Method for preparing unsaturated polyester resin from wastes of benzoic anhydride production process and distillation fraction

A production process, polyester resin technology, applied in the field of polymer compound synthesis manufacturing, can solve the problems of high cost, waste of energy, complicated process, etc., and achieve good economic benefits, reduce pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

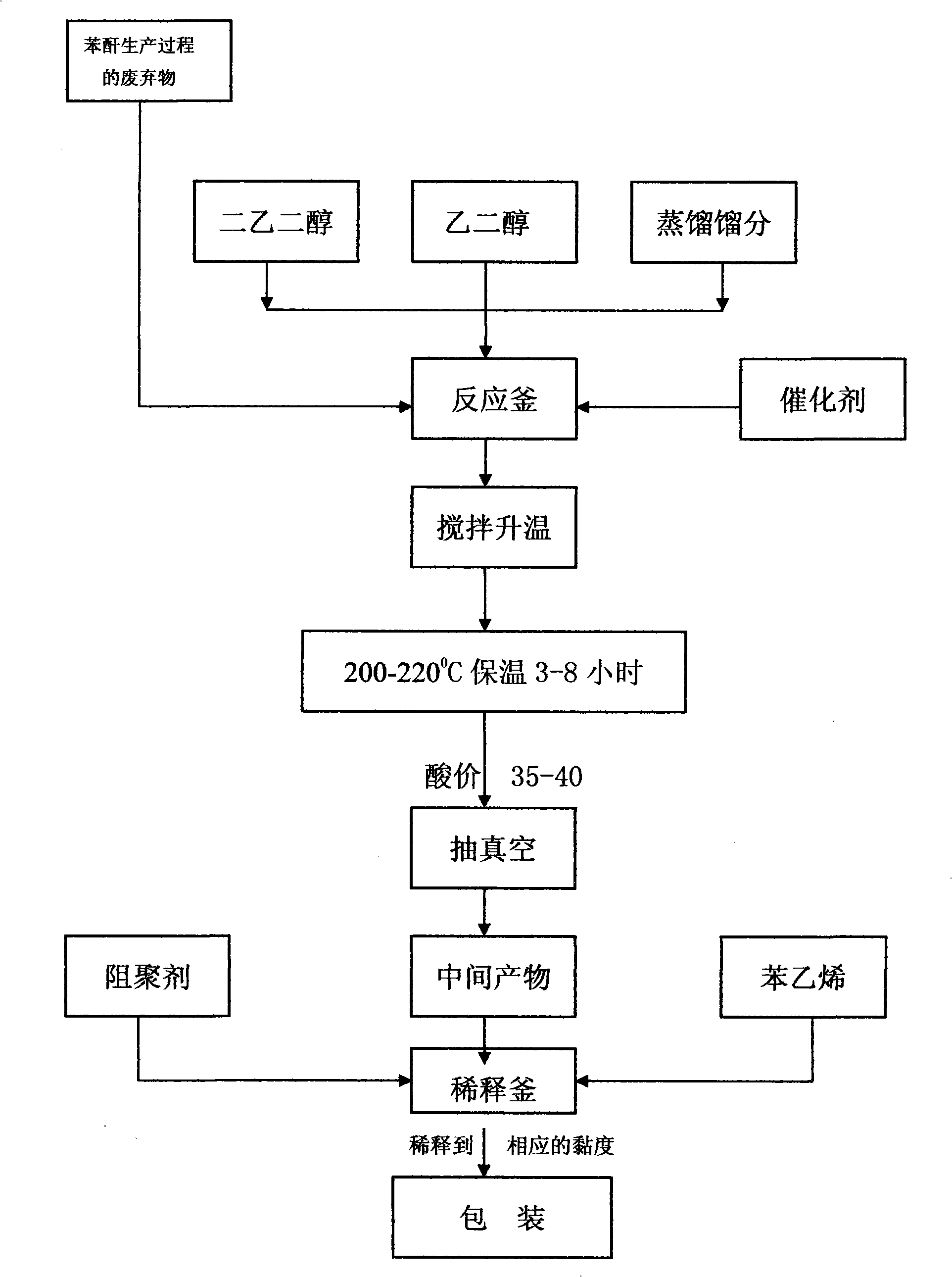

Method used

Image

Examples

Embodiment 1

[0045] Drop into 5 tons of sour water in the reactor, which contains 0.1 tons of phthalic acid, 0.85 tons of maleic acid, 0.1 tons of benzoic acid, 0.025 tons of methylbenzoic acid, and 3.575 tons of other substances (such as : water and other substances), negative pressure distilled water, until the water output reaches 75% of the theoretical water output, then drop into 1 ton of distillation cut (which contains 0.25 tons of benzoic acid and 0.75 tons of phthalic anhydride), 1 ton of diethylene glycol, 1 ton of ethylene glycol, 100ppm catalyst organotin, use a stirring device to evenly stir the materials in the reactor and gradually raise the temperature. When the temperature of the reactor rises to 200°C, the temperature is controlled at 200°C to 220°C for about 3 ~8 hours; when the acid value reaches the theoretical value of 35, vacuumize the reaction kettle for 1 ~ 2h, add 100ppm of hydroquinone polymerization inhibitor and 1 ton of styrene in the dilution kettle (the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com