Deposition press combined solid-liquid separation column

A solid-liquid separation and composite technology, applied in the direction of settling tanks, feeding/discharging devices of settling tanks, presses, etc., can solve the problems of poor reliability of separation work, no squeezing function, complex components, etc., and achieve fast Separation and fast processing, high work efficiency, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the present invention will be further explained through the embodiments and the accompanying drawings:

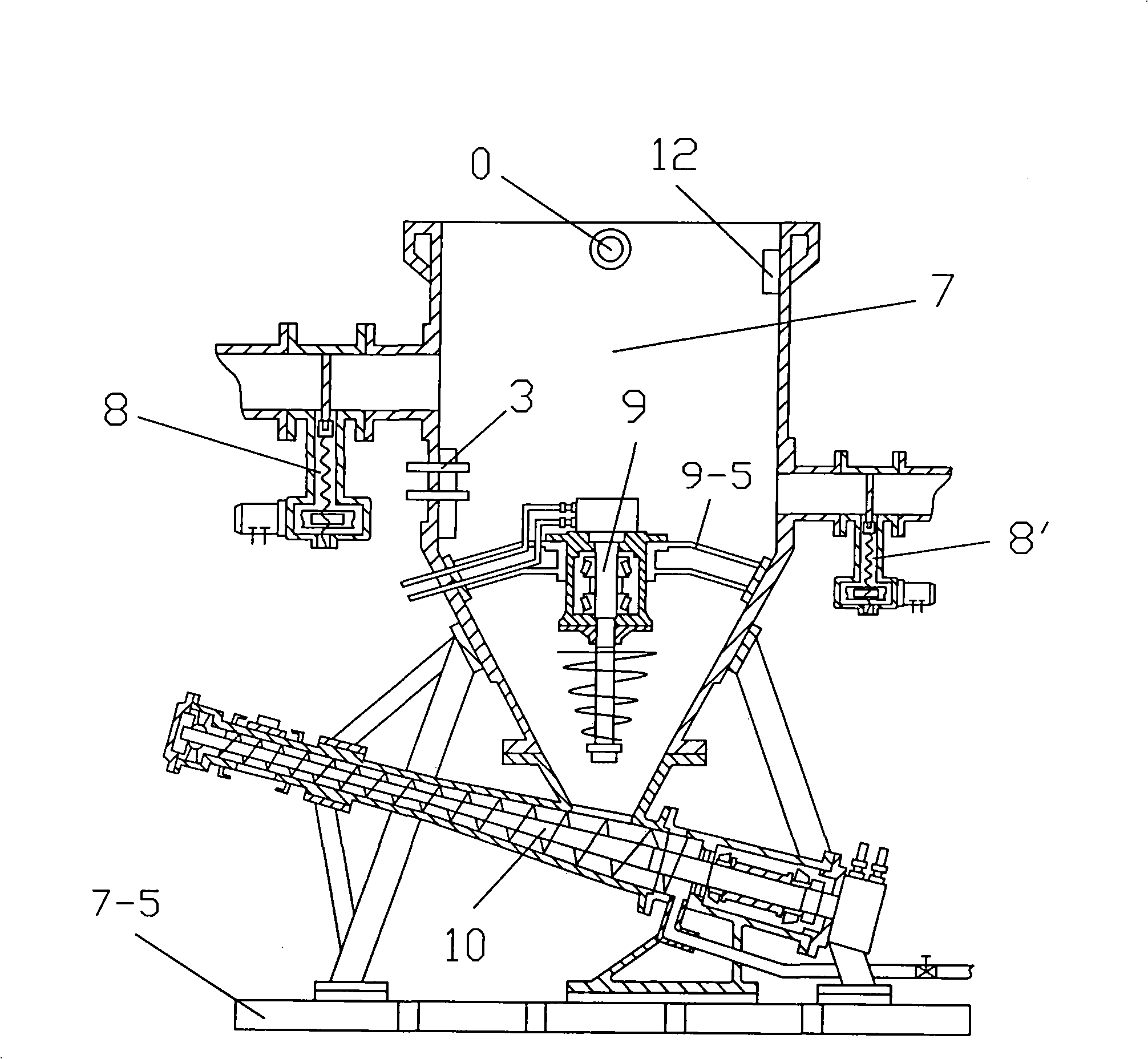

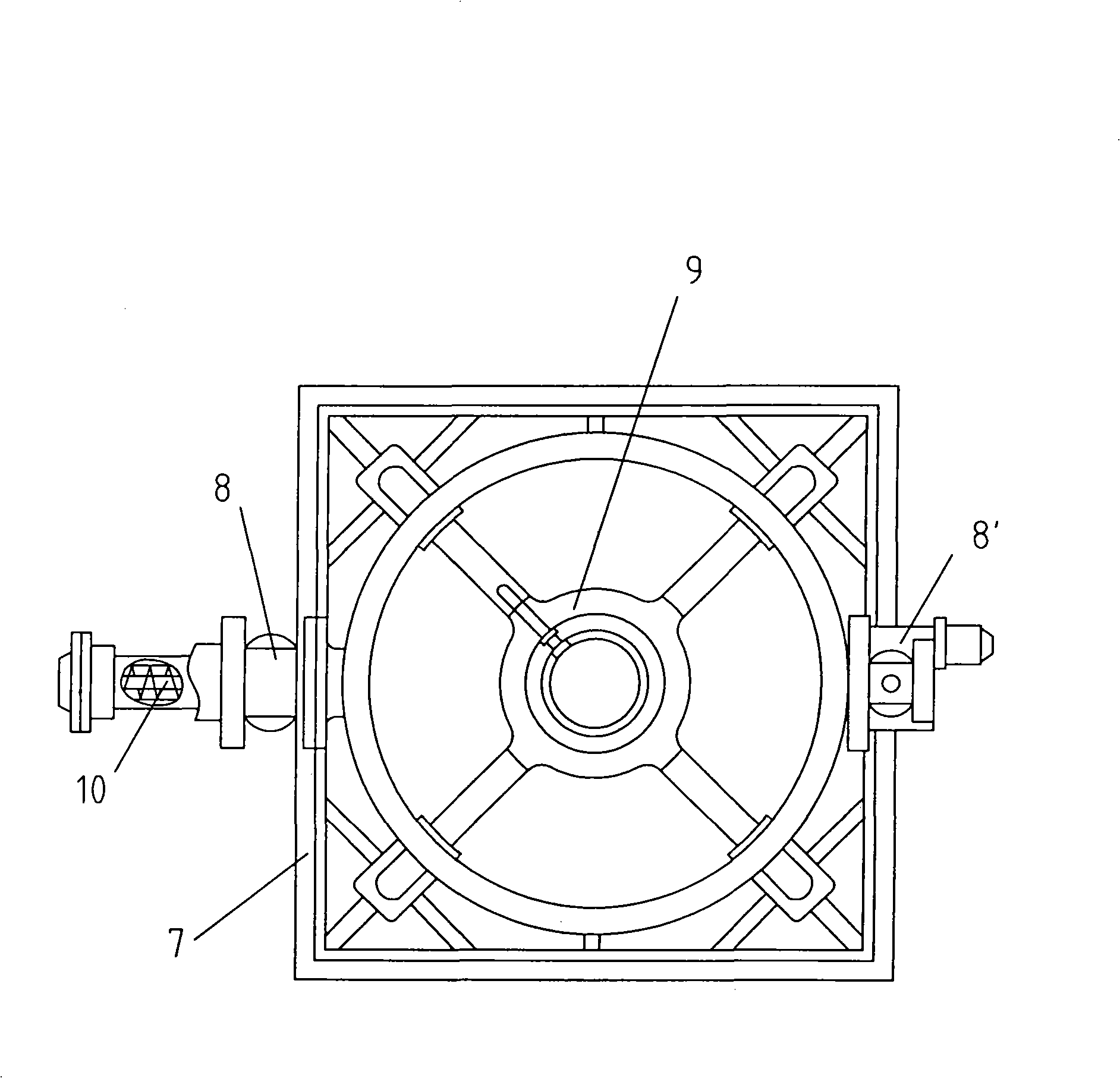

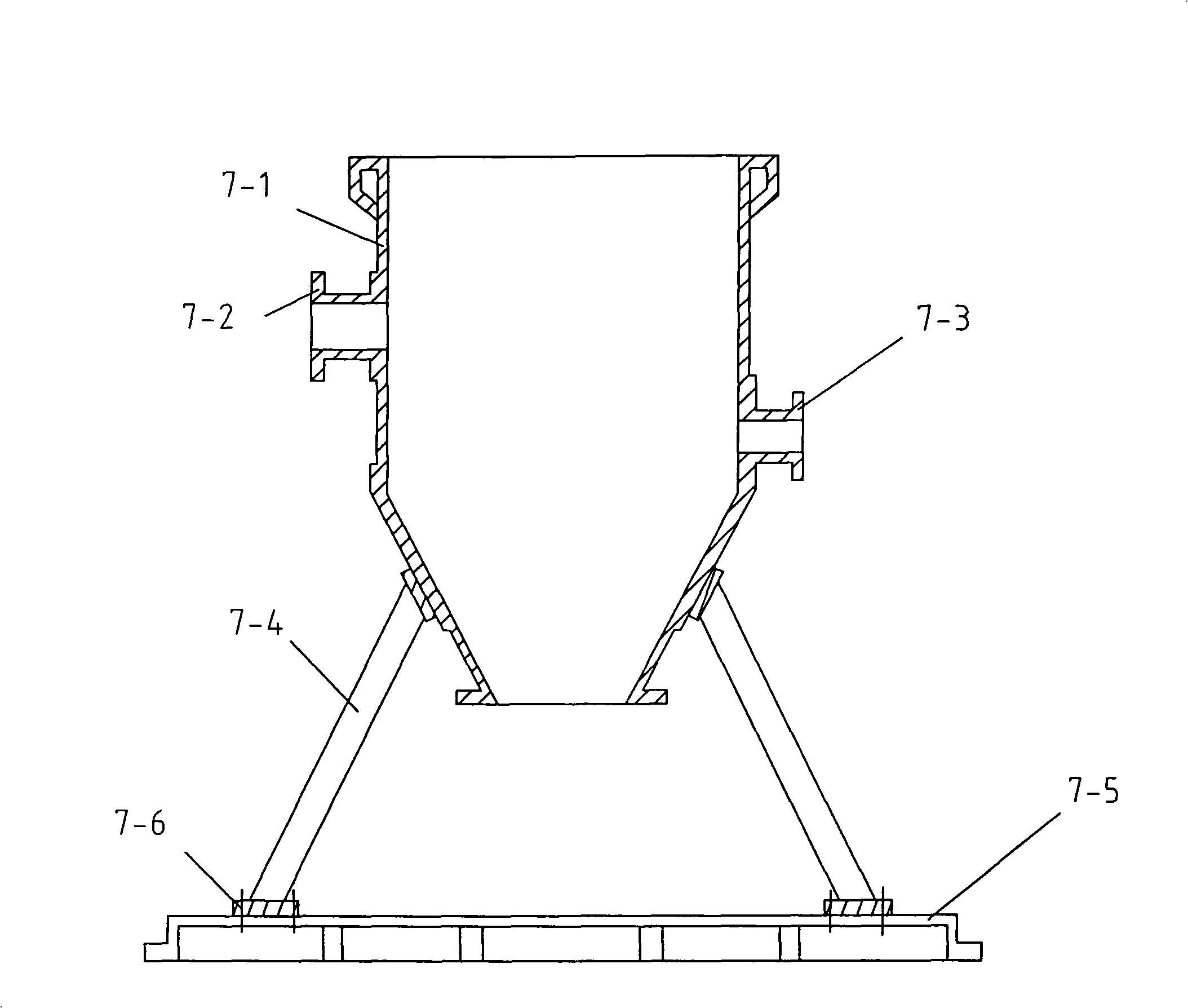

[0024] See figure 1 , figure 2 , The embodiment sinks and squeezes composite solid-liquid separation tower, including storage bin 7, mud feed valve 0, drain valve 8, suspension drain valve 8', vertical conveyor, drive bridge 9-5, squeezer , Base 7-5 and control system 11. The mud feed valve 0 is installed on the top of the storage bin 7, and the storage bin 7 is fixed on the base 7-5 through storage bin supports. The clear liquid valve 8 and the suspension drain valve 8'are installed on the wall of the storage bin 7 Above, the clear liquid discharge valve 8 is located above the suspension discharge valve 8', the vertical conveyor is located in the center of the storage bin 7, the discharge end of the vertical conveyor faces the bottom end of the storage bin 7, and the vertical conveyor is located in the storage bin 7. Inside, the drive bridge 9-5 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com