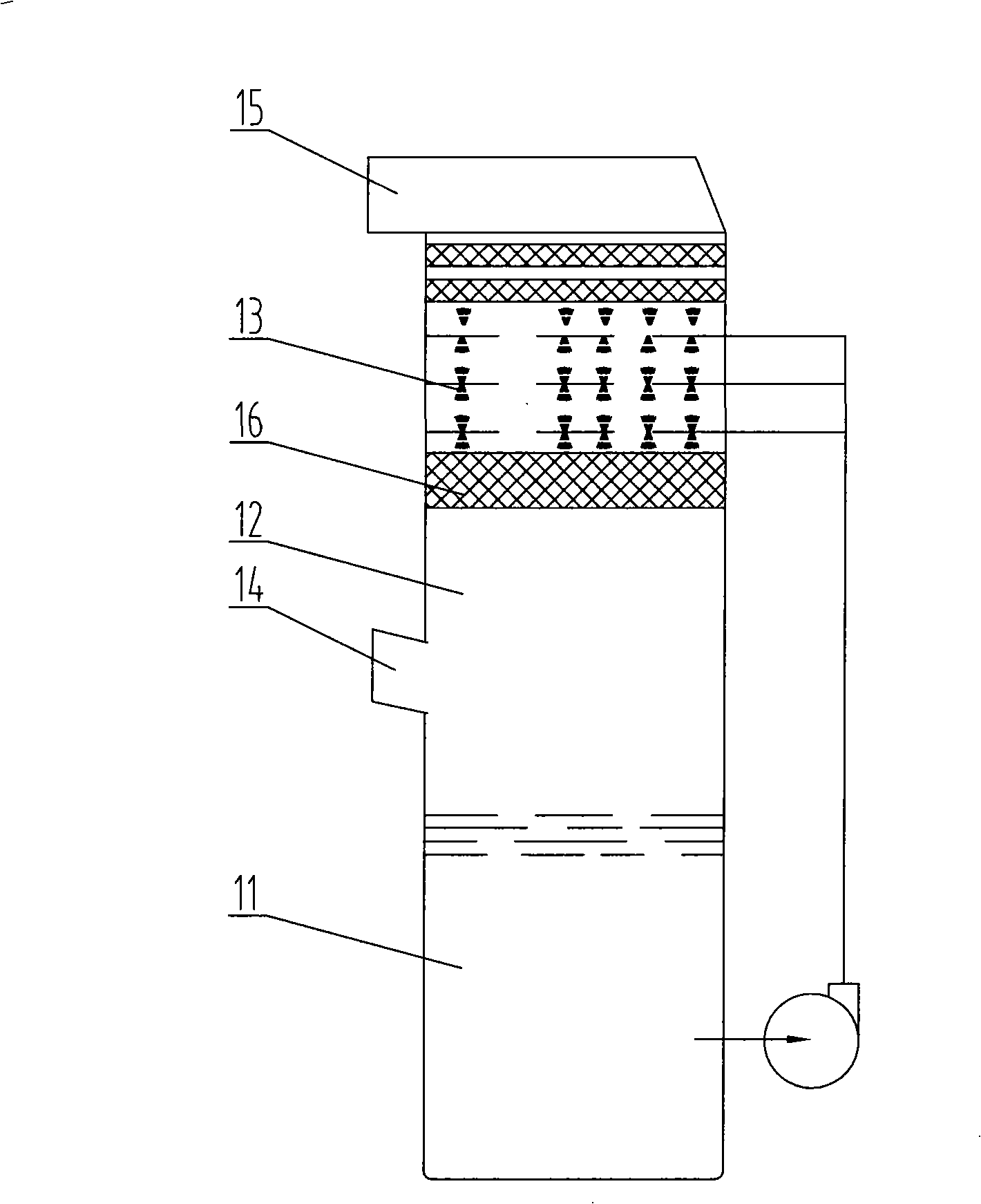

[0019] refer to figure 1 , a new type of sodium desulfurization tower, including an absorption tower 1, a NaOH storage tank 2, a final product decrystallization or biological treatment system 3, the bottom of the absorption tower 1 is an oxidation slurry pool 11, the middle part is a gas-liquid contact zone 12, and the upper part is a Spray area 13, the bottom suction port of oxidation slurry pool 11 is connected to spray area 13 by slurry circulation pump 5, NaOH absorbent is stored in the described NaOH storage tank 2, and is connected to the slurry circulation pump 5 by delivery pump 4 The inlet and the oxidation slurry tank 11 are connected to the final product decrystallization or biological treatment system 3 through the discharge pump 6, and the absorption tower 1 is provided with a raw flue gas inlet 14 and a clean flue gas outlet 15. The spray area 13 is provided with 1-5 spray layers. The circulating slurry is diffused through the nozzle in the spray layer to increa...

