Steel for internal magnetic shield and manufacturing method thereof

A manufacturing method and magnetic shielding technology, which are applied to the field of inner magnetic shielding steel and inner magnetic shielding steel for making internal components of picture tubes, can solve the problems of adverse effects on the magnetic properties of materials, high production cost, low hardness, etc., and achieve good Effect of surface blackening and magnetic properties, good shape stability, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The molten steel is smelted according to the following chemical composition: C: 0.001wt%, Si: 0.011wt%, Mn: 0.30wt%, P: 0.007wt%, S: 0.006wt%, Al: 0.006wt%, N: 0.0027wt%, and The amount is Fe and unavoidable impurities.

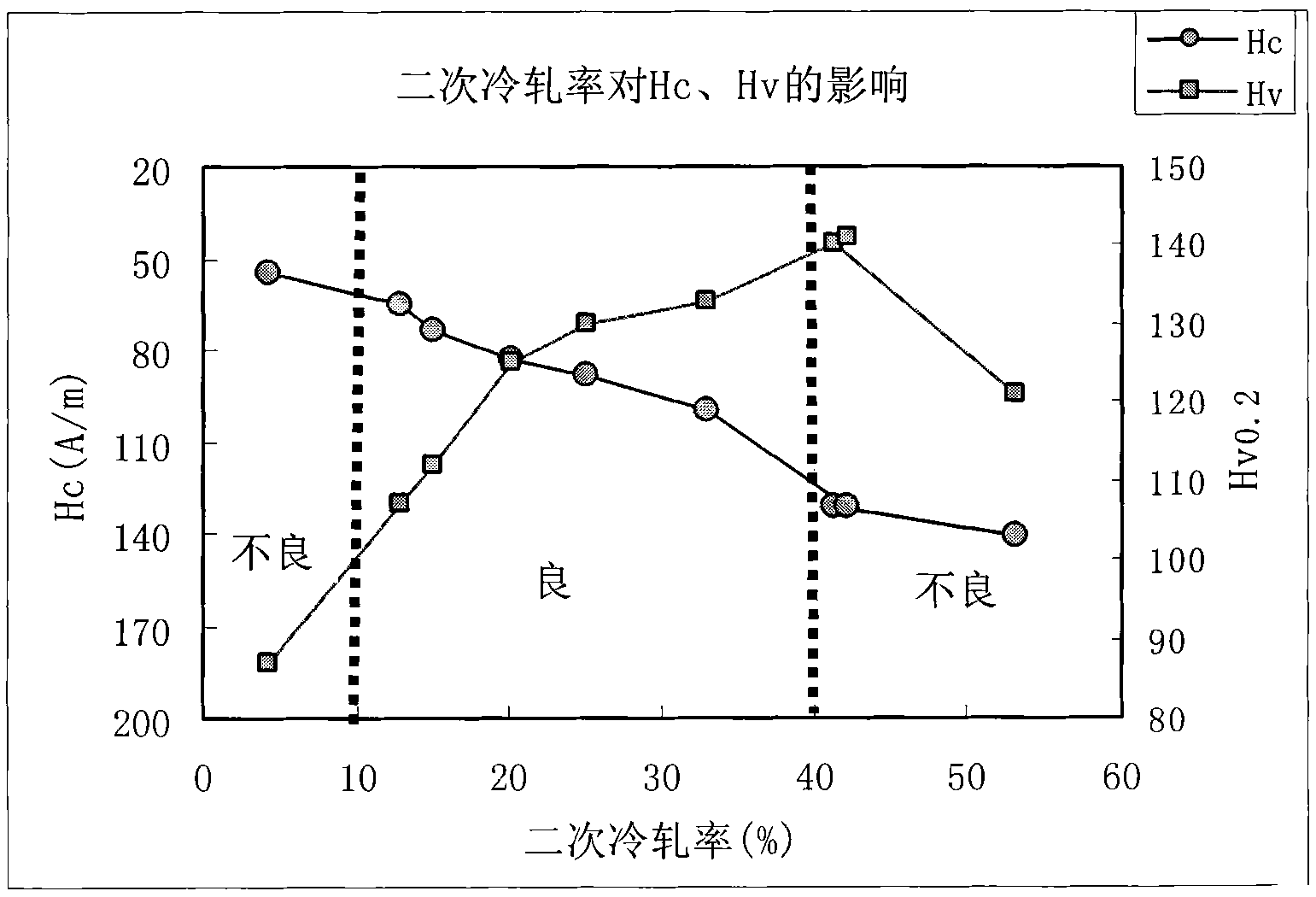

[0035] The molten steel smelted in the converter according to the above ratio is refined after the furnace, and then hot-rolled. The heating temperature of the hot rolling is 1150°C, the final rolling temperature is 880°C, and the coiling temperature is 680°C. After pickling, it is cold-rolled. The rolling deformation is 78%, and then annealed in a bell furnace at 620°C for 15 hours, and then undergoes secondary cold rolling with a secondary cold rolling deformation rate of 30%, and finally finished into finished coils.

Embodiment 2

[0037] The molten steel is smelted according to the following chemical composition: C: 0.002wt%, Si: 0.010wt%, Mn: 0.45wt%, P: 0.013wt%, S: 0.004wt%, Al: 0.003wt%, N: 0.0021wt%, and The amount is Fe and unavoidable impurities.

[0038] The embodiment is the same as in Example 1, wherein the hot rolling heating temperature is 1130°C, the finish rolling temperature is 930°C, the coiling temperature is 620°C, the first cold rolling deformation is 82%, the bell annealing temperature is 690°C, and the annealing time is 18 hours. The secondary cold rolling deformation rate is 15%.

Embodiment 3

[0040] The molten steel is smelted according to the following chemical composition: C: 0.004wt%, Si: 0.005wt%, Mn: 0.21wt%, P: 0.009wt%, S: 0.004wt%, Al: 0.008wt%, N: 0.0023wt%, and The amount is Fe and unavoidable impurities.

[0041] The implementation is the same as in Example 1, wherein the hot rolling heating temperature is 1200°C, the finishing rolling temperature is 890°C, the coiling temperature is 730°C, the first cold rolling deformation is 90%, the bell annealing temperature is 730°C, and the annealing time is 13 hours , The secondary cold rolling deformation rate is 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com