Method for detecting shortage of products packaged by aluminum foil by microwave and detector thereof

A microwave detection and detector technology, applied in the direction of using microwave flaw detection, can solve the problems of large size, high price, damage, etc., and achieve the effect of easy installation, simple detection method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

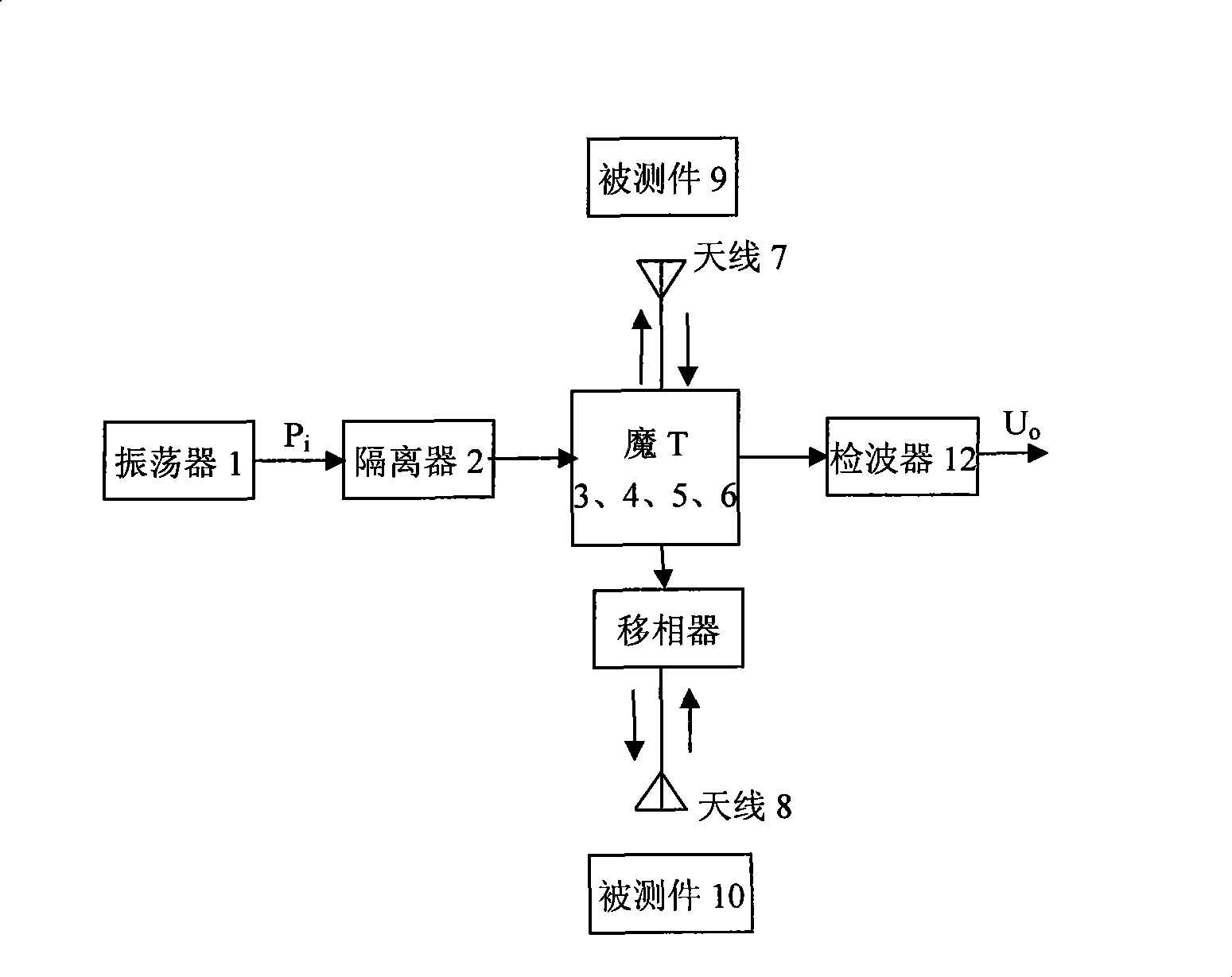

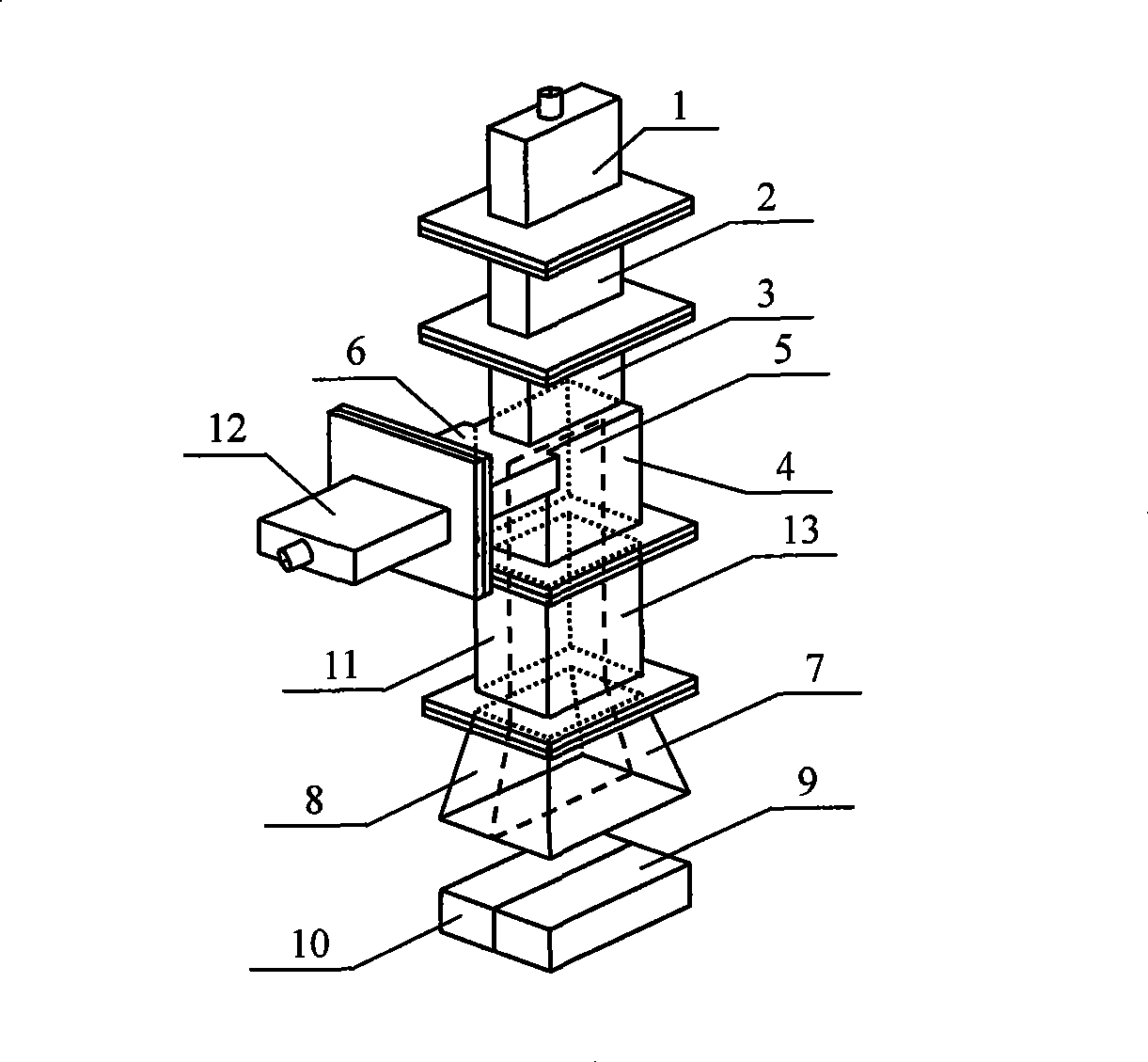

[0017] combine figure 1 , the microwave detection method for missing parts in aluminum foil packaging of the present invention utilizes the reflection and transmission characteristics of microwave signals of specific frequencies to different objects, and judges the phenomenon of missing parts in the whole box and package by detecting the amplitude and phase characteristics of the echo signal. Electrical signal output, the steps are: firstly provide a bias voltage to the microwave oscillator to make it work to generate a microwave signal of a specific frequency, the specific frequency value is determined according to the packaging material of the test piece, such as: 8μm thick aluminum foil packaging paper, choose 5GHz A microwave signal is enough, and for a 1μm thick aluminum foil wrapping paper, a 10GHz microwave signal should be selected.

[0018] Secondly, the microwave signal is input to the E-arm of the magic T, the signal is output by the two main arms of the magic T, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com