Waterproof type rock swelling ammonium nitrate explosive and preparation technique thereof

A technology of rock-expanded ammonium nitrate and waterproof type, which is applied in the direction of explosives, etc. It can solve the problems of inability to apply waterproof expanded ammonium nitrate explosive formula and technology, poor coating effect of waterproof materials, and water-proof discount, so as to improve charge efficiency. , easy to charge and pack, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

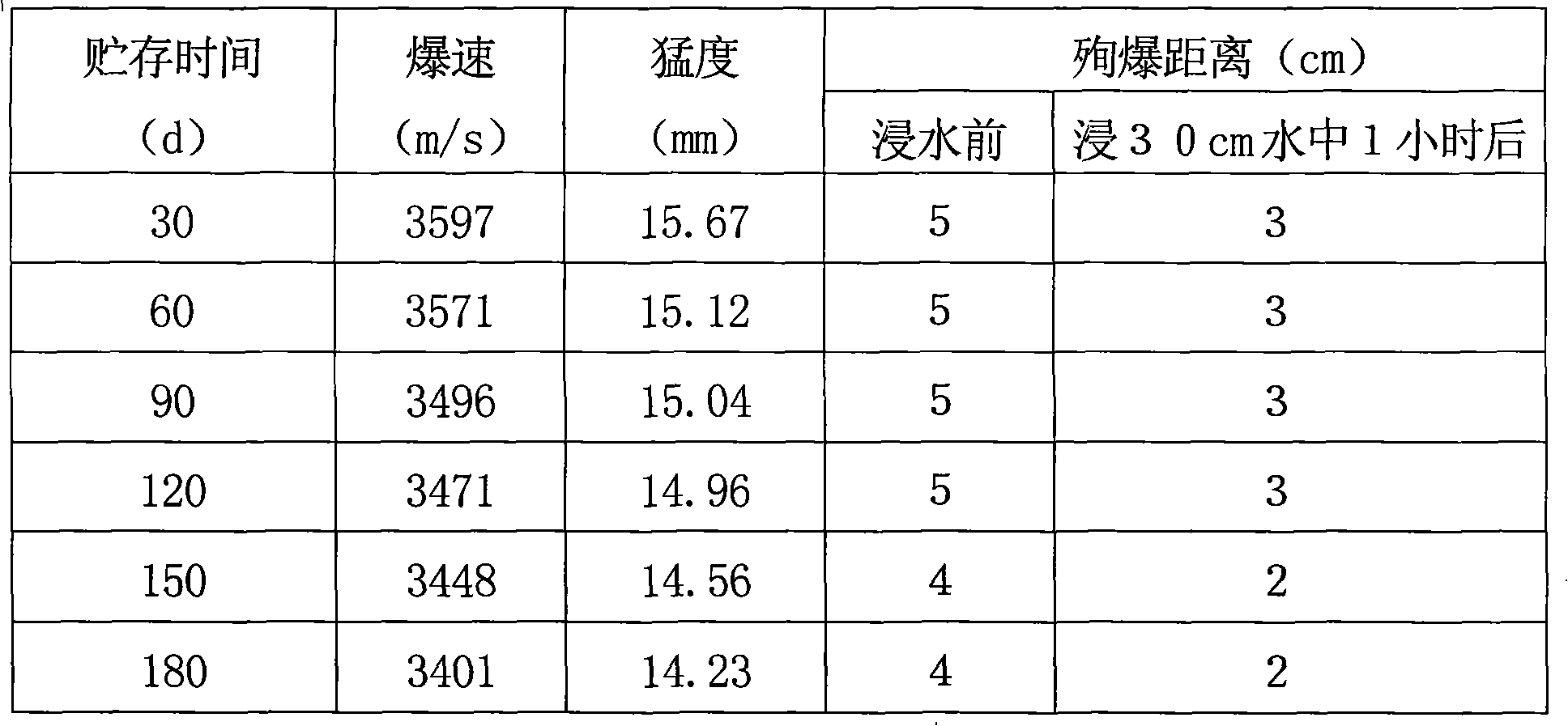

Embodiment 1

[0024] Add 9.6% hot water to the water phase melting tank, then add 90.4% ammonium nitrate, heat up to make it fully dissolve and reach the process temperature of 125°C to 135°C, expand and crystallize the prepared solution to obtain expanded ammonium nitrate for use . Dry the wood powder for later use. Take 62.5% special grease for explosives and 32.5% vaseline, heat and fully melt and mix, when the temperature reaches 80°C, add 5% stearylamine, melt and mix, and heat to 120°C to obtain a composite oil phase. According to the ratio of 92% expanded ammonium nitrate, 4% wood flour and 4% composite oil phase, the three components are measured separately, and then the three materials are mixed continuously. The mixing temperature is 50 ° C, and the waterproof rock expanded ammonium nitrate explosive is produced continuously. . Explosive performance and waterproof performance: the detonation distance is 4cm3 / 3, the detonation velocity is 3571m / s, and the intensity is 15.62mm. A...

Embodiment 2

[0026] Add 9.6% hot water to the water phase melting tank, then add 90.4% ammonium nitrate, heat up to make it fully dissolve and reach the process temperature of 125°C to 135°C, expand and crystallize the prepared solution to obtain expanded ammonium nitrate for use . Dry the coal powder for later use. Take 10% special grease for explosives and 85% vaseline, heat and fully melt and mix, when the temperature reaches 80°C, add 5% polyacrylamide, melt and mix, and heat up to 110°C to obtain a composite oil phase. According to the ratio of 94% expanded ammonium nitrate, 3% wood flour and 3% composite oil phase, the three components are measured separately, and then the three materials are mixed continuously. The mixing temperature is 90°C, and the waterproof rock expanded ammonium nitrate explosive is produced continuously. . Explosive performance and waterproof performance: the detonation distance is 5cm3 / 3, the detonation velocity is 3906m / s, and the intensity is 15.34mm. Af...

Embodiment 3

[0028] Add 9.6% hot water to the water phase melting tank, then add 90.4% ammonium nitrate, heat up to make it fully dissolve and reach the process temperature of 125°C to 135°C, expand and crystallize the prepared solution to obtain expanded ammonium nitrate for use . Dry the wood powder for later use. Take 62.5% special grease for explosives, 7.5% engine oil and 25% petrolatum and heat to fully melt and mix. When the temperature reaches 100°C, add 5% stearylamine to melt and mix and heat to 120°C to obtain a composite oil phase. The three components of 91% expanded ammonium nitrate, 4.5% wood powder and 4.5% composite oil phase are mixed continuously, the mixing temperature is 80°C, and the waterproof rock expanded ammonium nitrate explosive is obtained by continuous discharge. Explosive performance and waterproof performance: the detonation distance is 4cm3 / 3, the detonation velocity is 3401m / s, and the intensity is 14.4mm. After the drug roll is immersed in water for 30c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com