LED device

A technology of light-emitting diodes and substrates, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large differences in refractive index and reduced light extraction efficiency, so as to reduce the difference in refractive index, reduce the difference in refractive index, and increase total reflection. The effect of angle and light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

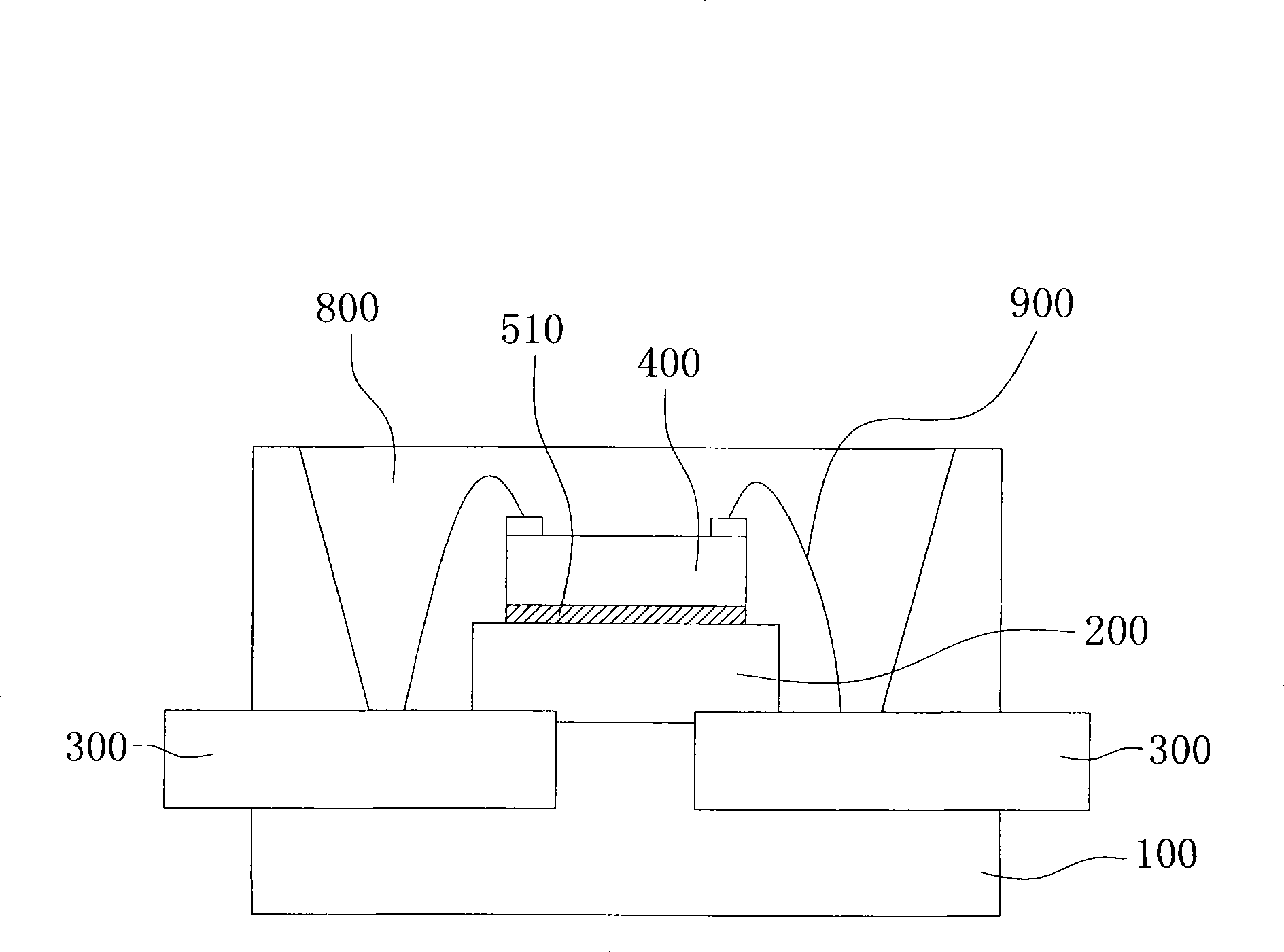

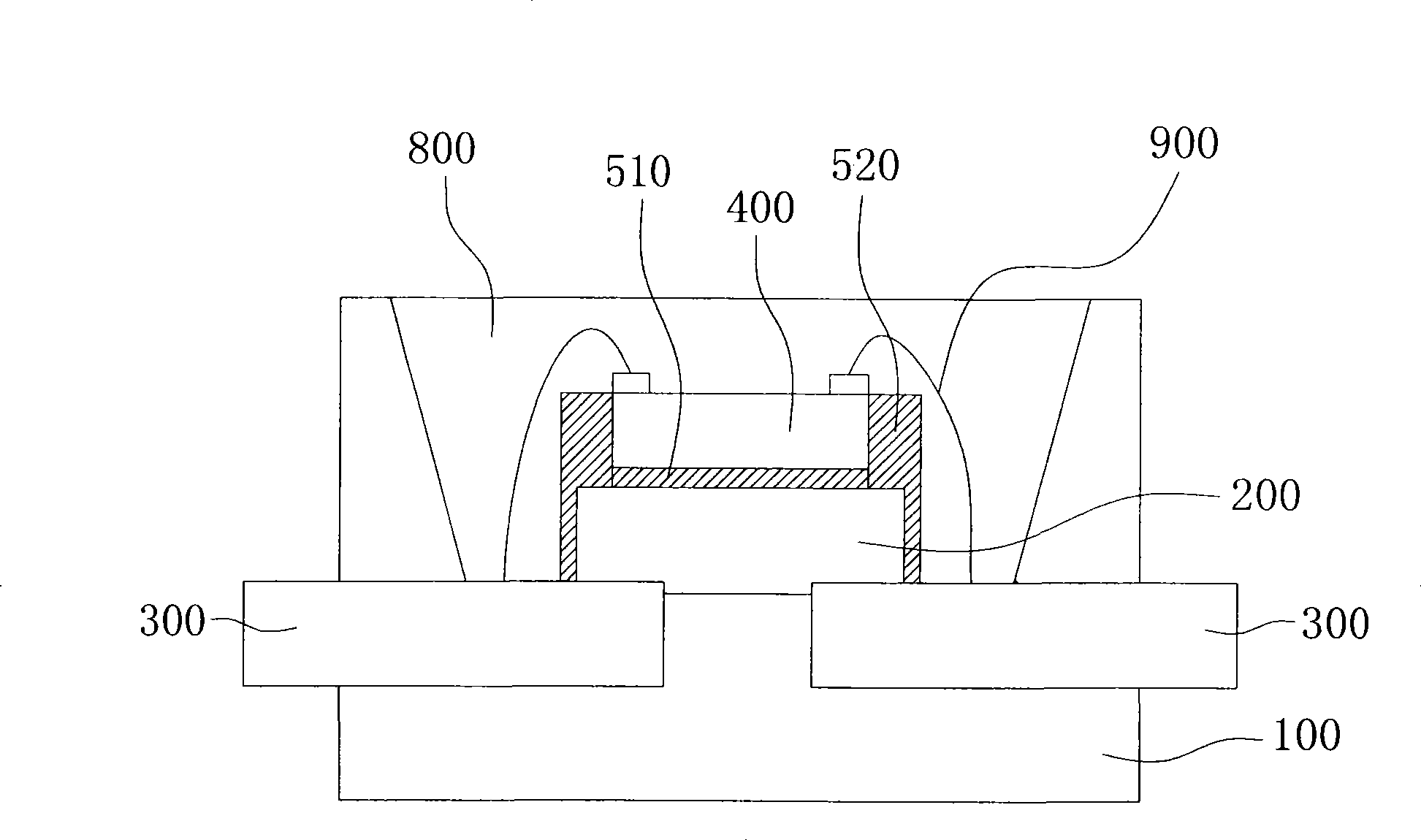

