Blower fan and washing and drying integrated machine

A fan and the technology of the fan, applied in the field of the fan and the integrated washing and drying machine with the fan, can solve the problems of large wind pressure loss, low drying efficiency, and less air circulation times of the washing drum in the dehumidification and drying system, and achieve low cost , easy processing, the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

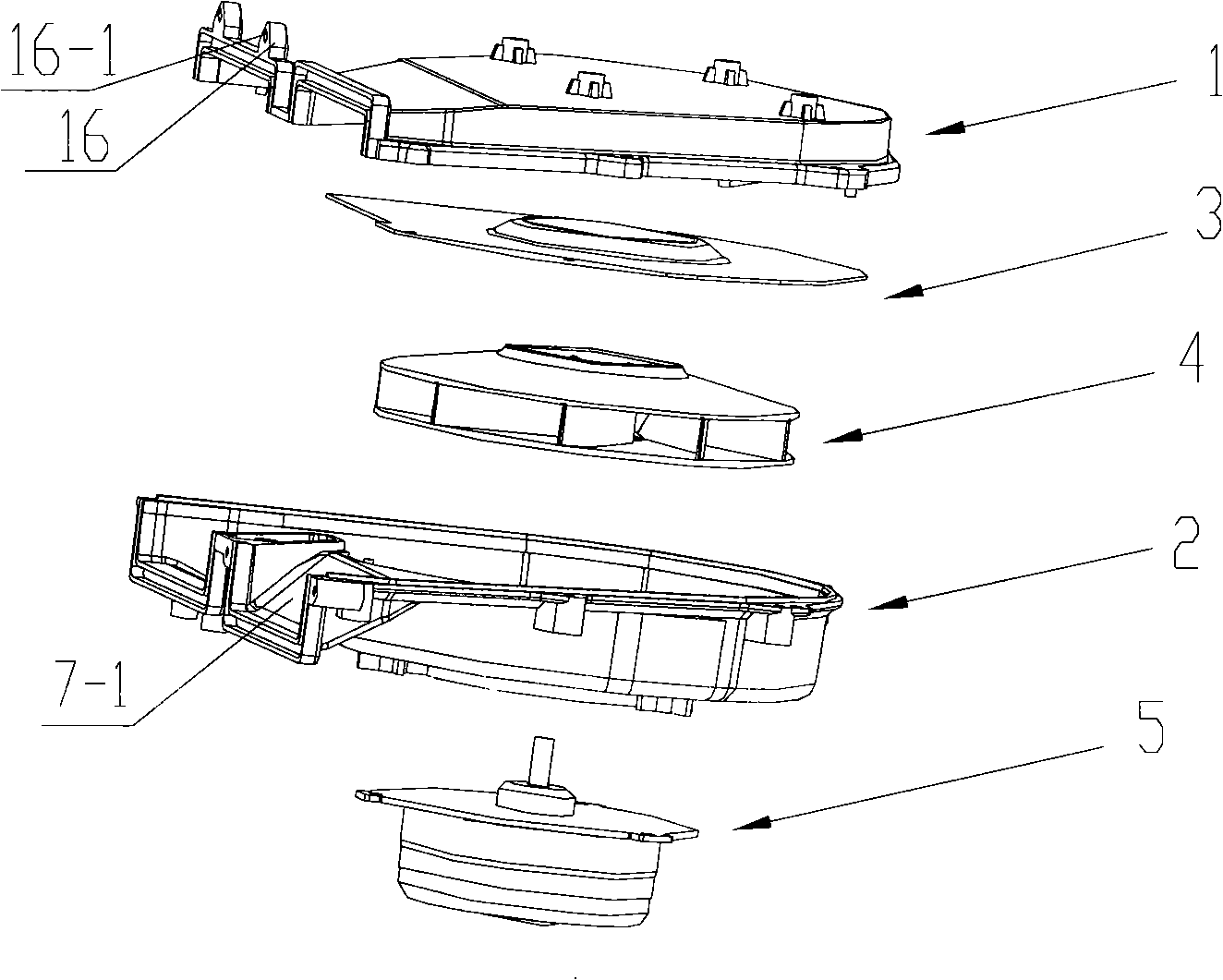

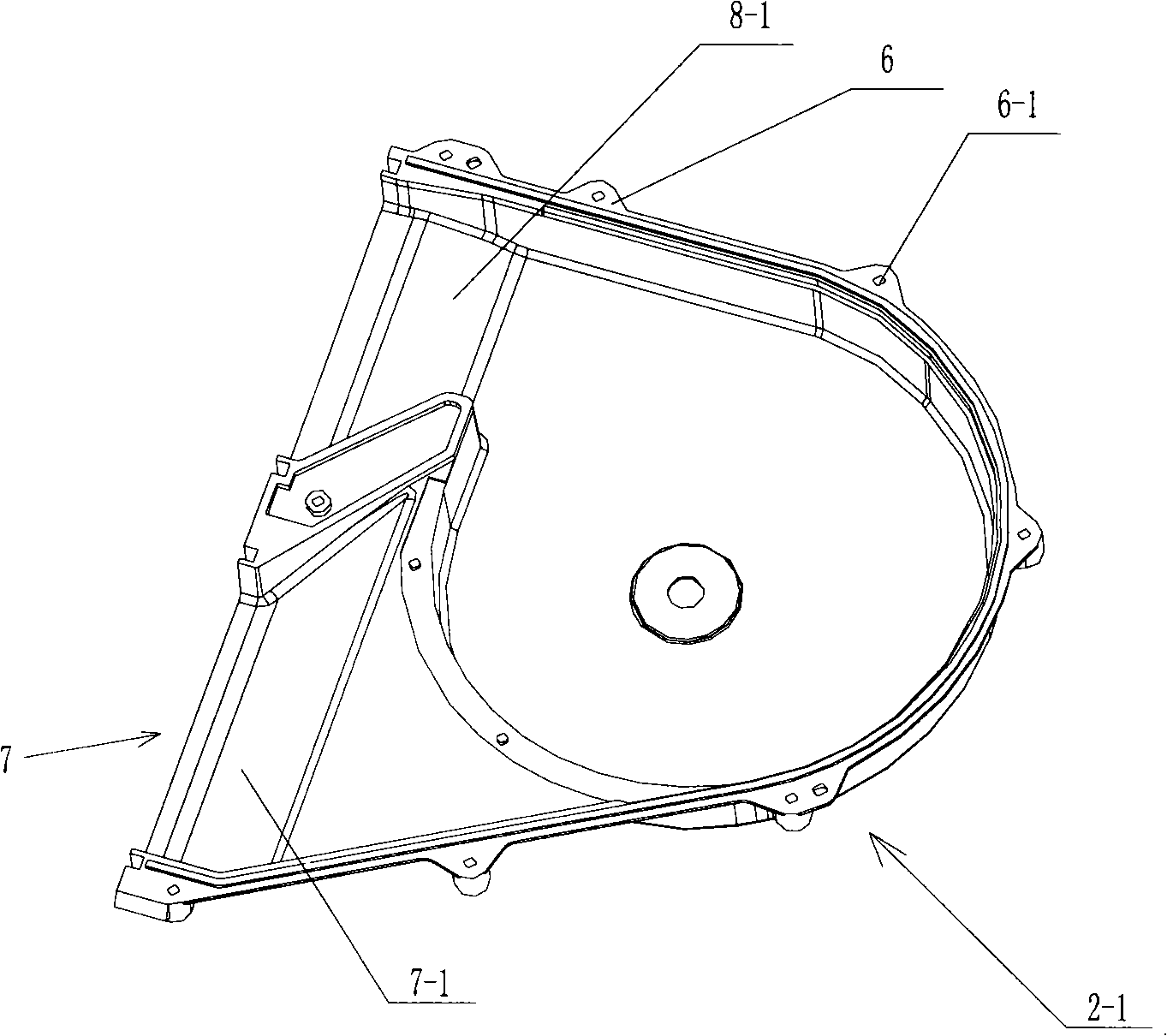

[0034] Embodiment one, such as Figure 2-6 As shown, the present invention proposes a fan, which includes an upper cover 1 and a volute 2, the upper cover 1 and the volute 2 have a part of the frame of the inlet 7 and the air outlet 8 adjacent to each other, the upper cover 1 and the volute A turning air channel is formed between the top surfaces 3 of the casing, and the inlet 7 of the turning air channel is adjacently arranged on one side of the air outlet 8, that is, after the upper cover 1 is fastened to the volute 2, an inlet on the same side of the volute is formed 7 and the air outlet 8, the frames of the inlet 7 and the air outlet 8 in this embodiment are square and located on the same plane, the actual positional relationship can be determined according to the needs. Installing lugs 16 are provided around the frame of the inlet 7 and the air outlet 8, and the mounting lugs 16 have screw holes 16-1 for connecting with other components. , There is a bolt hole 6-1 on the...

