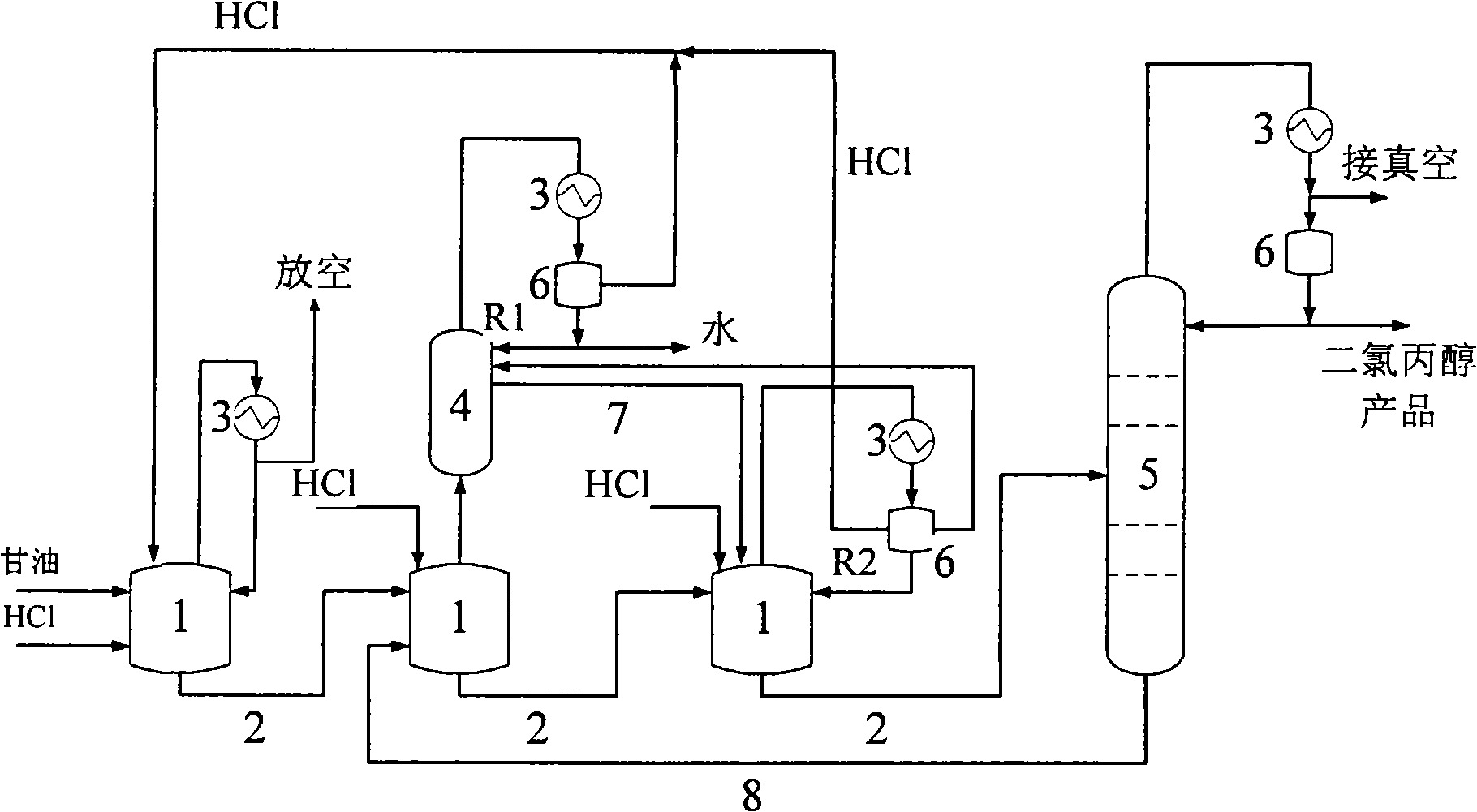

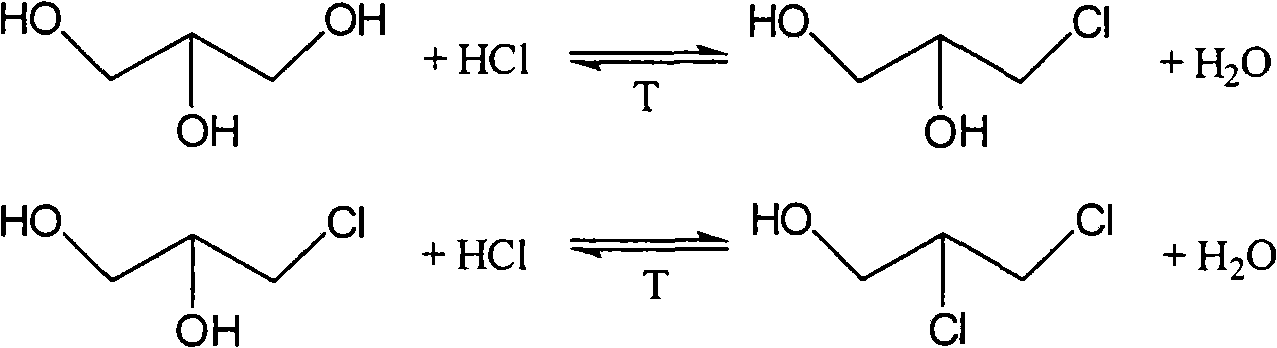

Technique and system for preparing dichloropropanol by autocatalysis reaction of glycerine and hydrogen chloride

A technology of dichloropropanol and hydrogen chloride, applied in the chemical industry, can solve the problems of increasing production cost, environmental pollution, increased catalyst consumption, large catalyst consumption, etc., to eliminate the formation of high boiling point by-products, and reduce production costs , Improve the effect of reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 0.5 mol glycerin (containing 99.5% glycerol) to the reaction device with a rectification column on the top of the bubbler reactor, react at normal pressure and 160°C, and continuously feed hydrogen chloride gas at a rate of 3L / h , continued for 8h, the reflux ratio was 3:1, the conversion rate of glycerol was 100% at the end of the experiment, the selectivity of monochloropropanediol was 46.4%, the selectivity of dichloropropanol was 53.2%, and the selectivity of heavy fraction diglycerol 0.4%.

Embodiment 2

[0039] In a magnetic stirred tank reactor, add 0.5mol glycerol (containing 99.5% glycerol), react under normal pressure and 105°C, and continuously feed hydrogen chloride gas at a rate of 0.6L / h for 50h. At the end of the experiment, glycerol The conversion rate is 89.8%, the selectivity of monochloropropanediol is 74.5%, the selectivity of dichloropropanol is 25.3%, and the selectivity of heavy fraction diglycerol is 0.2%.

Embodiment 3

[0041] Add 0.5 mol glycerin (containing 99.5% glycerol) to the reaction device with a rectification column on the top of the bubbler reactor, react at normal pressure and 140°C, and continuously feed hydrogen chloride gas at a rate of 3L / h , continued for 8h, the reflux ratio was 3:1, the conversion rate of glycerol was 100% at the end of the experiment, the selectivity of monochloropropanediol was 55.6%, the selectivity of dichloropropanol was 44.3%, the selection of heavy fraction diglycerol Sex is 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com