Mixed traction power supply equipment and control method

A traction power supply and control method technology, applied in the direction of output power conversion devices, electrical components, power lines, etc., can solve the problems of large output voltage fluctuations, cost increases, large fluctuations in DC voltage, etc., to achieve the suppression of DC voltage rise, The effect of preventing DC voltage drop, reducing harmonics and reactive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

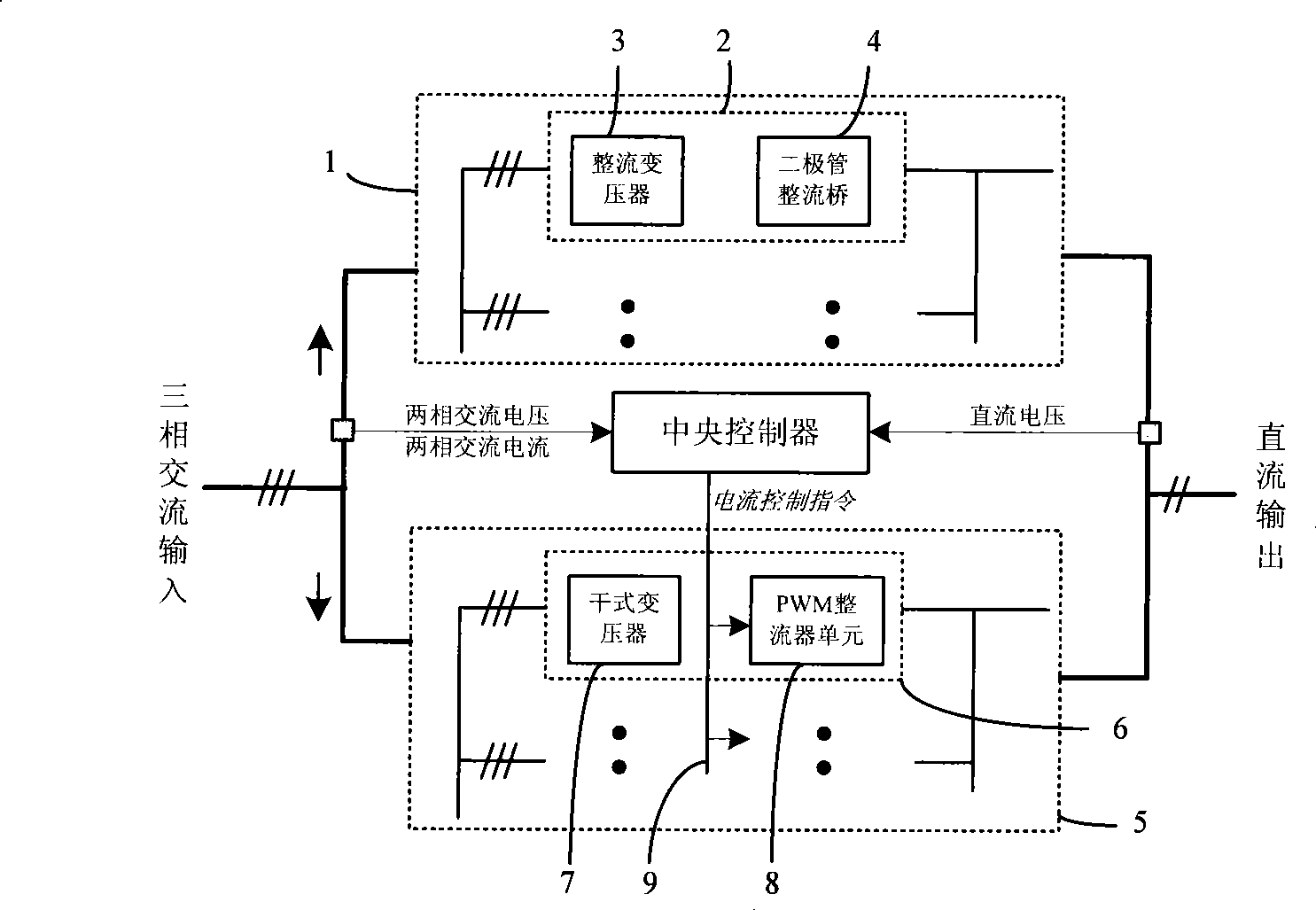

[0028] figure 1 In this embodiment, the rated DC output voltage is 750V, and the entire power supply device is composed of a 24-pulse diode rectifier unit, a PWM rectifier unit and a central controller.

