Smooth web and braiding method thereof

A snare and smooth technology, applied in braids, fabrics, textiles, etc., can solve the problems of thick snares, lower production efficiency, loose surface texture, etc., and achieve the effect of comfortable clothing design, convenient processing, and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

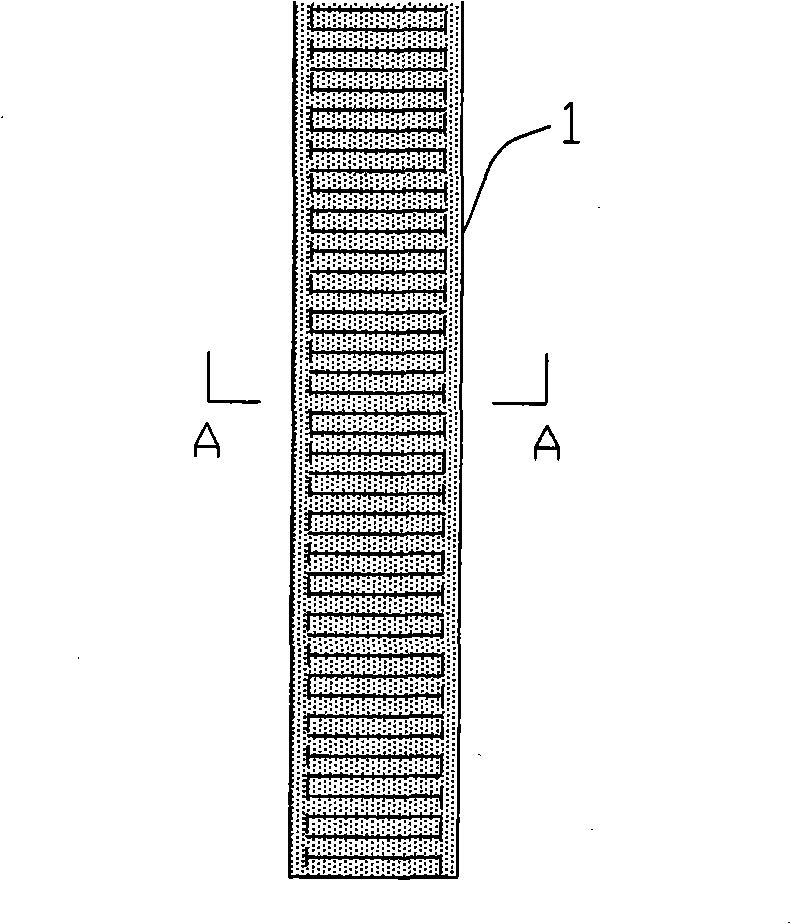

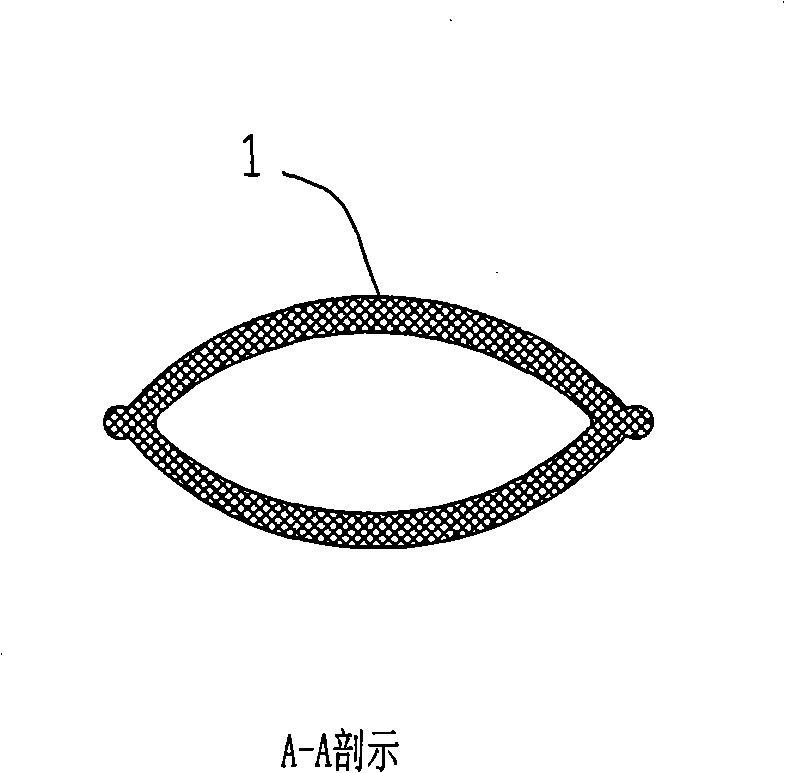

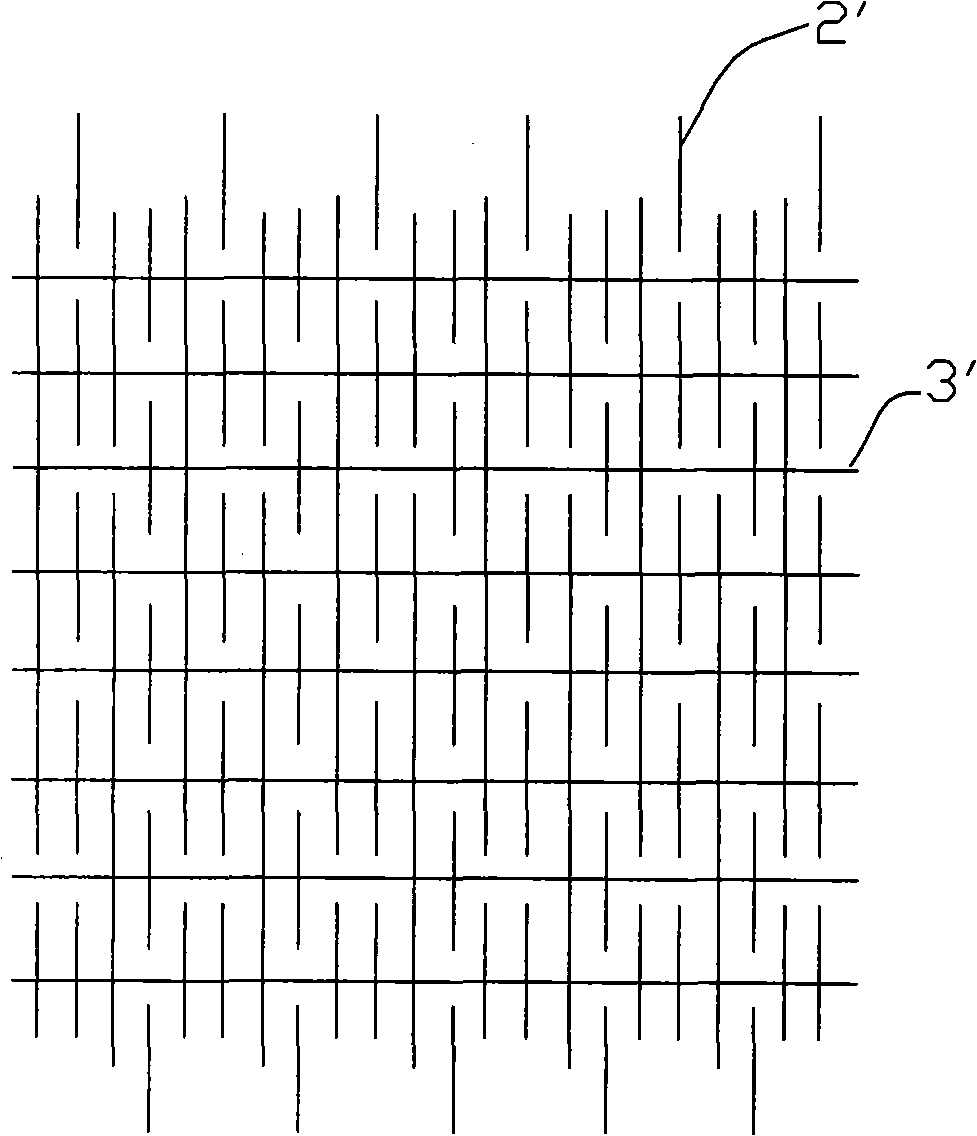

[0015] refer to figure 1 , figure 2 , Figure 4 , a smooth snare, including a hollow casing 1 made of upper and lower textile fabrics, the two sides of the casing are braided edges, and the casing 1 is composed of several warp threads 2 and contains at least one thermal fuse The weft threads 3 of 31 are uniformly interlaced and woven, and the inner and outer surfaces of the cover are fine and smooth surfaces with consistent lines. refer to image 3 , Figure 4 shown in the figure and Each represents an interweaving point of warp and weft, Indicates that the meridian 2' floats on the latitude 3', Represent warp thread 2 ' sinking under weft thread 3 ', compare known from the appearance structure structure of existing fabric and fabric of the present invention, existing fabric contains There are many intersection points, that is, a large number of warp threads 2' continuously float on the top of the weft thread 3', thus forming a loose and fuzzy surface structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com