Nonvolatile memory and forming method for the same

A non-volatile memory technology, applied in the manufacture of electrical solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of low charge storage capacity, high charge loss capacity, poor charge capture ability, etc., to reduce Thermal budget, best programmatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are specifically cited below and described in detail with accompanying drawings.

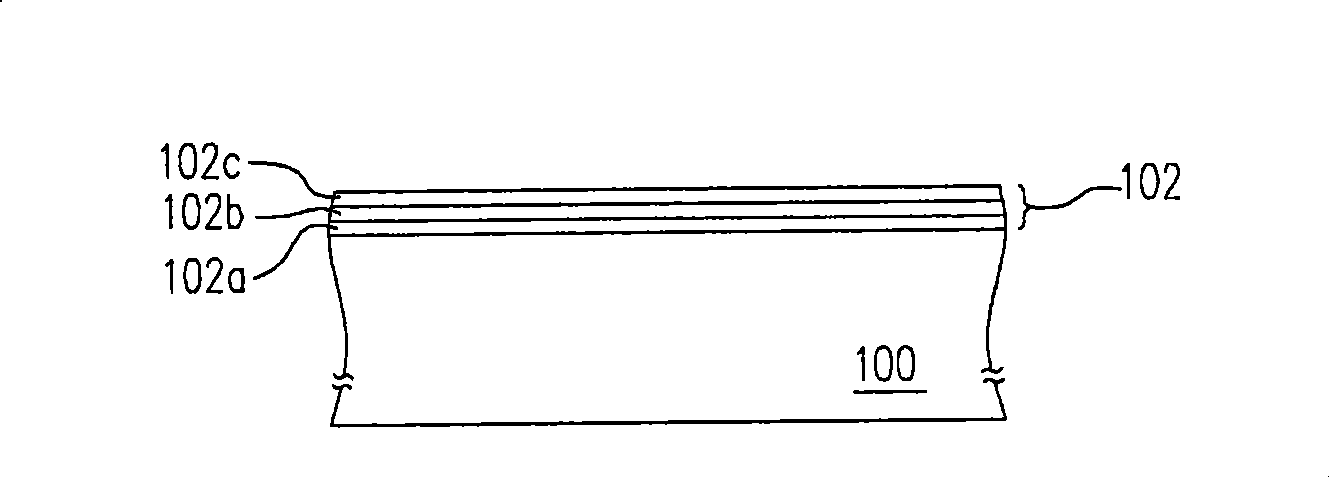

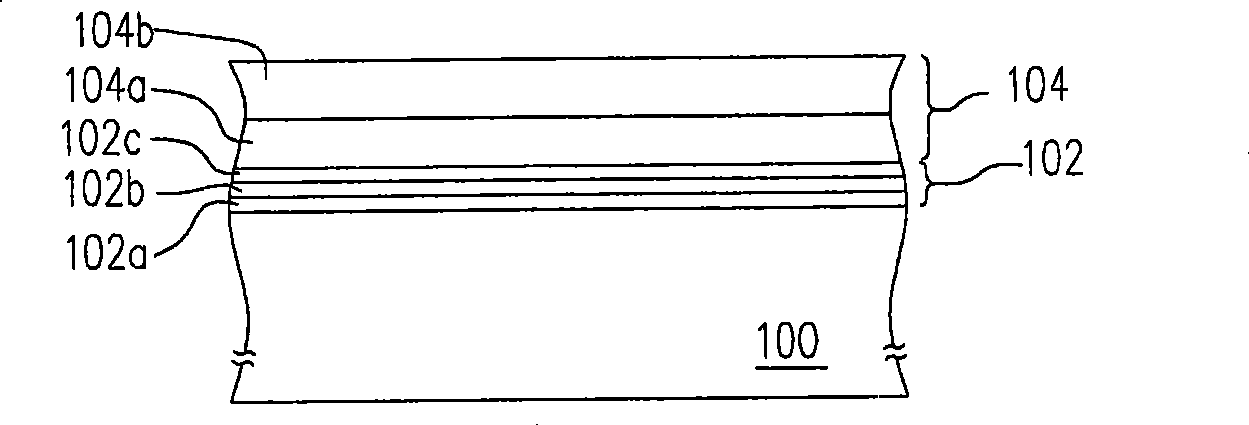

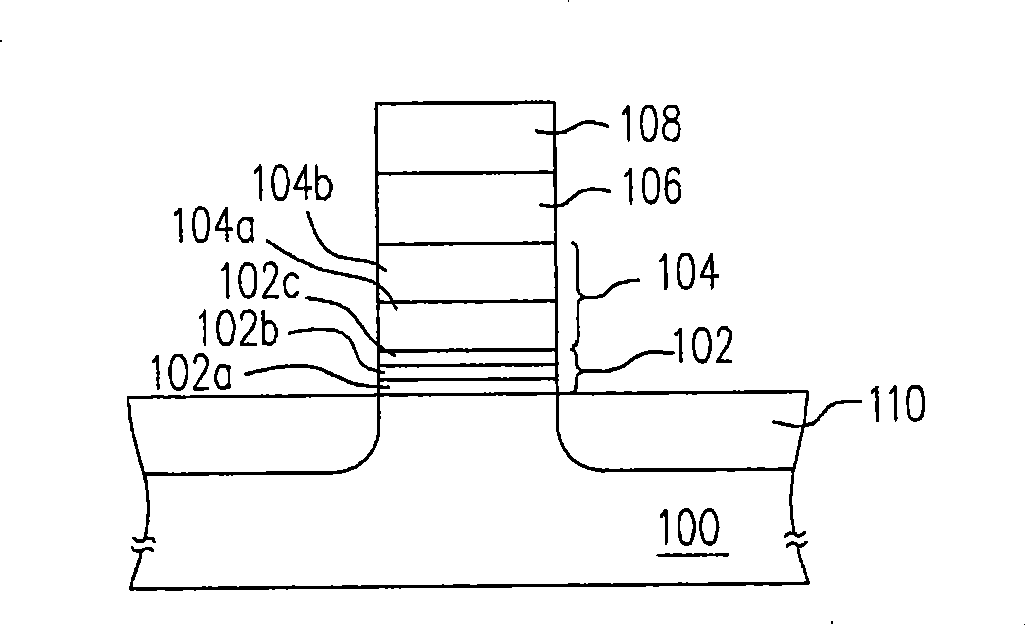

[0041] Figure 1A to Figure 1C Illustrated is a method for forming a non-volatile memory according to a preferred embodiment of the present invention. First please refer to Figure 1A , providing a substrate 100 , and then forming a tunneling layer 102 on the substrate 100 . The tunneling layer 102 can be a dielectric layer with a single-layer structure, and the material of the dielectric layer is, for example, silicon oxide or other dielectric materials with high dielectric constant. The methods for forming the single-structure dielectric layer include chemical vapor deposition, rapid high-temperature process, and ion oxidation process. In this embodiment, the tunneling layer 102, such as Figure 1AAs shown, it has a multi-layer structure, and its f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com