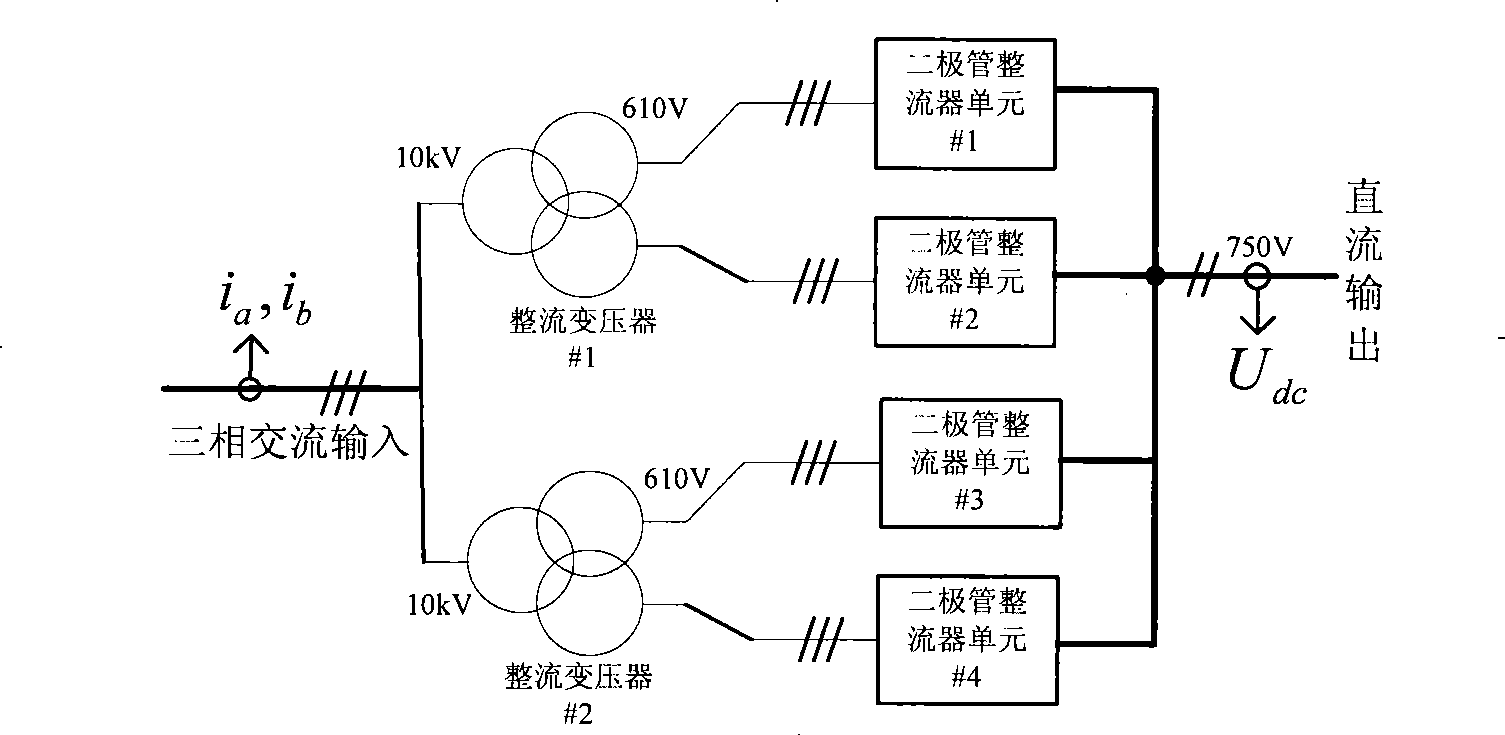

[0029] figure 2 It is a circuit diagram of a 24-pulse diode rectifier unit in this embodiment, which includes 2 phase-shifting rectifier transformers with three windings and 4 diode rectifier bridges. The rectifier transformer adopts epoxy resin casting dry-type transformer, the input voltage of the primary side of the transformer is 10kV, and the output voltage of the secondary side is 610V. The transformer connection mode adopts Dy11d0. In order to realize the 24-pulse rectification output, the primary sides of the two transformers need to adopt the extension triangle connection method.

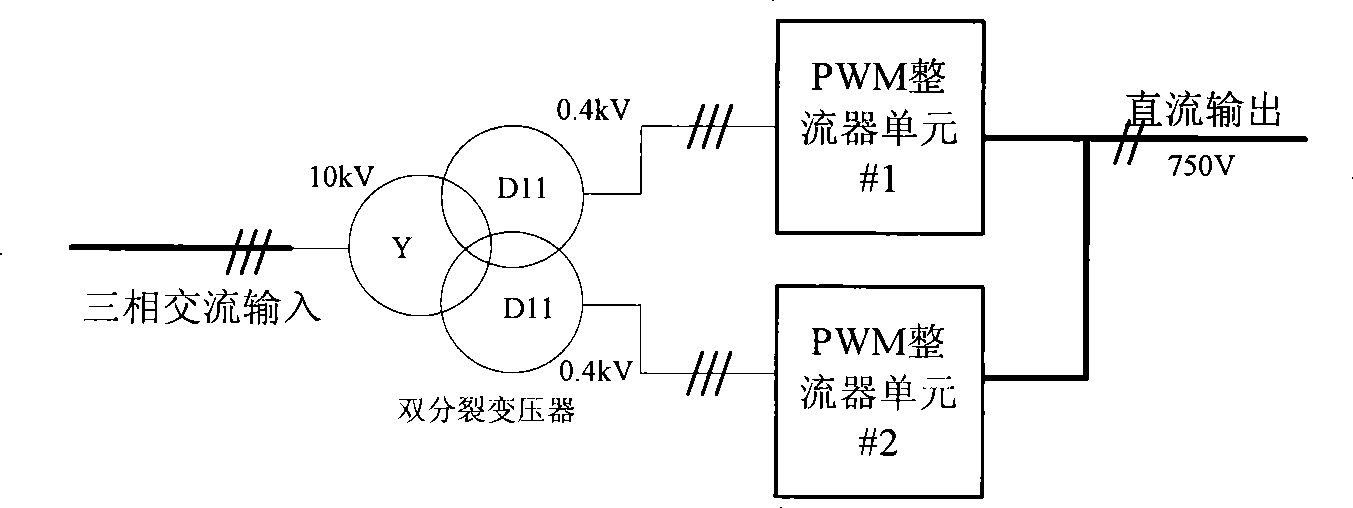

[0030] image 3 is the circuit diagram of the PWM rectifier unit in this embodiment. The PWM rectifier unit only includes a three-winding dry-type transformer and two PWM rectifier un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com