Build process of building wall face sheet and building wall

A technology for building walls and construction methods, which is applied in the direction of building structures, buildings, building components, etc., can solve problems such as rigid facades and planes, uneven wall surfaces, and poor structural integrity, and achieve short construction periods and high wall quality. The effect of smoothing the body surface and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

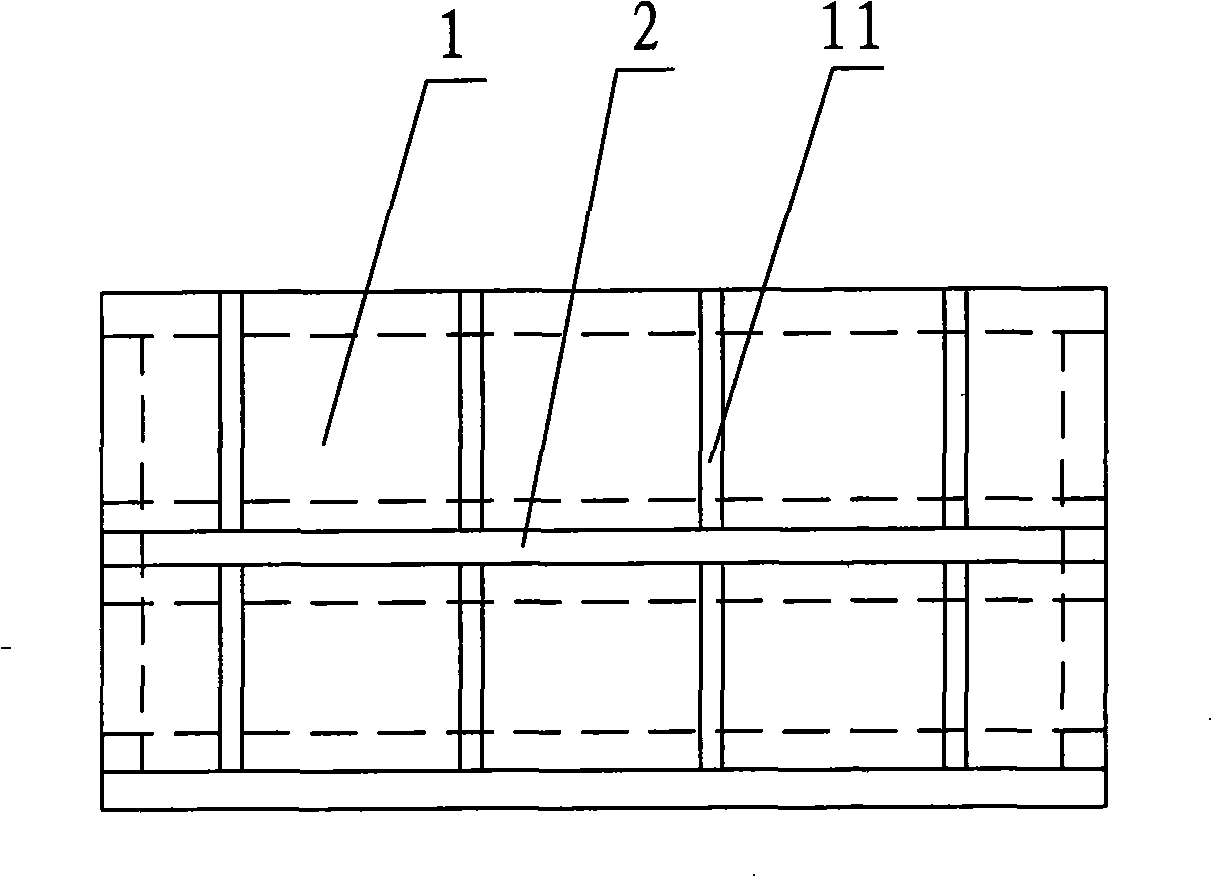

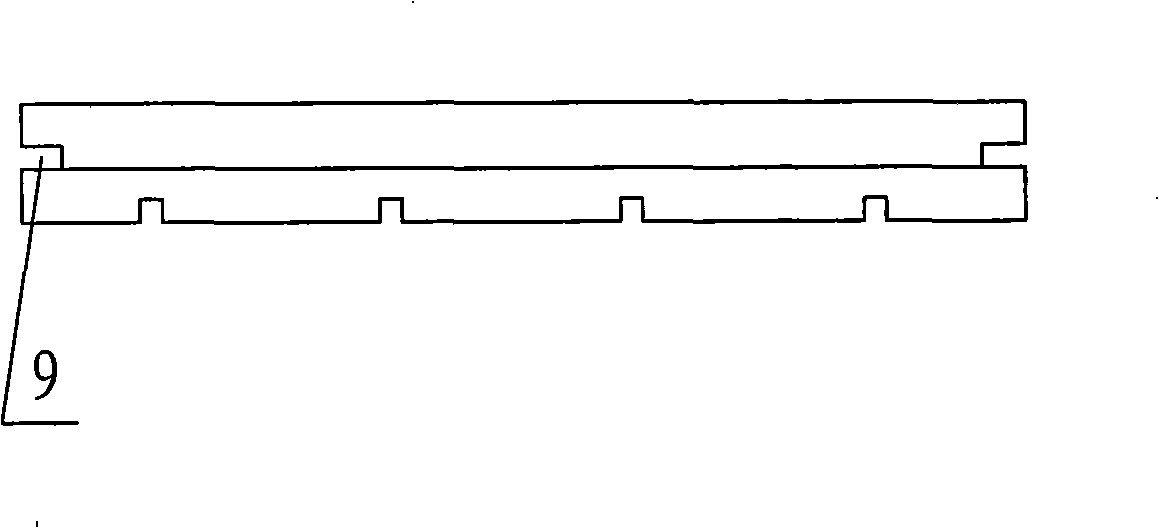

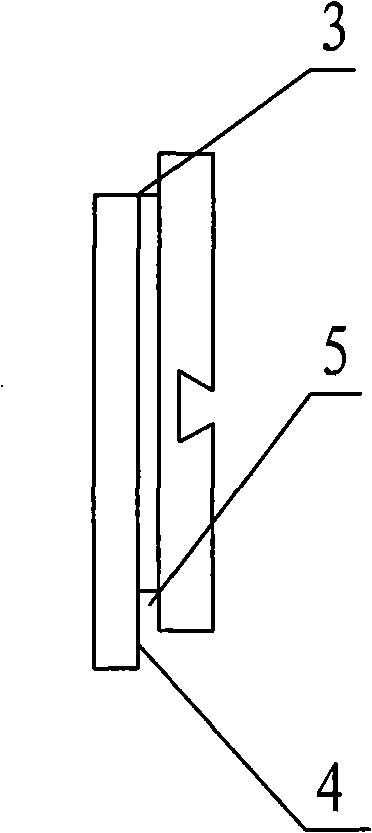

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention includes a strip-shaped plate body 1, wherein one plate surface of the plate body 1 has a dovetail groove 2 along its length direction and four grooves 11 along its width direction, and the two sides of the plate body 1 Two sides along its width direction have grooves 9 running through the width direction respectively, and two sides along its length direction of the plate body 1 have respectively matched step mating surfaces 3, 4, which are matched in the step The inner side of face 4 has a groove 5, has Shaped connecting piece 6 cooperates with it. When in use, the grooved board surfaces of the wall panels are arranged oppositely, and the two adjacent wall panels on the same side are lapped together by steps, and are fixed by the head of the connector 6, while the connector 6 Pull the wall panels on both sides to keep it stable; between the two adjacent wa...

Embodiment 2

