Plasma non-oil ignition system for low volatile component coal

An oil-free ignition and low volatile technology, applied in the field of thermal boilers, can solve the problems of ignition failure, low volatile content, unsatisfactory application, etc., and achieve the effect of high work efficiency, reasonable and simple structure, and wide range of coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

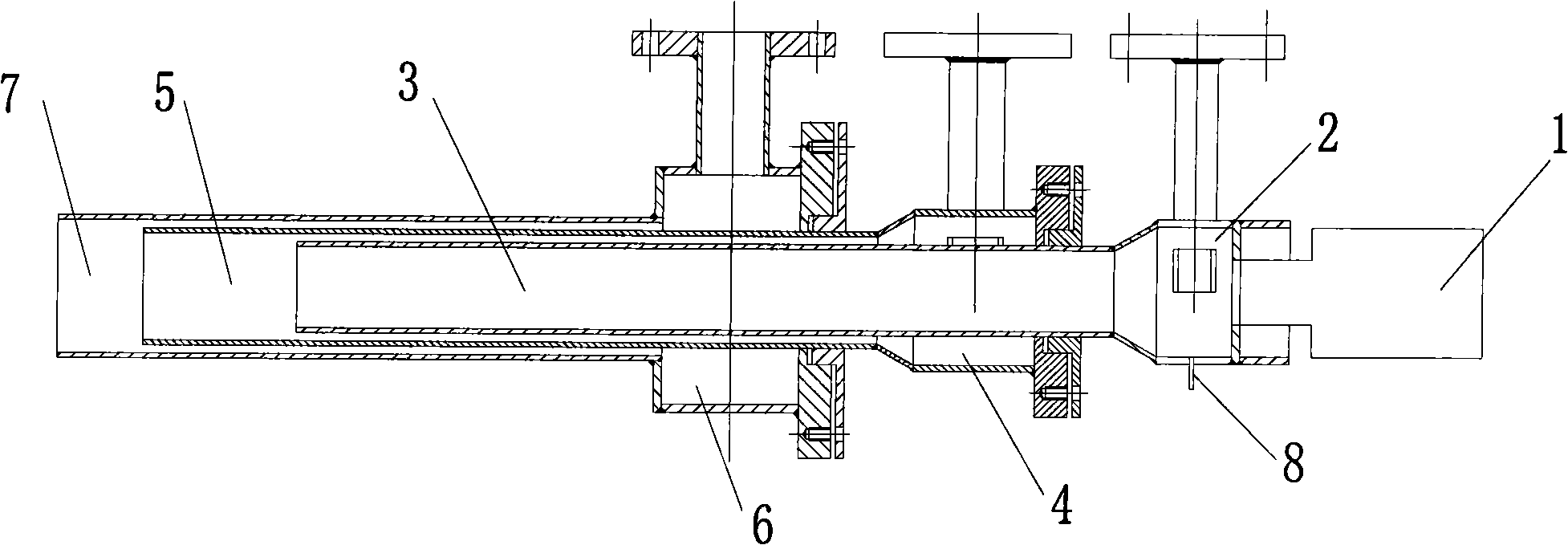

[0011] refer to figure 1 , is the plasma oil-free ignition system for low volatile coal of the present invention, including a plasma generator 1 and a burner. The innermost layer of the burner is the reaction chamber 2 and the reaction cylinder 3, the outermost layer is the air chamber 6 and the air cylinder 7, the middle layer is the air coal chamber 4 and the air coal cylinder 5, and the coaxial sleeve type is arranged between the three layers, each There are gaps between the layers for ventilation or pulverized coal air flow. The wind coal cylinder 5 connected to the outlet of the wind coal chamber 4, the air cylinder 7 connected to the outlet of the wind chamber 6; Outer end; the air chamber 6 and the air cylinder 7 are set on the outer periphery of the air coal cylinder 5, and the air cylinder 7 protrudes from the outer end of the air coal cylinder 5. A plasma generator 5 is coaxially installed opposite to the outlet of the reaction chamber 2 as an ignition source.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com