Embodiment 2

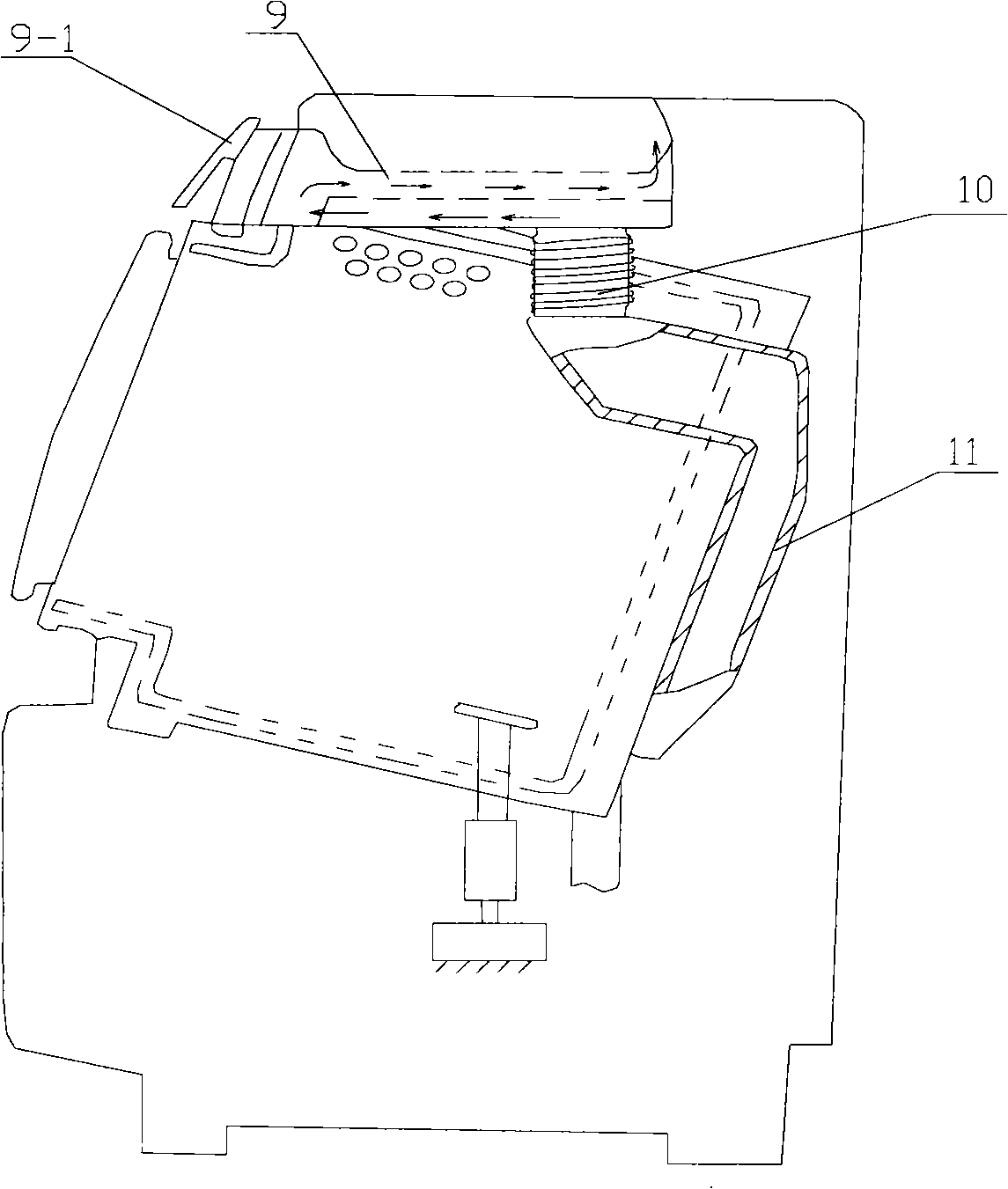

[0039]Embodiment two, such as Figure 7 and Figure 8 As shown, the present invention further proposes an all-in-one washing and drying machine with the fan described in Embodiment 1, including a condenser 11 and a lint filter, and the lint filter is located in the lint filter housing 9-2, so Figure 7 Not shown in the figure, the lint filter housing 9-2 is connected with the inlet 7 of the fan by bolts, the air outlet 8 of the fan is connected with the heat exchanger 12, and the airflow sucked from the inlet 13 is dehumidified by the condenser 11, and the airflow flows smoothly. as Figure 7 The arrow shown enters the lint filter. Since the lint filter housing 9-2 is a straight sleeve and is directly connected to the fan inlet 7, the airflow blown from the lint filter directly enters the inlet 7. The airflow blown in by the inlet 7 follows the upper slope 7-1 to the top of the volute top surface 3 and turns to the air duct, then enters the fan 4 from the air inlet 3-2 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com