[0030] Such as figure 1 , figure 2 , image 3 , Image 6 , Figure 7 , Figure 8As shown, the present invention includes a strip-shaped plate body 1, wherein one of the plate surfaces of the plate body 1 has a dovetail groove 2 along its length direction and four grooves 11 along its width direction. The two sides along its length direction are respectively provided with matching stepped mating surfaces 3 and 4, and the two sides of the plate body 1 along its width direction are respectively provided with grooves 9 penetrating the width direction, and the dovetail A connecting block 7 matching it is arranged in the groove 2, and the connecting block is connected with the connecting piece 8. During use, the board faces with grooves of the wall panels are arranged oppositely, two wall panels adjacent up and down on the same side are lapped together by steps, and the grooves of the two adjacent wall panels on the same side are 9 A waterproof strip 10 is provided inside, an...

Embodiment 3

[0032] Such as figure 1 , figure 2 , Figure 9 As shown, the present invention includes a strip-shaped plate body 1, wherein one plate surface of the plate body 1 has a dovetail groove 2 along its length direction and four grooves 11 along its width direction, and the other plate body 1 One board surface is an inclined plane, and the two sides of the board body 1 along its width direction are provided with grooves 9 running through the width direction respectively, and the two sides of the board body 1 along its length direction are provided with corresponding grooves 9 respectively. The step mating surfaces 3 and 4 of the step have a groove 5 on the inner side of the step mating surface 4. Shaped connecting piece 6 cooperates with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com