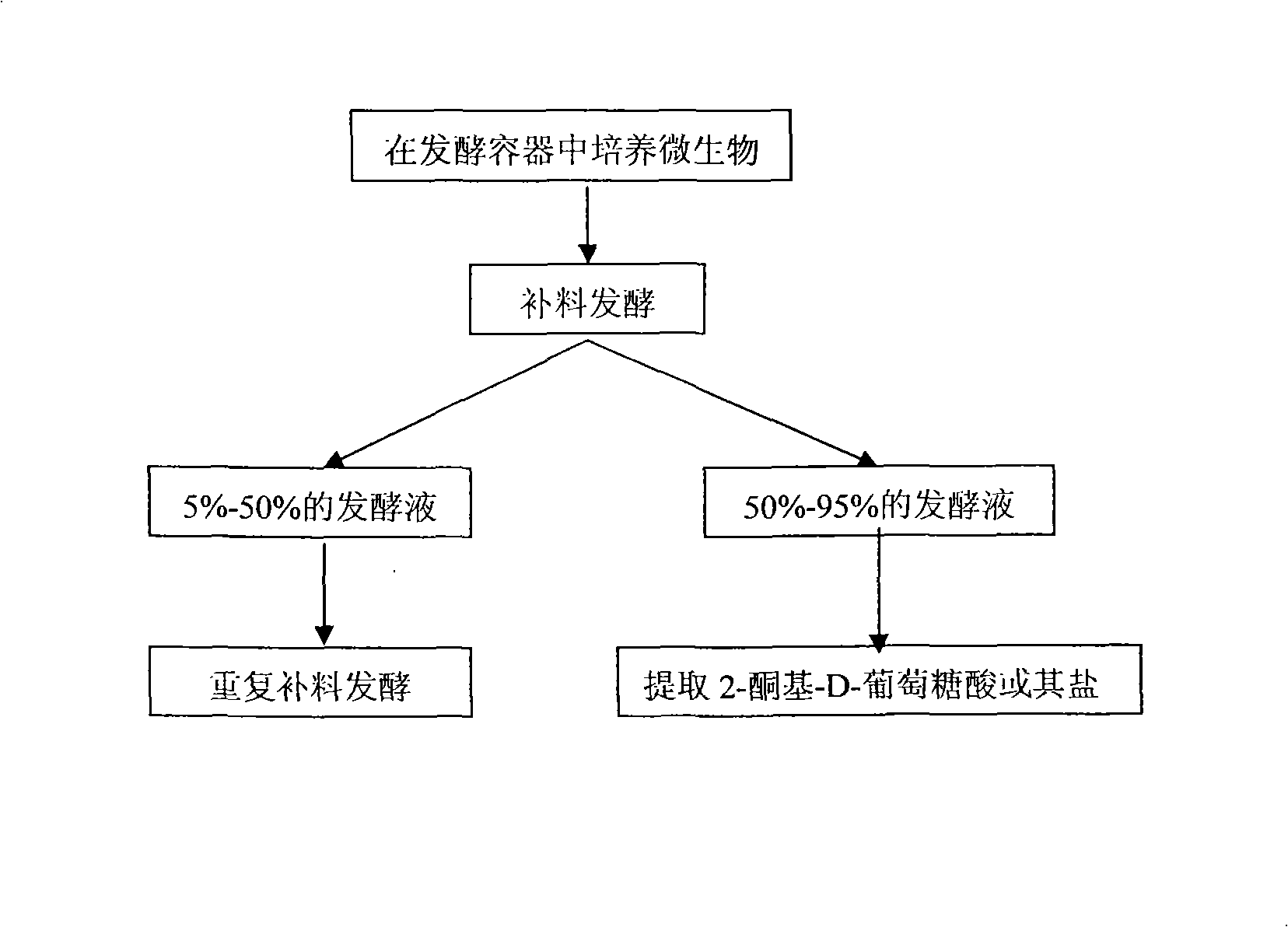

2-keto-d-gluconic acid semicontinuous fermentation process

A fermentation process, gluconic acid technology, applied in the directions of fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of low fermentation yield and unstable product quality, and achieve improved fermentation yield, easy automation, and high equipment utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The seeds were cultured in a 5L self-controlled fermenter. Put the bacterial suspension of Pseudomonas fluorescens K1005 into 2.0L containing 2.0% glucose, 1.0% corn steep liquor, 0.2% urea, 0.2% KH 2 PO 4 , 0.05% MgSO 4 ·7H 2 O, 0.25% light CaCO 3 In the seed medium (pH 7.0 before sterilization), the stirring speed was controlled to 400 rpm, the tank temperature was 33° C., the tank pressure was 0.030 MPa, and the ventilation rate was 0.5 v / v / m for 20 h.

[0018] Semi-continuous fermentation adopts 50L automatic control fermenter. The composition of the fermentation medium was: 16.2% starch hydrolyzed sugar, 1.5% corn steep liquor and 4.5% light CaCO 3 (pH 6.7 before sterilization). Put the above-mentioned cultured seed solution into 20L fermentation medium, control the stirring speed at 400rpm, tank temperature at 33°C, tank pressure at 0.030MPa, and ventilation rate at 0.7v / v / m for 24h, and then supplemented with 2.0L / h An additional 20 L of fermentation mediu...

Embodiment 2

[0020] Seed culture is the same as in Example 1.

[0021] The composition of the fermentation medium was: 18.0% starch hydrolyzed sugar, 1.5% corn steep liquor and 5.0% light CaCO 3 (pH 6.7 before sterilization). Put the seed liquid into 20L fermentation medium, control the stirring speed at 400rpm, tank temperature at 33°C, tank pressure at 0.030MPa, and ventilation rate at 1.0v / v / m for 30h, and then feed at a feeding rate of 2.0L / h An additional 20 L of fermentation medium. After feeding is finished, quickly drain about 20L of fermentation broth, and repeat the feeding operation above. This was repeated 5 times, and it took a total of about 82 hours to produce 21052.6 g of 2-keto-D-gluconic acid. The concentration of 2-keto-D-gluconic acid in the fermentation broth was 178.4 g / L, and the residual glucose in the fermentation broth The average is 0.041%. Calculated according to the above results, the average fermentation conversion rate (mol / mol) is 90.43%, and the average...

Embodiment 3

[0023] Seed culture is the same as in Example 1.

[0024] The composition of fermentation medium is with embodiment 2. Put the seed solution into 20L of fermentation medium, control the stirring speed at 400rpm, the tank temperature at 34°C, the tank pressure at 0.020MPa, and the ventilation rate at 1.0v / v / m for 30h, and then feed at a feeding rate of 2.2L / h An additional 20 L of fermentation medium. After feeding is finished, quickly drain about 20L of fermentation broth, and repeat the feeding operation above. This was repeated 5 times, and it took a total of about 78 hours to produce 20944.9g of 2-keto-D-gluconic acid. The concentration of 2-keto-D-gluconic acid in the fermentation broth was 175.8g / L, and the residual glucose in the fermentation broth The average is 0.103%. Calculated according to the above results, the average fermentation conversion rate (mol / mol) is 89.97%, and the average fermentation yield is about 5.37g / L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com