Dryer

A dryer and drying technology, which is applied in dryers, food drying, drying solid materials, etc., can solve the problems that dust is easy to adhere to the burner, and the burner is easy to turmoil, so as to achieve stable combustion, promote mixing, and promote transfer effect

Inactive Publication Date: 2010-09-08

ISEKI & CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in Patent Document 1, the dryer with the above-mentioned structure has a structure in which the dust mixed in and attached to the grain is discharged from the discharge port of the through passage toward the burner as the drying operation starts. Since the burner directly faces the exhaust air, There are disadvantages such as the combustion of the burner is prone to disorder

Moreover, there are also disadvantages such as dust is easy to adhere to the burner.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

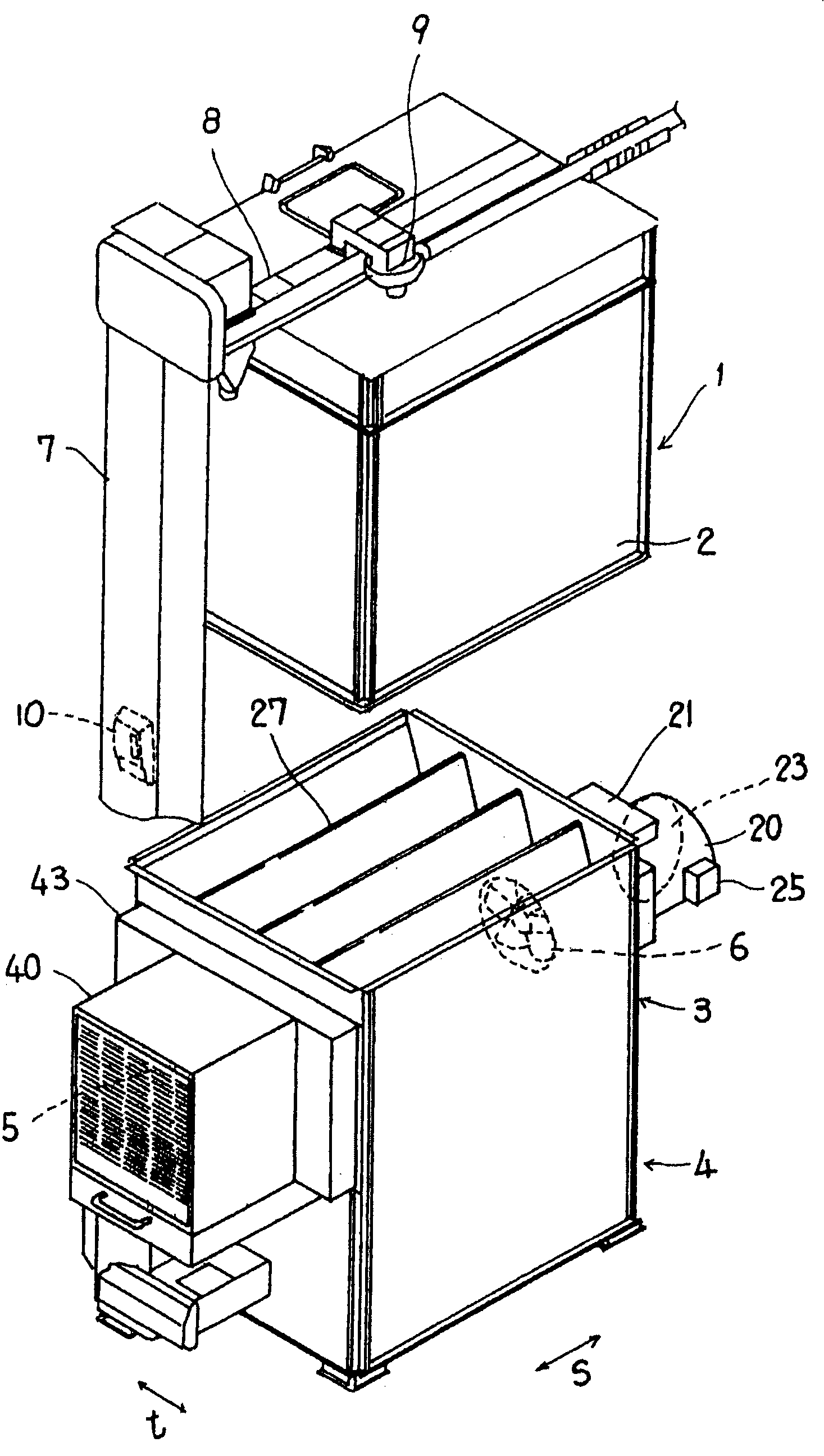

The invention relates to a drier in order to, in the drier with the function of returning air drafting and mixing with the hot blast flow, make the burning flame in the burner stable and promote the mixing of the hot blast and the air draft to achieve a highly effective drying. The drier in the invention is characterized in that: it is equipped with a burner (5) to generating hot blast; a hot blast chamber (11) for the hot blast to pass through; an exhausting fan (6) for absorbing and discharging the hot blast supplied to the dried object to absorb the moisture in the dried crop object as drafted air; and a returning channel for supplying the drafted air from fan exhausting fan (6) to the hot blast chamber (11). The exhaust port (e) of the returning channel is formed on a position closer to the front end side of the burning flame (Q) than the burning tray surface position.

Description

technical field The present invention relates to a drying machine for agricultural products such as grains and shiitake mushrooms, marine products, or wood. Background technique Patent Document 1 (Japanese Unexamined Patent Publication No. Sho-61-195266) describes a dryer that returns exhaust air to merge with hot air to dry. However, in Patent Document 1, the dryer with the above-mentioned structure has a structure in which the dust mixed in and attached to the grain is discharged from the discharge port of the through passage toward the burner as the drying operation starts. Since the burner directly faces the exhaust air, There is a disadvantage that the combustion of the burner is easily disturbed. Furthermore, there is a disadvantage that dust tends to adhere to the burner. Contents of the invention The object of the present invention is to solve this problem and to perform efficient drying by stabilizing the combustion flame of the burner and promoting mixing of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F26B3/02F26B21/00F26B23/02

CPCA23B9/025A23B9/08A23V2300/10

Inventor 西野荣治向山直树

Owner ISEKI & CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com