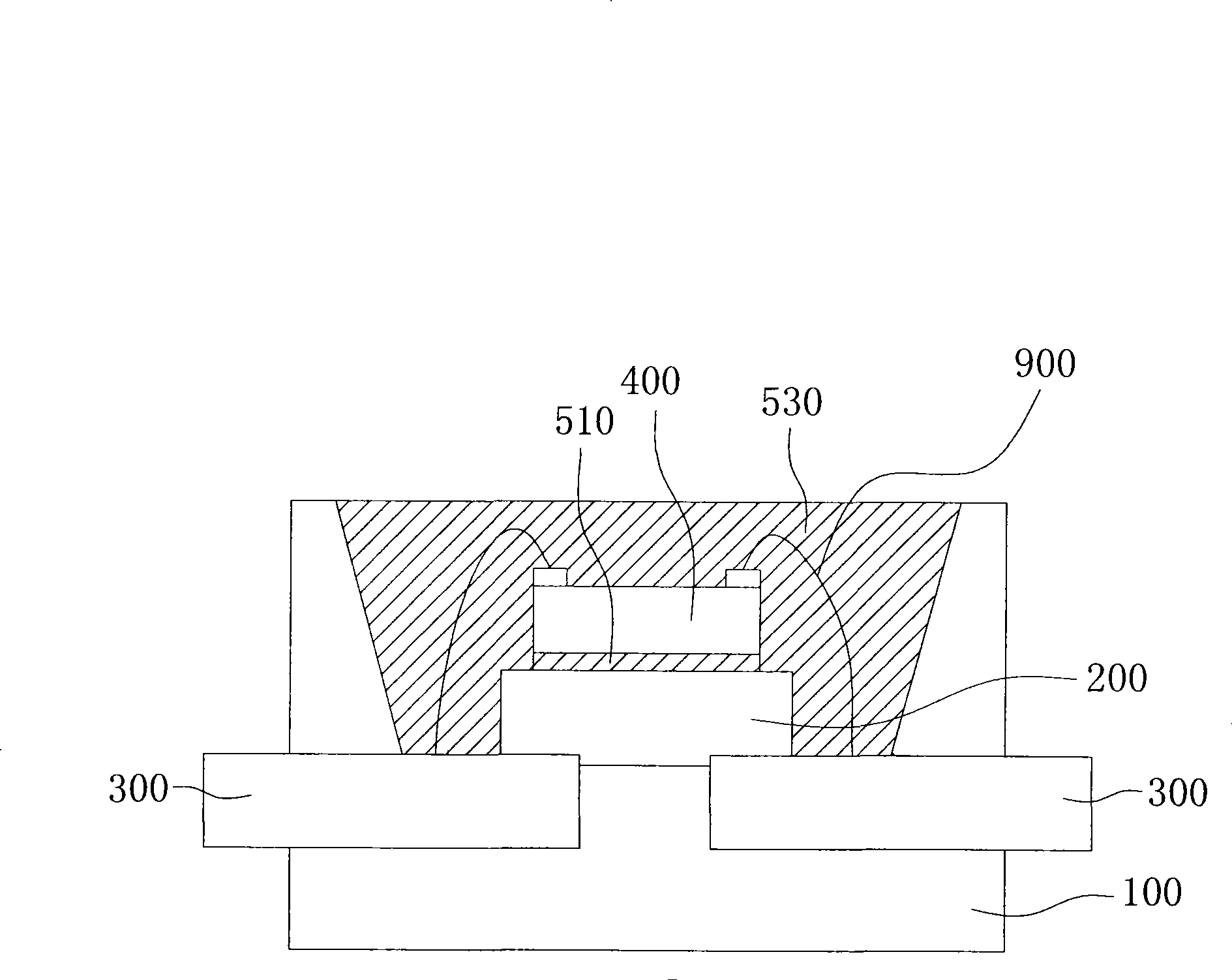

[0032] Please refer to figure 1 , is a schematic structural diagram of the light emitting diode device according to the first embodiment of the present invention. The light emitting diode device of this embodiment includes a base 100 , a substrate 200 , a bracket 300 , an LED chip 400 , a first mixed glue 510 and a packaging glue body 800 .

[0033] The substrate 200 and the bracket 300 are disposed on the base 100 , and the first mixed colloid 510 is coated between the substrate 200 and the LED chip 400 to fix the LED chip 400 on the substrate 200 . The LED chip 400 is connected to the bracket 300 by a wire 900 for conducting power to make the LED chip 400 emit light upward (FaceUp). The packaging glue body 800 is poured into the base 100 to cover the substrate 200 , the LED chip 400 and the wire 900 .

[0034] The first m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com