Embodiment 2

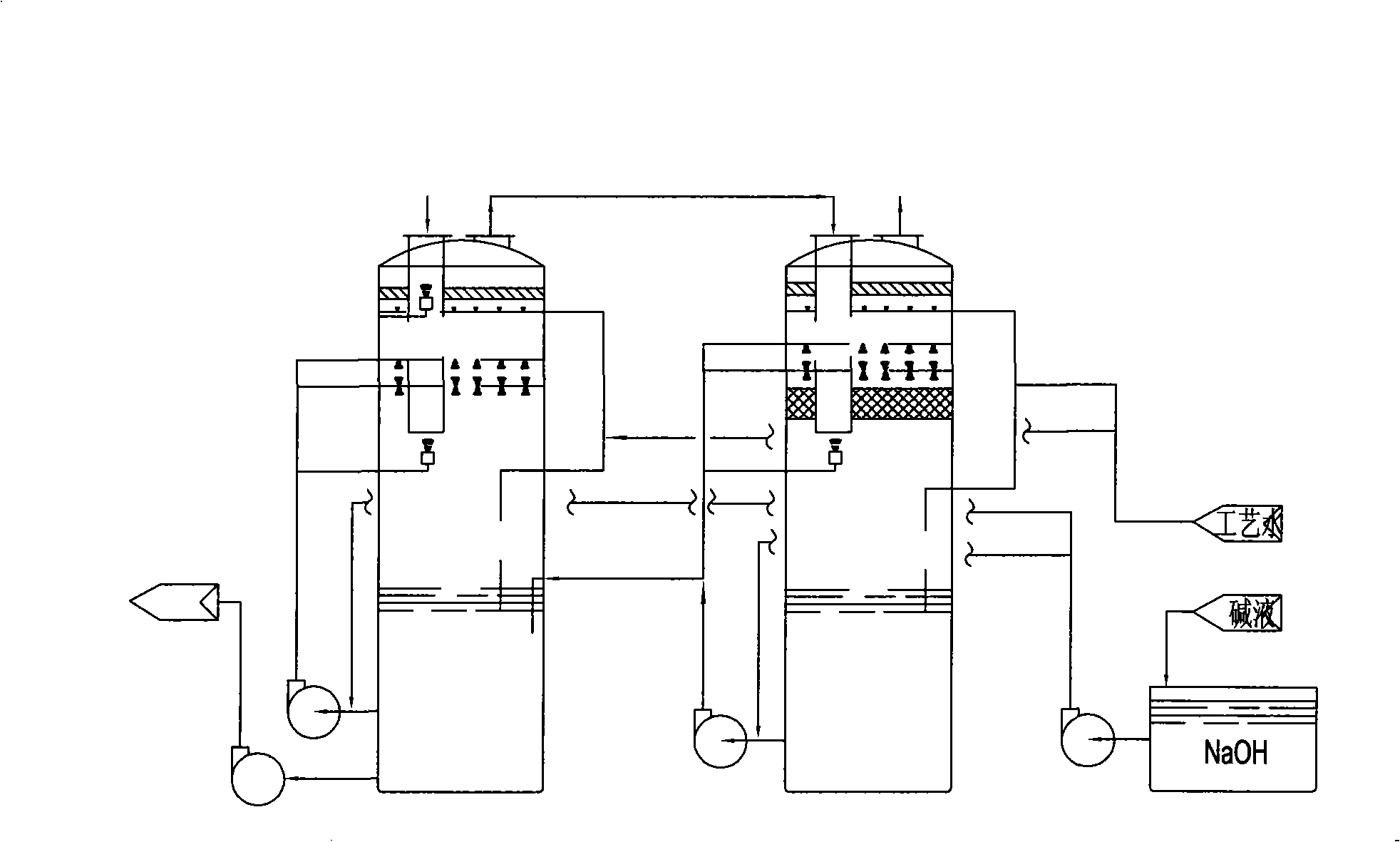

[0025] refer to figure 2 , adopted 2 absorption towers 1 in the present embodiment, is double absorption tower structure, can not be provided with packing layer in primary absorption tower when adopting double absorption tower, and secondary absorption tower does not need equipment such as pre-spray device, simplifies The structure of a single absorption tower improves the absorption effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com